Waste gas purifier

A waste gas purifier and air inlet technology, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of waste discharge pollution, etc., and achieve high economic benefits, high waste heat recycling effect, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

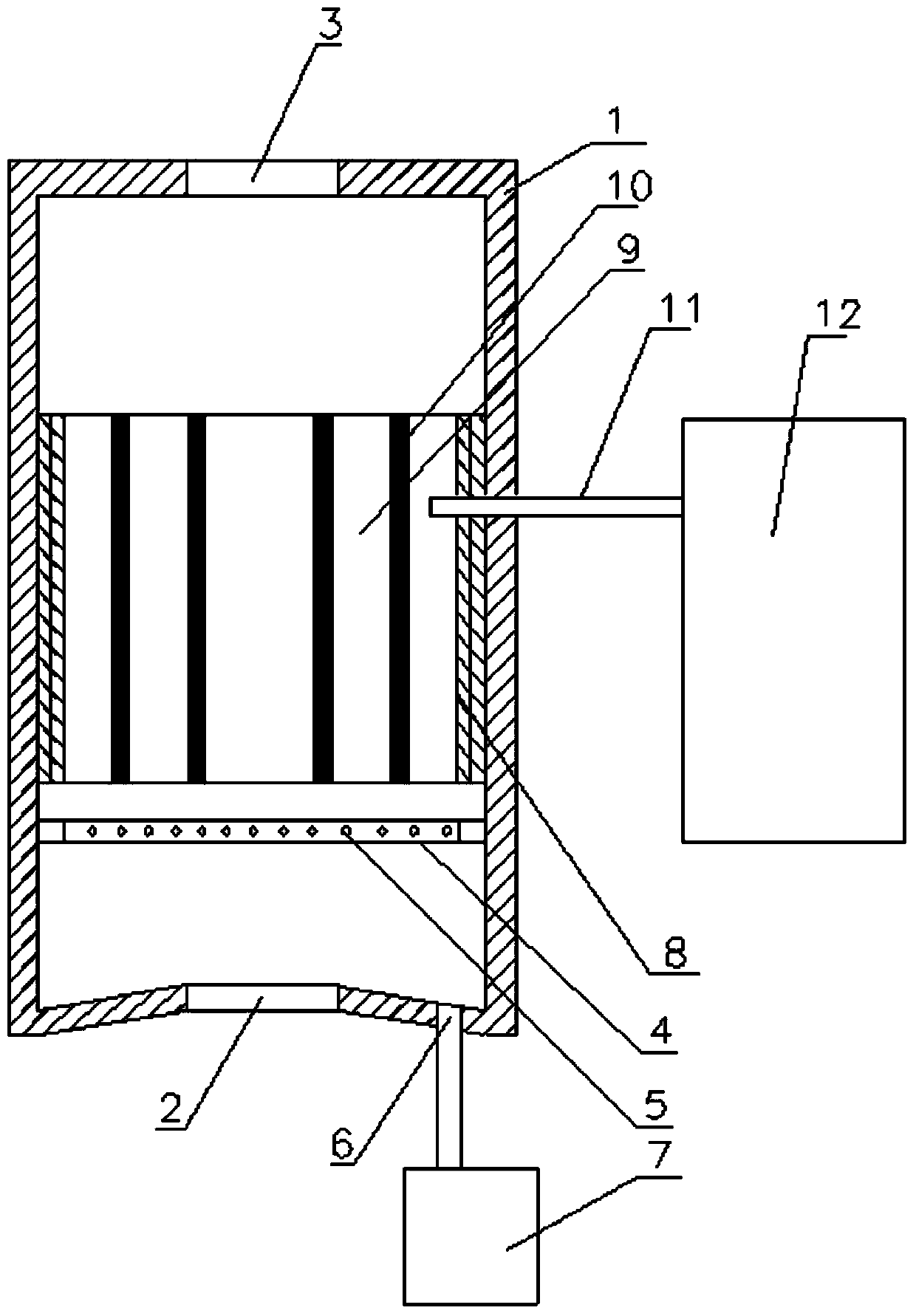

[0015] Such as figure 1 The exhaust gas purifier shown includes a tank body 1, the lower end of the tank body 1 is provided with an air inlet 2, the upper end of the tank body 1 is provided with an air outlet 3, the bottom end surface of the tank body 1 is sunken from the surroundings, and the air inlet 2 is located at the bottom In the center of the end face, an annular water pipe 4 is provided under the inner wall of the tank body 1, and a fine mist high-speed nozzle 5 is provided on the annular water pipe 4, and a hole 6 is provided on the edge of the bottom end of the tank body 1, and a pipe is provided on the hole 6 leading to oil-water separation device 7, wherein the middle section of the inner wall of the tank body 1 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com