Preparation method of high-tap-density small-granularity sphere-like silver powder for LTCC (low temperature co-fired ceramic) inner electrode

A technology with small particle size and spherical shape, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of wide particle size distribution of silver powder, difficulty in solid-liquid separation process, high content of organic impurities, etc., and achieve low cost and low equipment requirements. High, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

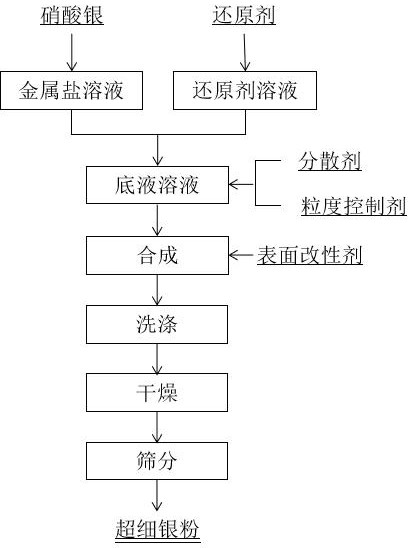

[0028] like figure 1 As shown in the figure, a preparation method of high-vibration small-sized spherical silver powder for LTCC inner electrode, comprising the following steps:

[0029] (1) Dissolve silver nitrate in pure water to obtain a silver nitrate solution with a concentration of 250~300g / L, and keep the temperature at 25~30℃.

[0030] (2) Dissolve the reducing agent in pure water to obtain a reducing agent solution with a concentration of 100~180g / L, and keep the temperature at 25~30℃; the reducing agent refers to any one of glucose, hydroquinone and hydrazine hydrate.

[0031] (3) Dissolving the dispersant and particle size control agent in pure water to obtain a bottom liquid solution, the temperature is kept at 25~30℃; the addition amount of the dispersant in the bottom liquid solution is 100~200g / L, and the addition amount of the particle size control agent is 0.27~ 5.0g / L; dispersant refers to one of lactic acid, polyvinylpyrrolidone and gelatin; particle size c...

Embodiment 1

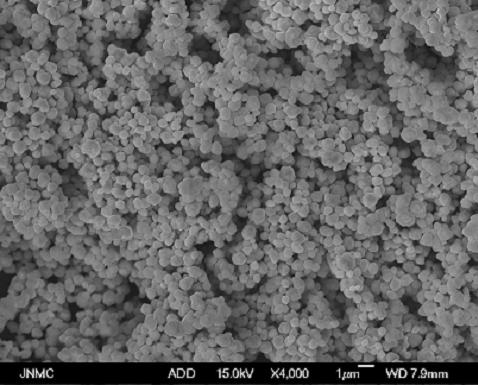

[0036] Embodiment 1 A preparation method of high-vibration small-sized spherical silver powder for LTCC inner electrode, comprising the following steps:

[0037] (1) Dissolve 250 g of silver nitrate in 1 L of pure water to obtain a silver nitrate solution, and keep the temperature at 25 °C.

[0038] (2) Dissolve 180 g of glucose in 1 L of pure water to obtain a reducing agent solution, and keep the temperature at 25 °C.

[0039] (3) Dissolve 200g of polyvinylpyrrolidone and 1.8g of ammonia water in 1L of pure water to obtain a bottom liquid solution, and keep the temperature at 25°C.

[0040] (4) Add the silver nitrate solution and the reducing agent solution to the bottom solution and stir them in parallel. Get silver dust.

[0041] Wherein: the surface modifier solution refers to the solution obtained by dissolving 0.8 g of polyacrylamide in 0.05 L of absolute ethanol. ⑸ Wash the silver powder until the conductivity of the washing liquid is less than or equal to 20μs, the...

Embodiment 2

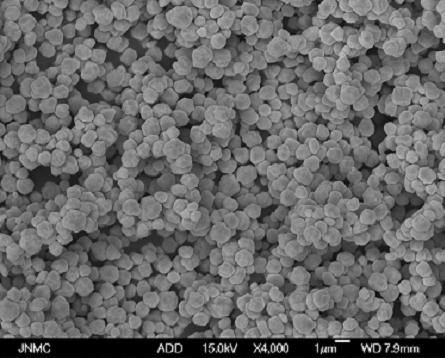

[0044] Embodiment 2 A preparation method of high-vibration small-sized spherical silver powder for LTCC inner electrode, comprising the following steps:

[0045] (1) Dissolve 250 g of silver nitrate in 1 L of pure water to obtain a silver nitrate solution, and keep the temperature at 30 °C.

[0046] (2) Dissolve 180 g of glucose in 1 L of pure water to obtain a reducing agent solution, and keep the temperature at 30 °C.

[0047] (3) Dissolve 200g of polyvinylpyrrolidone and 1.0g of ammonia water in 1L of pure water to obtain a bottom liquid solution, and the temperature is kept at 30°C.

[0048] (4) Add the silver nitrate solution and the reducing agent solution to the bottom liquid solution in cocurrent flow and stir, the cocurrent addition speed is 100mL / min, the solution addition time is 10min, and the stirring speed is 600rpm. After 20 minutes of reaction, the surface modifier solution was added to obtain silver powder.

[0049] Wherein: the surface modifier solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com