Data acquisition and monitoring system of vacuum pressure die-casting machine

A vacuum die-casting and monitoring system technology, applied in transmission systems, signal transmission systems, electrical signal transmission systems, etc., can solve problems such as inability to perform network statistics, inability to identify mold information, inability to remotely monitor vacuum die-casting machine systems, etc., to achieve The effect of simple structure and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

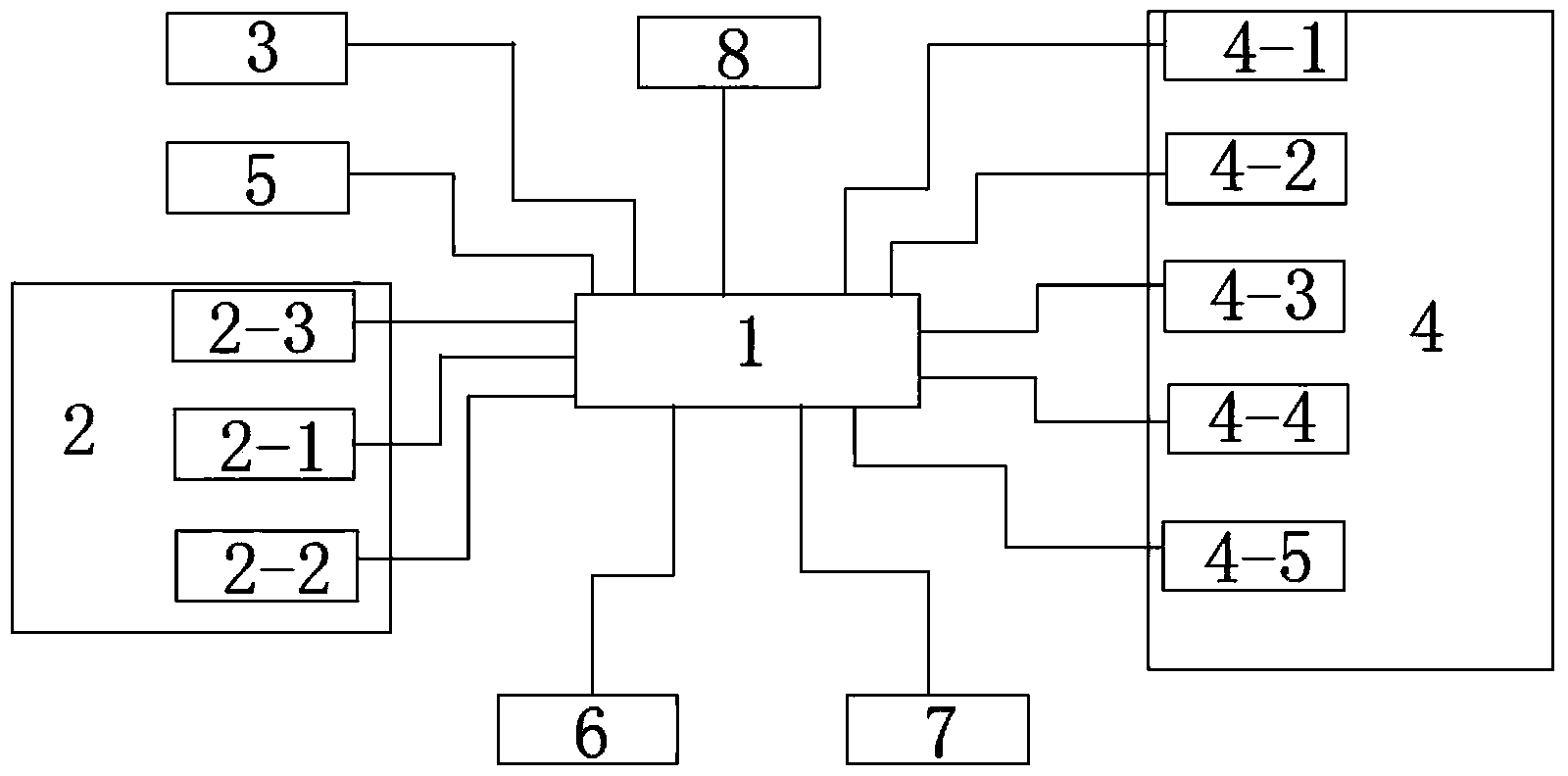

[0021] Such as figure 1 The data acquisition and monitoring system of the vacuum die-casting machine shown includes a hardware circuit board and software. The hardware circuit board includes a central processing module 1, a die-casting machine monitoring module 2, an IO input and output module 3, five serial communication interfaces 4, and data storage Module 5, power supply module 6, communication module 7 and JTAG debugging interface module 8; described central processing module 1 adopts STM32F103 processor, described communication module 7 adopts 10 / 100M Ethernet communication system, in described IO input and output module 2 There are sixteen input and eight output channels; the central processing module 1 is connected with the die casting machine monitoring module 2, IO input and output module 3, five serial communication interfaces 4, data storage module 5, power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com