Preparation method of corynoxine

A drying and flow technology, applied in the biological field, can solve the problems of poor process reproducibility, low product yield, low extraction efficiency, etc., and achieve the effects of high extraction efficiency, high product purity, and simple method operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

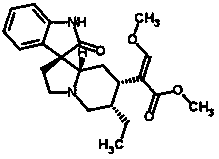

Image

Examples

Embodiment 1

[0017] Take 2kg of dried Uncaria macrophyllum, crush it into 60 meshes, put it in a CO2 supercritical extraction tank, feed liquid CO2, the flow rate is 3ml / min / g raw material, and feed chloroform as entrainer at the same time, the flow rate is 2ml / min / g , the raw material extraction temperature is 45°C, the pressure is 20Mpa, the extraction time is 2h, the analytical extract is dissolved in 75% methanol solution, and the liquid is collected by a short column of neutral alumina (basic alumina particle size 120 mesh) and concentrated to obtain an extract. Take chloroform, methanol, water, mix according to 3:2:3, take the upper phase as the stationary phase, the host speed is 850rpm, the lower phase is the mobile phase, the flow rate is 3ml / min, the ultraviolet detector is online monitoring, and the collected fraction is dried under reduced pressure , to get 2.9g coronocine base, detected by HPLC, the content was 98.5%.

Embodiment 2

[0019] Take 2kg of dried Uncaria macrophyllum, crush it into 20 meshes, put it in a CO2 supercritical extraction tank, feed liquid CO2, the flow rate is 2ml / min / g raw material, and feed chloroform as entrainer at the same time, the flow rate is 2ml / min / g , the raw material extraction temperature is 30°C, the pressure is 25Mpa, and the extraction time is 3h. The analytical extract is dissolved in 80% methanol solution, passed through a short column of neutral alumina (basic alumina particle size 120 mesh) to collect and concentrate the liquid in the lower column to obtain an extract. Take chloroform, methanol, water, mix according to 5:5:7, take the upper phase as the stationary phase, the speed of the host is 800rpm, the lower phase is the mobile phase, the flow rate is 3ml / min, the ultraviolet detector is online monitoring, and the collected fraction is dried under reduced pressure , to get 3.1g coronocine base, detected by HPLC, the content was 97.1%.

Embodiment 3

[0021] Take 2kg of dried Uncaria macrophyllum, crush it into 80 meshes, put it in a CO2 supercritical extraction tank, feed liquid CO2, the flow rate is 5ml / min / g raw material, and feed chloroform as entrainer at the same time, the flow rate is 1ml / min / g , the raw material extraction temperature is 50°C, the pressure is 23Mpa, the extraction time is 2h, the analytical extract is dissolved in 90% methanol solution, and the liquid is collected by a short column of neutral alumina (basic alumina particle size 120 mesh) and concentrated to obtain an extract. Take chloroform, methanol, and water, mix according to 4:3:5, take the upper phase as the stationary phase, and the lower phase as the mobile phase, the host speed is 900rpm, the flow rate is 2ml / min, the ultraviolet detector is monitored online, and the collected fraction is dried under reduced pressure , to get 3.3g coronocine base, detected by HPLC, the content was 97.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com