A mechanical strong torsion plunger rotator

A rotator, torsion type technology, applied in the field of mechanical strong torsion plunger rotator, can solve the problem of not being able to meet the anti-eccentric wear of the sucker rod string, achieve the effect of compact structure, reduce pump jamming, and prolong the maintenance-free period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The example of the present invention is a device installed on the mechanical oil production rod string of the rod pump in the pumping well, which is used for the anti-eccentric wear of the rod string, and the tension-compression alternating force of the rod string in the up and down strokes along the straight line in the opposite direction, The purely mechanical mechanism is used to convert the one-way circular force that forces the rotating body to perform directional rotation.

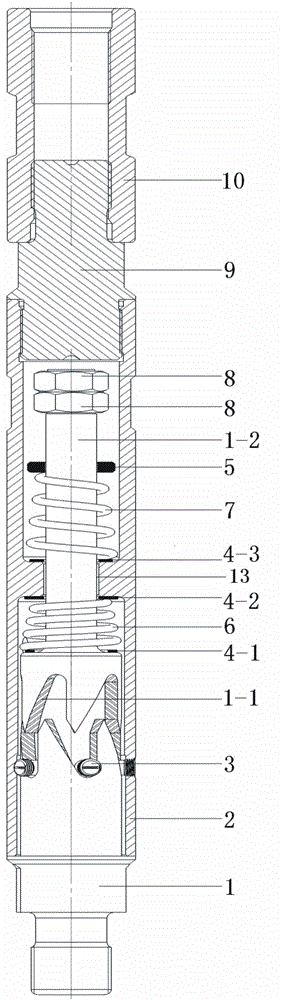

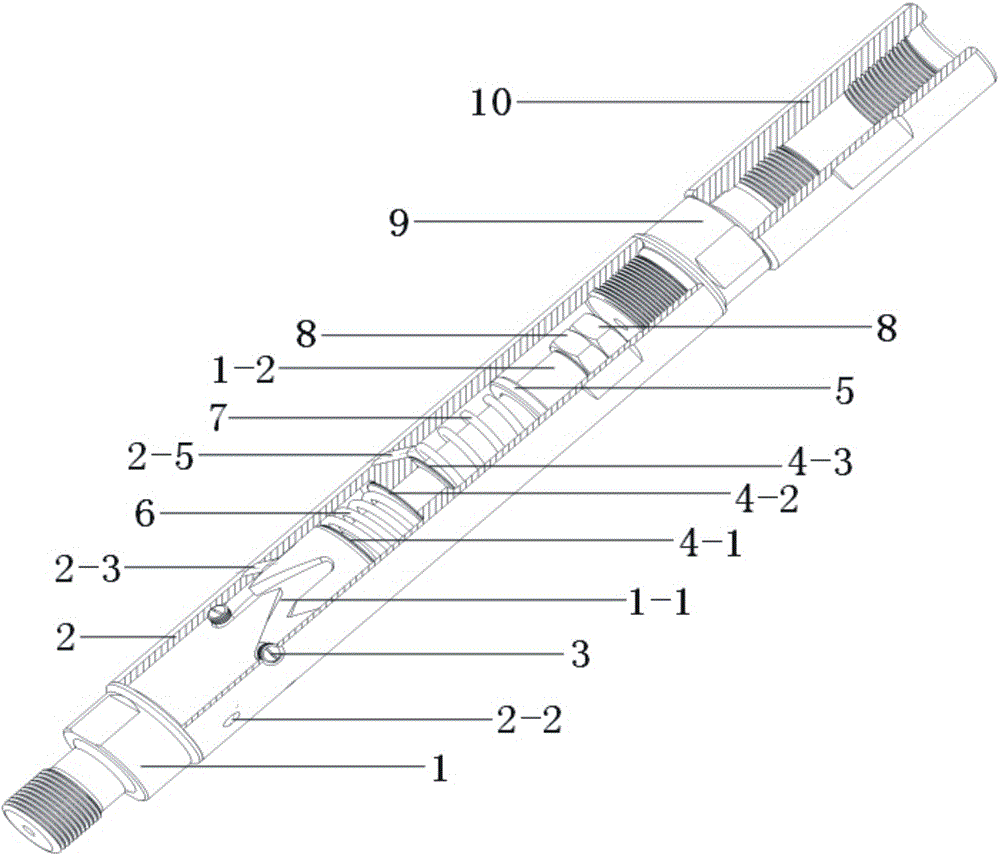

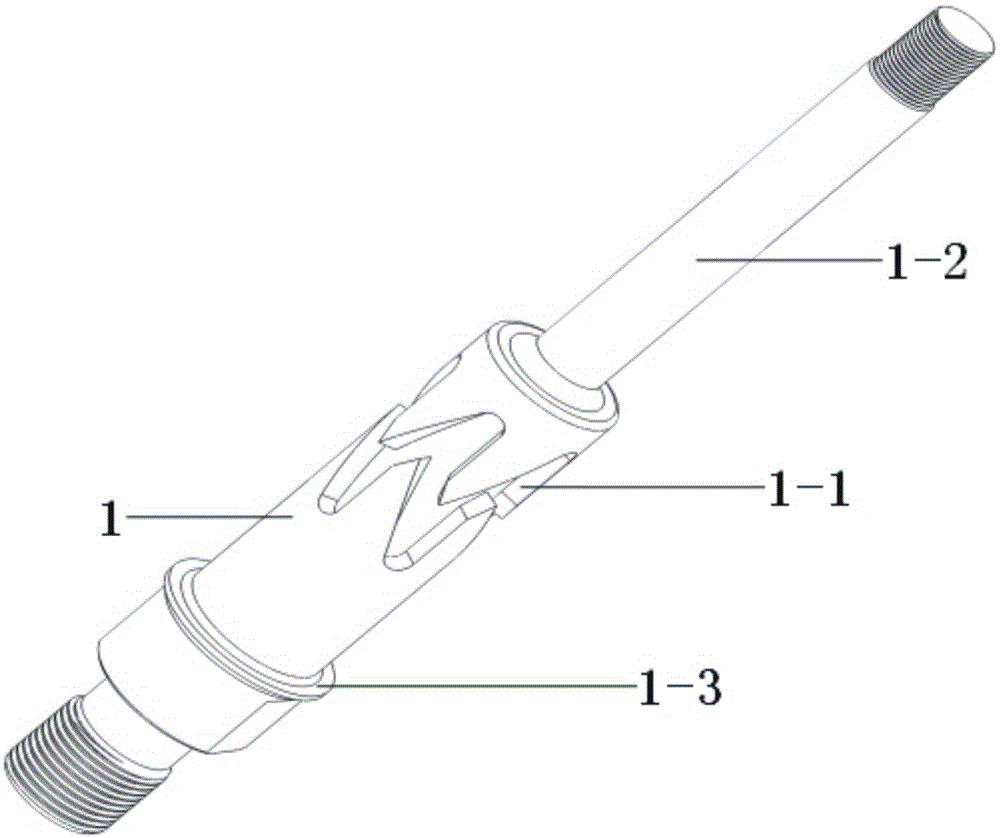

[0037] figure 1 Shown is a planar cross-sectional view of a mechanical strong torsion plunger rotator according to an embodiment of the present invention. The mechanical strong torsion plunger rotator includes a rotating body 1, a driving part 2, a slider pin 3, a spring washer 4-1, a spring washer 4-2, a spring washer 4-3, a spring support piece 5, and a lower chamber Chamber spring 6, upper chamber spring 7, buckle nut 8, connector 9 and collar 10. Except the slider pin 3, all other compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com