Three-frequency dual polarization cone conformal micro-strip antenna array

A microstrip antenna and dual-polarization technology, applied to antenna arrays, antenna unit combinations with different polarization directions, antennas, etc., to increase communication capacity and achieve omnidirectional coverage of beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

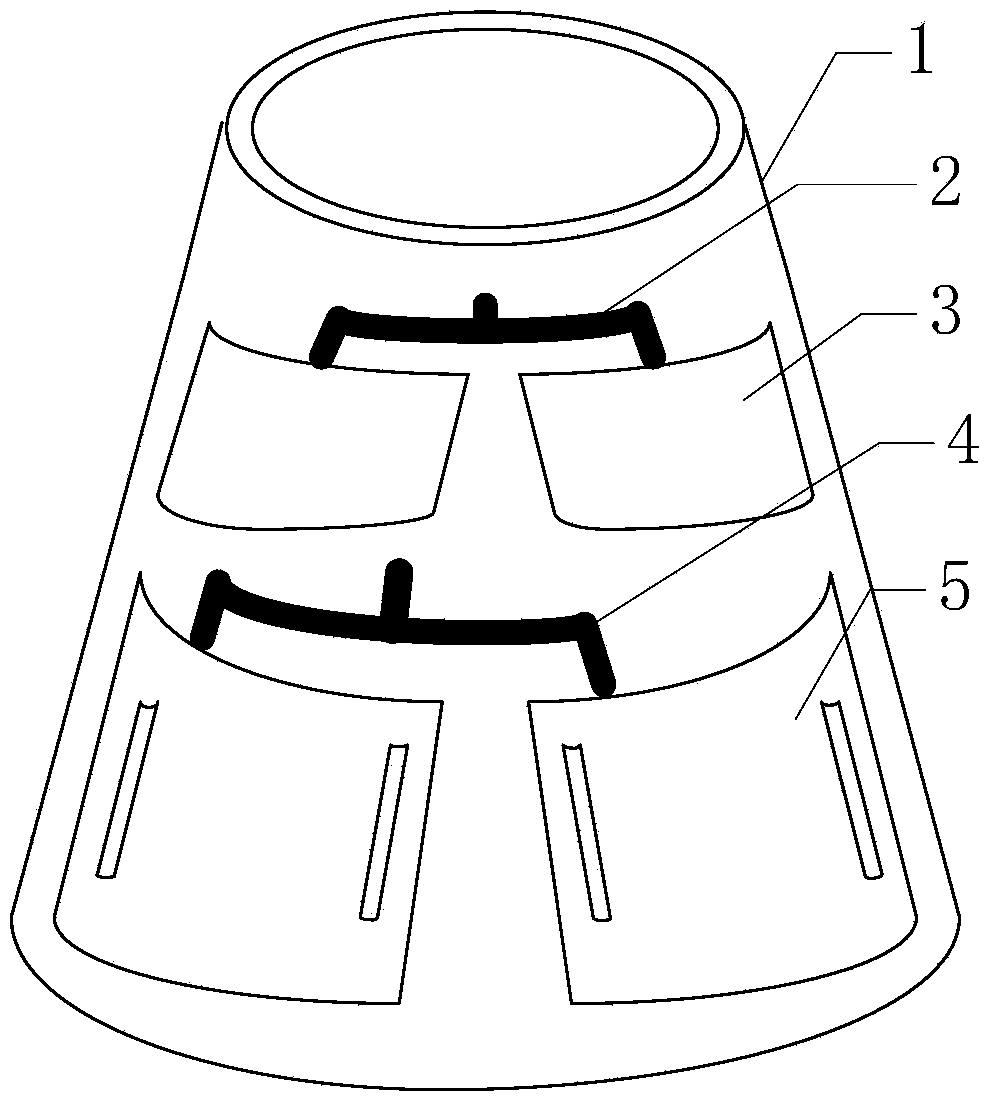

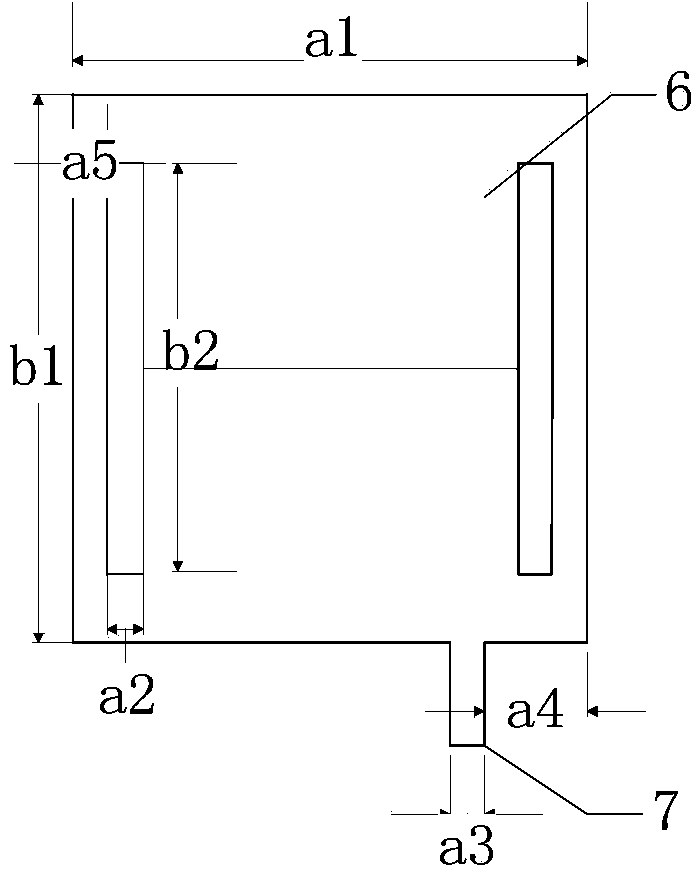

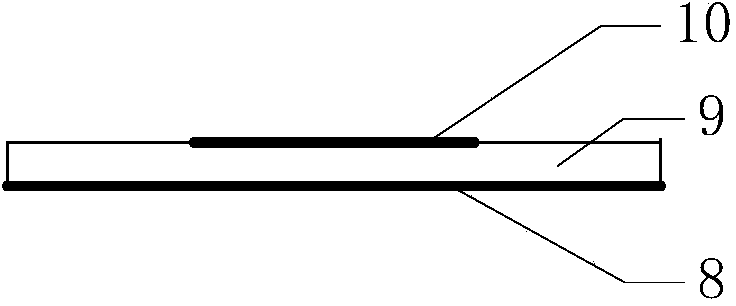

[0016] A triple-frequency dual-polarized conical conformal microstrip antenna array of the present invention includes a conical carrier 1, a first microstrip line 2, a first microstrip antenna array 3, a second microstrip line 4 and a second microstrip antenna Array 5, the first microstrip antenna array 3 and the second microstrip antenna array 5 are all arranged on the outer surface of the conical carrier 1, and uniformly surround the conical carrier surface, wherein the first microstrip antenna array 3 is located on the second Above the microstrip antenna array 5, wherein the first microstrip antenna array 3 includes four single-frequency microstrip antenna units 11, the four single-frequency microstrip antenna units 11 are connected in parallel through the first microstrip line 2, and the second microstrip The antenna array 5 includes four dual-band microstrip antenna units 6 connected in parallel through the second microstrip line 4 .

[0017] The single-frequency microstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com