Straw field recovery feed machine

A feed machine and field technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of straw not reaching the fineness of feed, low work efficiency, and no place to store straw segments, etc., to reduce breeding costs, The effect of improving work efficiency and shortening harvesting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

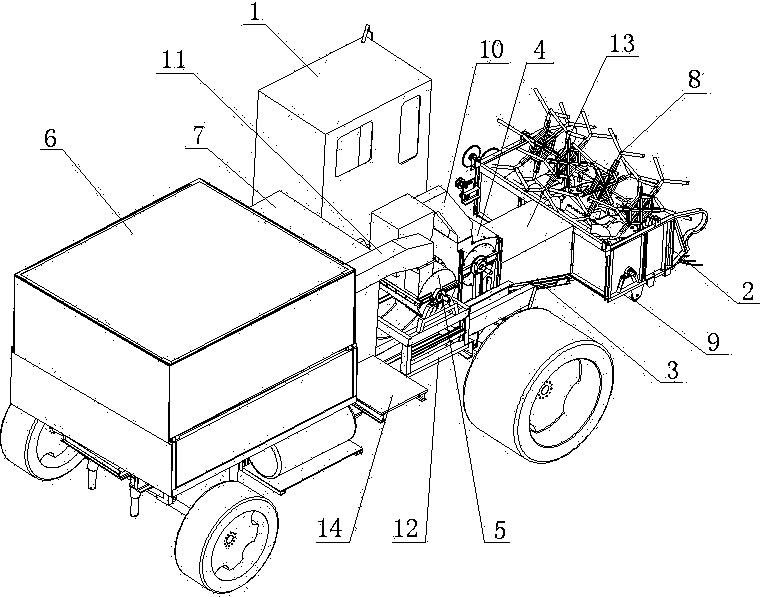

[0010] Attached below figure 1 A straw field recycling feed machine of the present invention will be further described.

[0011] The stalk field recovery feed machine of the present invention is composed of a locomotive, a collector 2, a conveyor belt 3 and a shredder 4; Crusher 5, engine 7 and material storage box 6, base 12 are fixed on the wheel frame by axle, guarantee that base walks synchronously with car body. The front end of the shredder 4 is equipped with a collector 2, and the central outlet of the rear end of the collector 2 is connected to the shredder 4 by the conveyor belt 3, and then conveyed to the kneading machine 5 and the discharge port of the kneading machine 5 by the air duct I10 It is connected to the material storage box 6 through the air duct II11, and the engine 7 of the locomotive is respectively connected with the collector 2, the conveyor belt 3, the shredder 4, and the kneading machine 5.

[0012] A cover tube 13 is provided on the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com