Method for producing pure mountain ginseng lozenge

A production method and technology of wild ginseng, applied in the food field, can solve the problems of affecting the taste of ginseng, reducing the efficacy of medicine, etc., and achieve the effects of shortening the production cycle, improving the health care function, and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

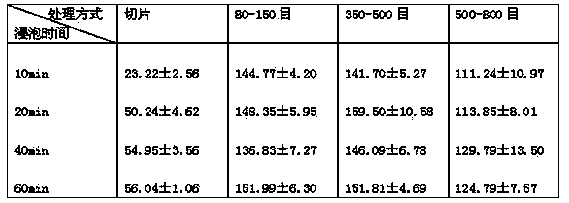

[0044] 1. Grind 2 kg of dried wild ginseng, pass through a 80-150 mesh sieve, mix and extract wild ginseng powder and distilled water three times according to the weight ratio of material to liquid 1:20, each time for 25 minutes, filter, combine the filtrates, and dry the residue.

[0045] 2. Concentrate the filtrate at 60°C to an extract with a relative density of 1.12.

[0046] 3. Mix the dried residue with the extract, add distilled water to dilute to a relative density of 1.35, make wet granules from the mixed wild ginseng extract and residue, and dry at 70°C.

[0047] 4. Tablet pressing A rotary tablet press is used to press into tablets, the specification is 0.35g*9 tablets, 3 plates per box.

[0048] 5. Aluminum-plastic packaging machine is used for inner packaging, and compound bags and cartons are used for outer packaging.

Embodiment 2

[0050] 1. Crush 2 kg of dried wild ginseng, pass through a 350-500 mesh sieve, mix and extract wild ginseng powder and distilled water three times according to the weight ratio of material to liquid 1:20, each time for 20 minutes, filter, combine the filtrates, and dry the residue.

[0051] 2. Concentrate the filtrate at 60°C to an extract with a relative density of 1.12.

[0052] 3. Mix the dried residue with the extract, add distilled water to dilute to a relative density of 1.35, make wet granules from the mixed wild ginseng extract and residue, and dry at 70°C.

[0053] 4. Tablet pressing A rotary tablet press is used to press into tablets, the specification is 0.35g*9 tablets, 3 plates per box.

[0054] 5. Aluminum-plastic packaging machine is used for inner packaging, and compound bags and cartons are used for outer packaging.

Embodiment 3

[0056] 1. Grind 2 kg of dried wild ginseng, pass through a 500-800 mesh sieve, mix and extract wild ginseng powder and distilled water three times according to the weight ratio of material to liquid 1:20, each time for 20 minutes, filter, combine the filtrates, and dry the residue.

[0057] 2. Concentrate the filtrate at 60°C to an extract with a relative density of 1.12.

[0058] 3. Mix the dried residue with the extract, add distilled water to dilute to a relative density of 1.35, make wet granules from the mixed wild ginseng extract and residue, and dry at 70°C.

[0059] 4. Tablet pressing A rotary tablet press is used to press into tablets, the specification is 0.35g*9 tablets, 3 plates per box.

[0060] 5. Aluminum-plastic packaging machine is used for inner packaging, and compound bags and cartons are used for outer packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com