Tailor welding device for titanium-steel clad plate

A composite plate and plasma welding technology, which is applied in welding equipment, plasma welding equipment, metal processing equipment, etc., can solve the problems of misalignment, large gap between pairing, and large groove error, etc., and achieve precise control of penetration depth, Uniform joint structure and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

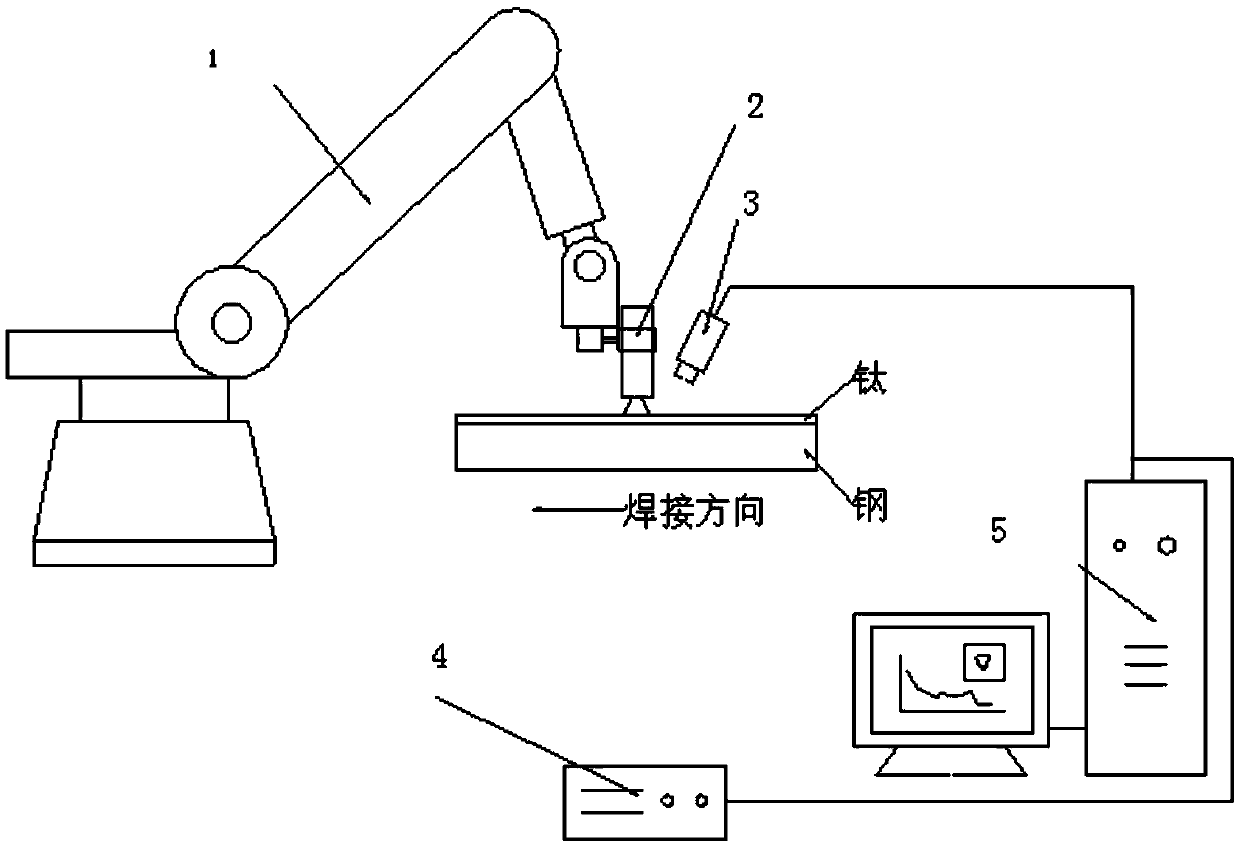

[0015] A tailor welding device for titanium-steel composite panels, comprising a welding robot 1, a plasma welding torch 2, a binocular CCD near-infrared vision sensing device 3, a welding parameter acquisition device 4, and an industrial computer 5, and the plasma welding torch 2 is fixed on the welding robot 1 Forearm flange, binocular CCD near-infrared vision sensing device 3 and welding parameter acquisition device 4 are respectively connected to industrial computer 5 through signal control lines, binocular CCD near-infrared vision sensing device 3 consists of two sets of CCD near-infrared vision Composed of sensing devices, each group of CCD near-infrared vision sensing devices includes a composite filter, lens, CCD camera and image acquisition card, the composite filter, lens, CCD camera are coaxial, and the CCD camera is connected to the image acquisition card; The CCD near-infrared visual sensing device 3 is fixed on the plasma torch 2, and the welding parameter acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com