Coarse-fine motion integrated magnetic-levitation mask platform system

A mask stage, coarse and fine movement technology, applied in the field of lithography machine mask stage system, can solve the problems of increasing the burden of the underlying linear motor, limiting the movement accuracy of the mask stage, complex system structure, etc., achieving easy lightweight design, The effect of realizing lightweight design and simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific structure, mechanism and working process of the present invention will be further described below in conjunction with the accompanying drawings.

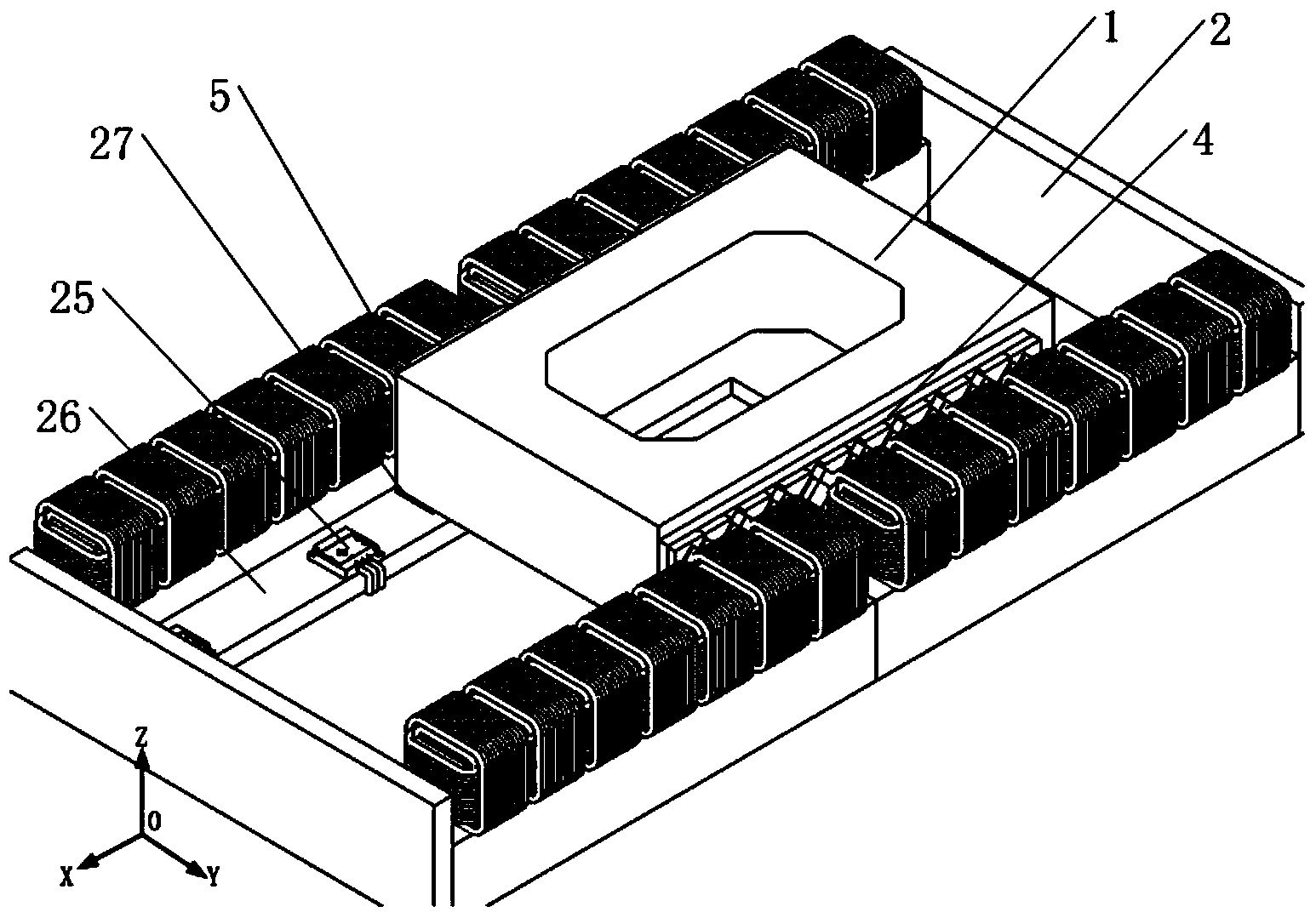

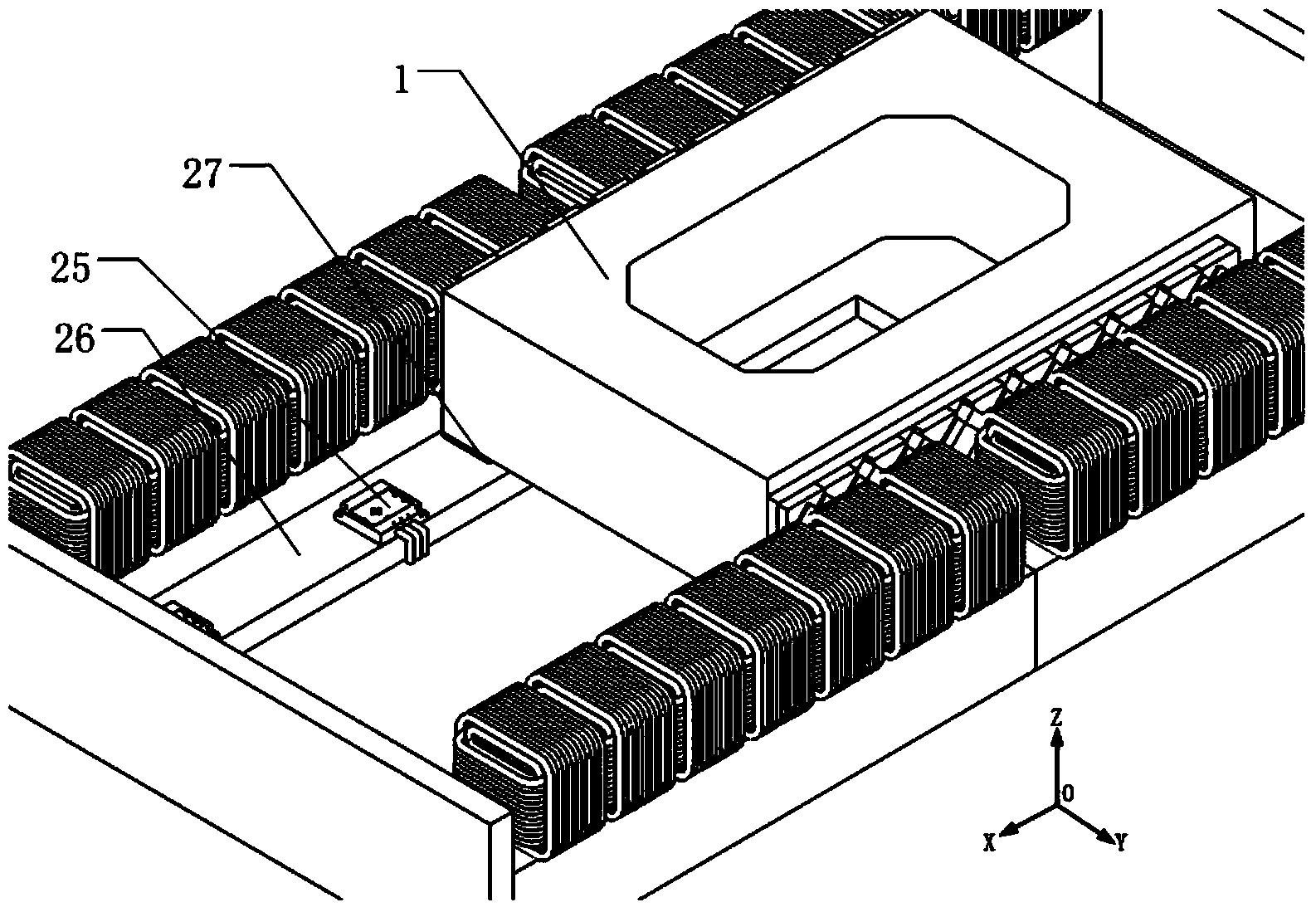

[0024] The present invention provides a maglev mask stage system with integrated coarse and fine movement, such as figure 1 and figure 2 As shown, the system includes a mask stage body 1, a drive motor and a frame 2. The mask stage body 1 is located in the middle of the mask stage system, and the mask stage body 1 is thin-walled The shell is made of silicon carbide ceramic material.

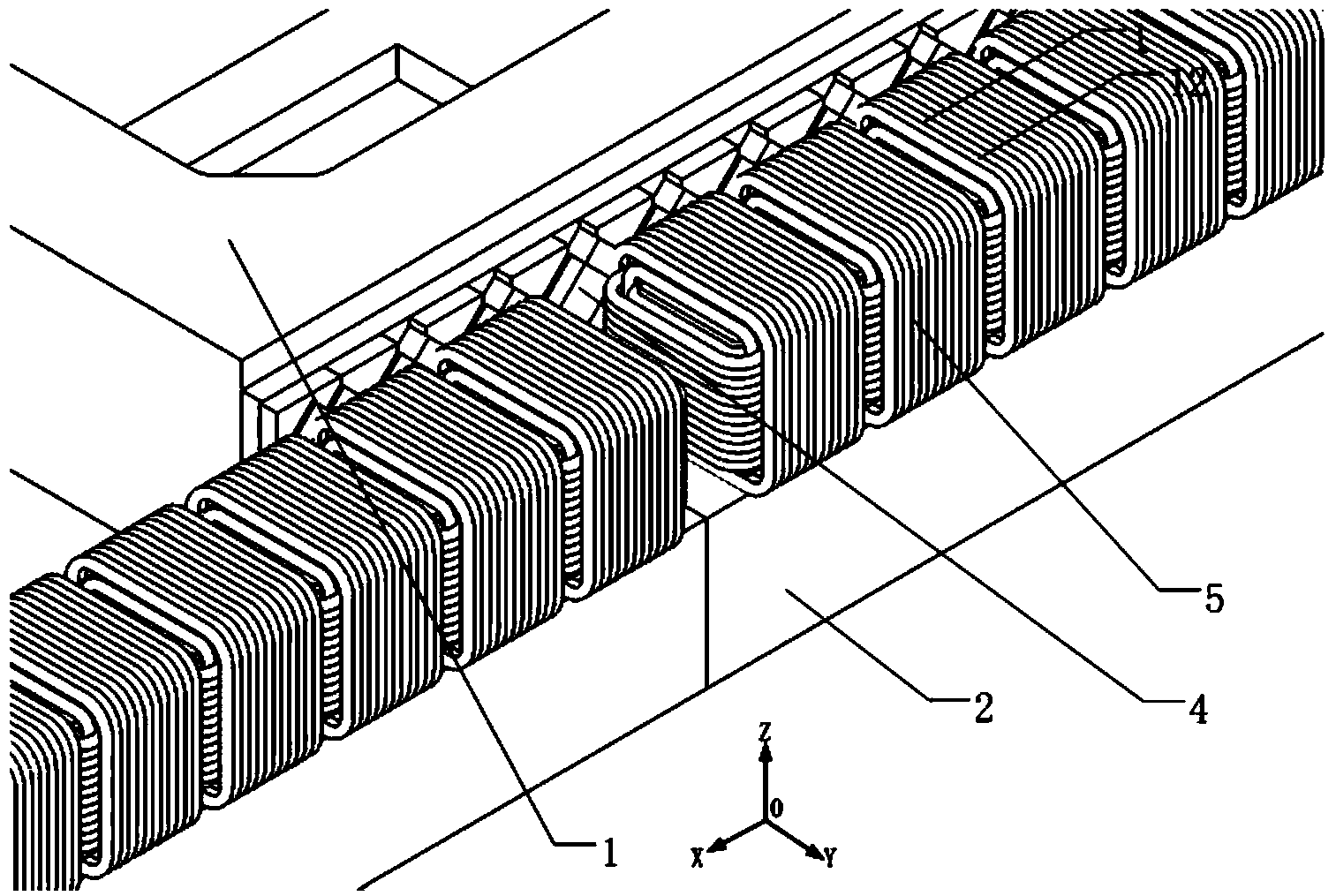

[0025] The drive motor of a kind of maglev mask table system with coarse and fine motion integrated in the present invention adopts a moving iron type maglev planar motor, (such as image 3 shown); there are two drive motors, each of which contains a coil array 5 fixed on the frame 2 and a permanent magnet array 4 fixed on the mask table body 1, which are symmetrically arranged between the mask table and the The direction of mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com