Preparation method for TiO2/BiOX nanometer photocatalyst powder

A nano-photocatalyst and powder technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of cheap and easy-to-obtain raw materials, strong degradation ability, and reduced reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

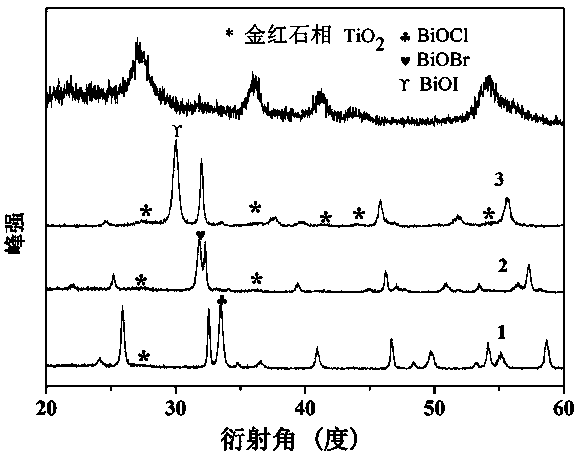

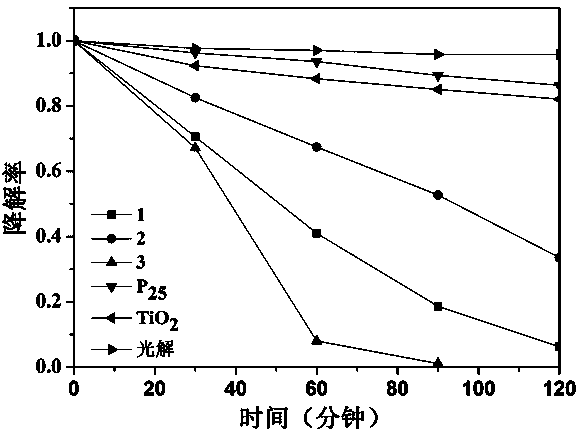

[0020] Rutile Phase TiO 2 / Low temperature preparation of BiOCl nano photocatalyst powder.

[0021] 1) Preparation of titanium precursor: adding titanium compound to alcohol solvent to form a titanium precursor with a concentration of 20 mol / L;

[0022] 2) Stir the titanium precursor formed in step 1) at room temperature for 3 h, then add deionized water, the volume ratio of deionized water to alcohol solvent is 1:5, and continue to stir evenly;

[0023] 3) Preparation of rutile phase nano-TiO 2 Powder: put the solution prepared in step 2) in an oven, heat at 80 °C for 48 h, wash the precipitated solution with water, and then dry at 80 °C to obtain rutile phase nano-TiO with a particle size of 100 nm 2 Powder;

[0024] 4) Preparation of alcohol solution of bismuth-containing compound: adding bismuth-containing compound powder into alcohol solvent to form alcohol solution of bismuth-containing compound with a concentration of 20 mol / L;

[0025] 5) The rutile phase T...

Embodiment approach 2

[0028] Rutile Phase TiO 2 / Low temperature preparation of BiOBr nano photocatalyst powder.

[0029] 1) Preparation of titanium precursor: adding titanium compound to alcohol solvent to form a titanium precursor with a concentration of 0.1 mol / L;

[0030] 2) Stir the titanium precursor formed in step 1) at room temperature for 0.1 h, then add deionized water, the volume ratio of deionized water to alcohol solvent is 1:1, and continue to stir evenly;

[0031] 3) Preparation of rutile phase nano-TiO 2 Powder: Put the solution prepared in step 2) in an oven, heat at 30°C for 12 h, wash the precipitated solution with water, and then dry at 30°C to obtain rutile phase nano-TiO with a particle size of 5 nm 2 Powder;

[0032] 4) Prepare the alcohol solution of the bismuth compound: add the powder of the bismuth compound into the alcohol solvent to form an alcohol solution of the bismuth compound with a concentration of 0.1mol / L;

[0033] 5) The TiO prepared in step 3) 2 T...

Embodiment approach 3

[0036] Rutile Phase TiO 2 / Low temperature preparation of BiOI nano photocatalyst powder.

[0037] 1) Preparation of titanium precursor: adding titanium compound to alcohol solvent to form a titanium precursor with a concentration of 10 mol / L;

[0038] 2) Stir the titanium precursor formed in step 1) at room temperature for 2 h, then add deionized water, the volume ratio of deionized water to alcohol solvent is 1:3, and continue to stir evenly;

[0039] 3) Preparation of rutile phase nano-TiO 2 Powder: put the solution prepared in step 2) in an oven, heat at 60 °C for 24 h, wash the precipitated solution with water, and then dry at 60 °C to obtain rutile phase nano-TiO with a particle size of 80 nm 2 Powder;

[0040] 4) Preparation of alcohol solution of bismuth-containing compound: adding bismuth-containing compound powder into alcohol solvent to form alcohol solution of bismuth-containing compound with a concentration of 10 mol / L;

[0041] 5) The TiO prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com