Interferometer for tsv detection and detection method using the interferometer

An interferometer, detection object technology, applied in semiconductor/solid-state device testing/measurement, instruments, measurement devices, etc., can solve the problems of less light quantity, large result data capacity, long detection time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

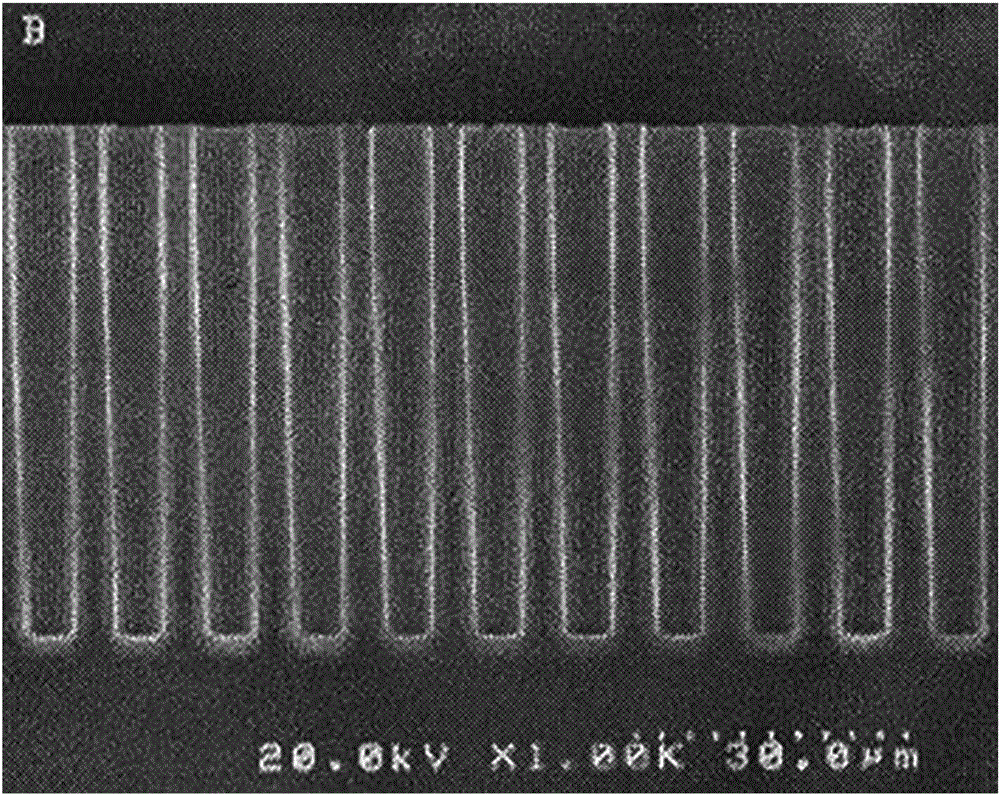

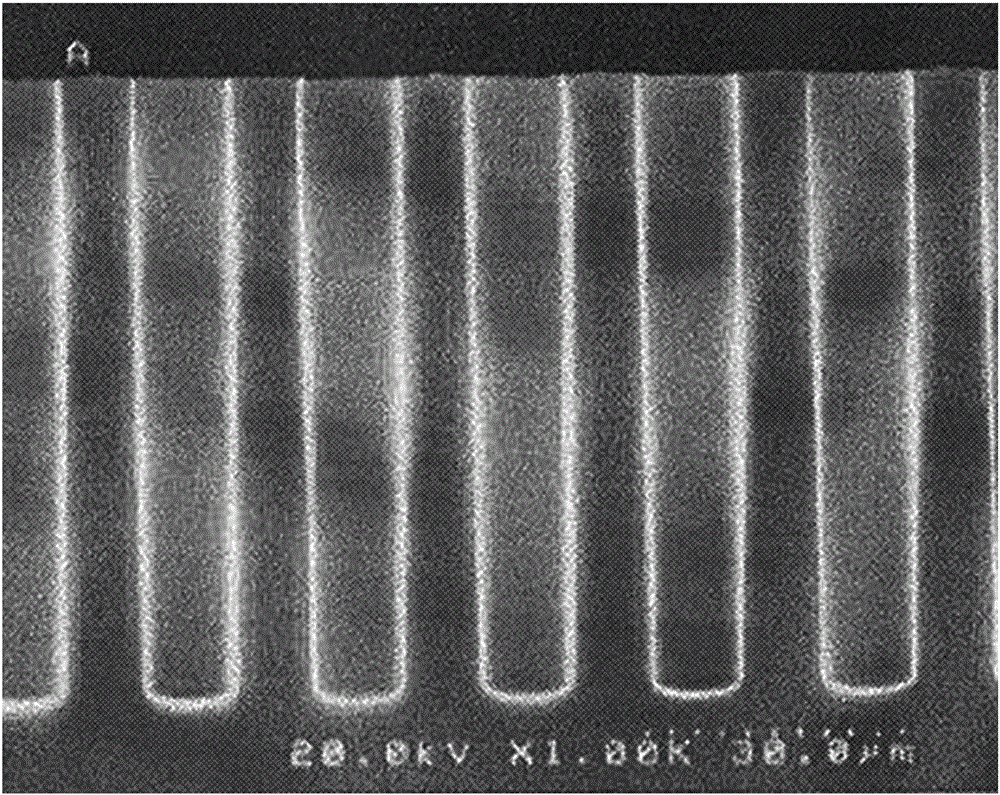

[0062] Prepare the substrate with TSVs, and use a conventional scanning electron microscope to obtain images such as Figure 5 SEM (Scanning Electron Microscope, scanning electron microscope) image, and directly measure (measured) the diameter and depth of TSV according to the SEM image.

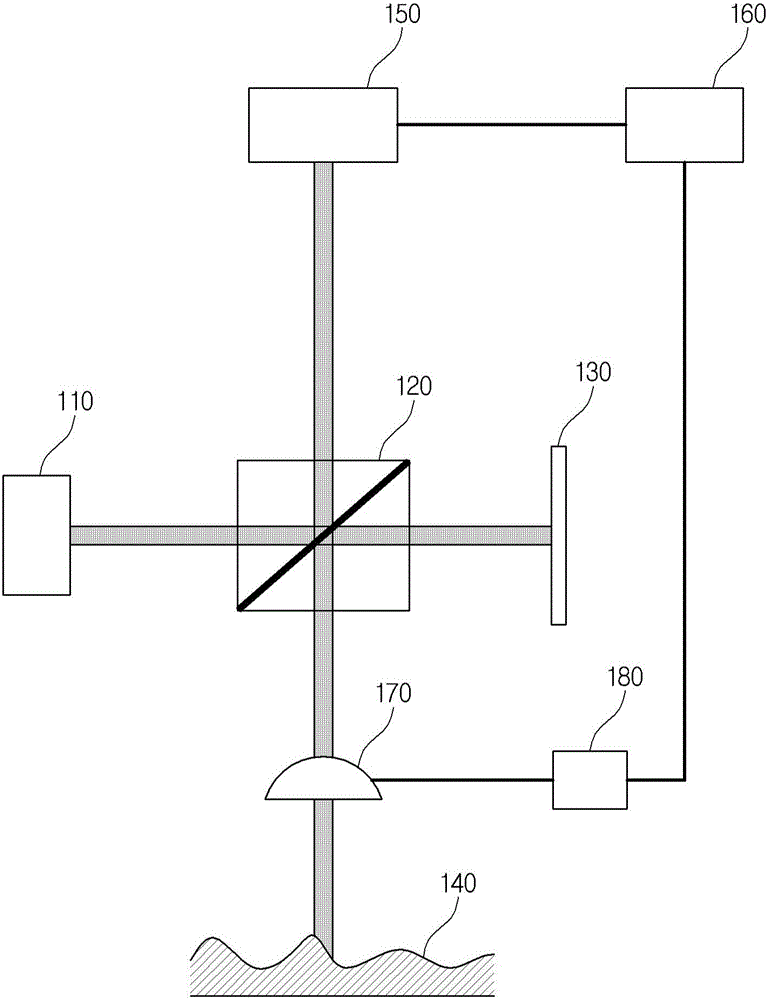

[0063] And, by figure 1 A conventional interferometer using a piezoelectric sensor divides the TSV into predetermined sections and performs continuous scanning to detect the diameter and depth of the TSV.

[0064] Moreover, the focal point is adjusted to the entrance of the TSV, that is, the reference position (TopCD) by the variable field diaphragm 80 of the TSV detection interferometer of the present invention and the first interference signal is acquired, and the variable field diaphragm 80 makes the The focus is adjusted to the bottom surface of the TSV, i.e. the variable position (BottomCD), and the second interference signal is acquired, and the diameter and depth of the TSV are detec...

experiment example 2

[0075] A substrate having a TSV having a shape different from that of Experimental Example 1 was prepared, and the experiment was carried out by the same method as Experimental Example 1 and obtained as follows: Figure 6 SEM image and measured TSV, using such as figure 1 The conventional interferometer and the interferometer for TSV detection of the present invention detect TSVs and acquire the following detection values.

[0076] [Table 2]

[0077]

Top CD(μm)

Bottom CD(μm)

Height(μm)

Measured value of SEM image

11

10

65

Detection value of conventional interferometer

11.0862

6.2675

-53.4829

Detection value of the interferometer of the present invention

11.1556

10.1995

-64.5011

[0078] As in Experimental Example 1, in Experimental Example 2, a value closer to the actual measured value was detected, which indicates that the detected value is more accurate as the diameter of the TSV increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com