Wheel-type electrically driven vehicle of modular body

A modular, hub-type technology, applied in vehicle components, motion deposition, power units, etc., can solve problems such as lack of implementation methods and methods, and achieve the effect of being beneficial to effective utilization, energy efficiency improvement, and body weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

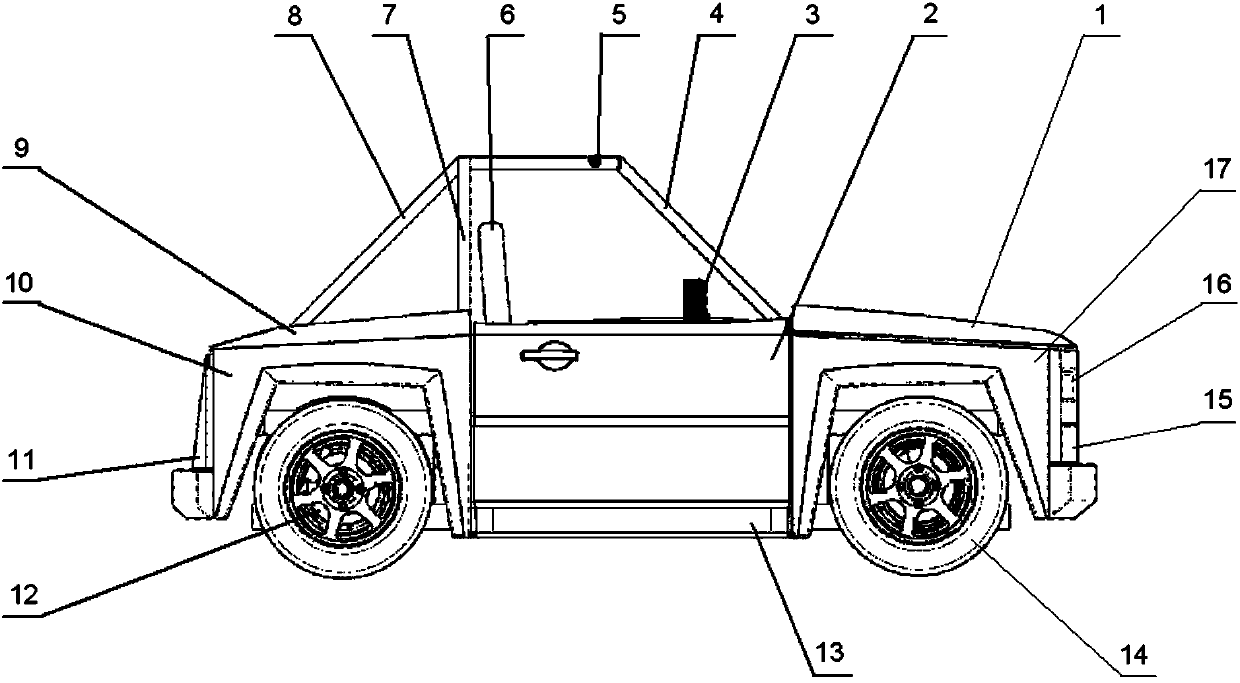

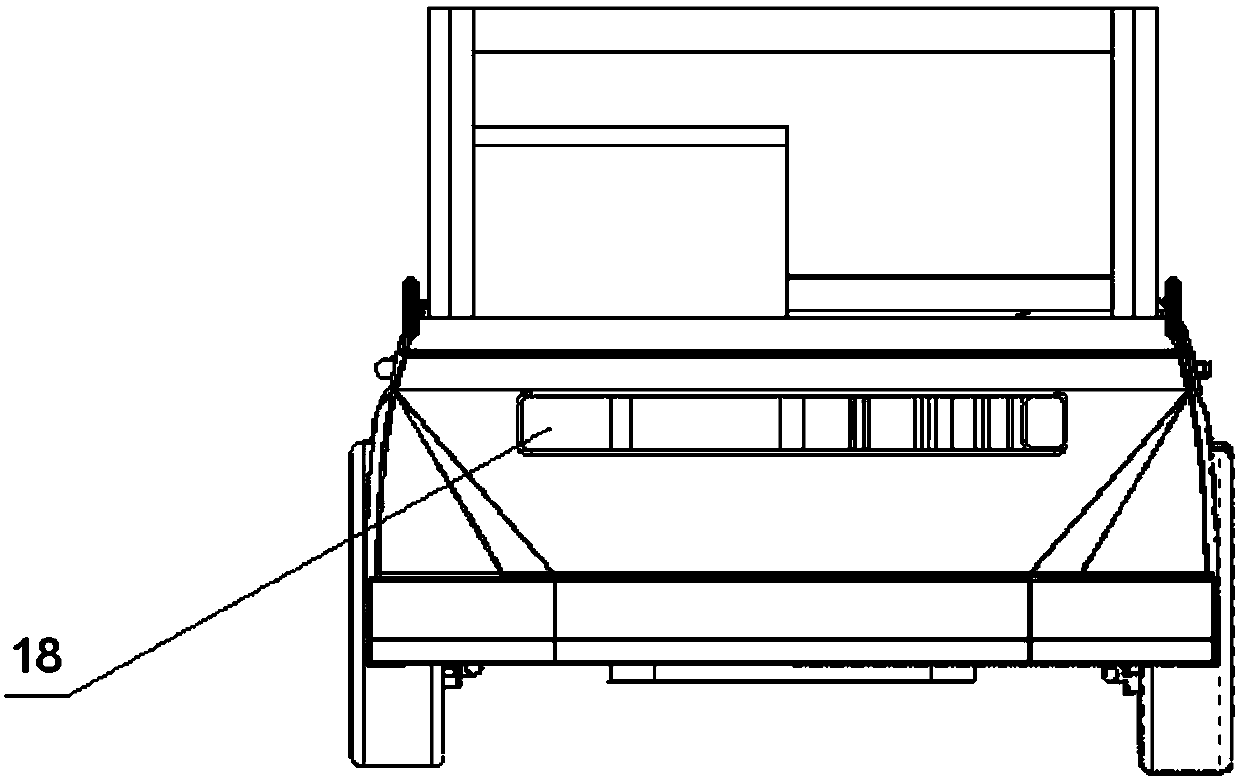

[0032] The modular hub electric drive vehicle of the present invention has a structure such as figure 1 As shown, a modular structure is adopted, including a frame-type body, a modular shell, and a hub drive module installed on the frame-type body chassis. The main structure includes a front cover 1, a door 2, a steering wheel 3, and a front pillar 4 , upper side rail 5, seat 6, center pillar 7, rear pillar 8, rear wall upper cover 9, right rear fender 10, rear wall 11, hub motor 12, lower side rail 13, wheels 14, front support plate 15, front lamp 16, right front fender 17, rear lamp 18, left rear fender 19, left front fender 20. The frame body is made up of aluminum profiles, wherein the front pillar 4, the middle pillar 7 and the rear pillar 8 form the frame of the upper body. A total of four wheels 14 are equipped with in-wheel motors 12, and are connected to the chassis girder through a double wishbone suspension. The four wheels can simultaneously drive the entire vehic...

Embodiment 2

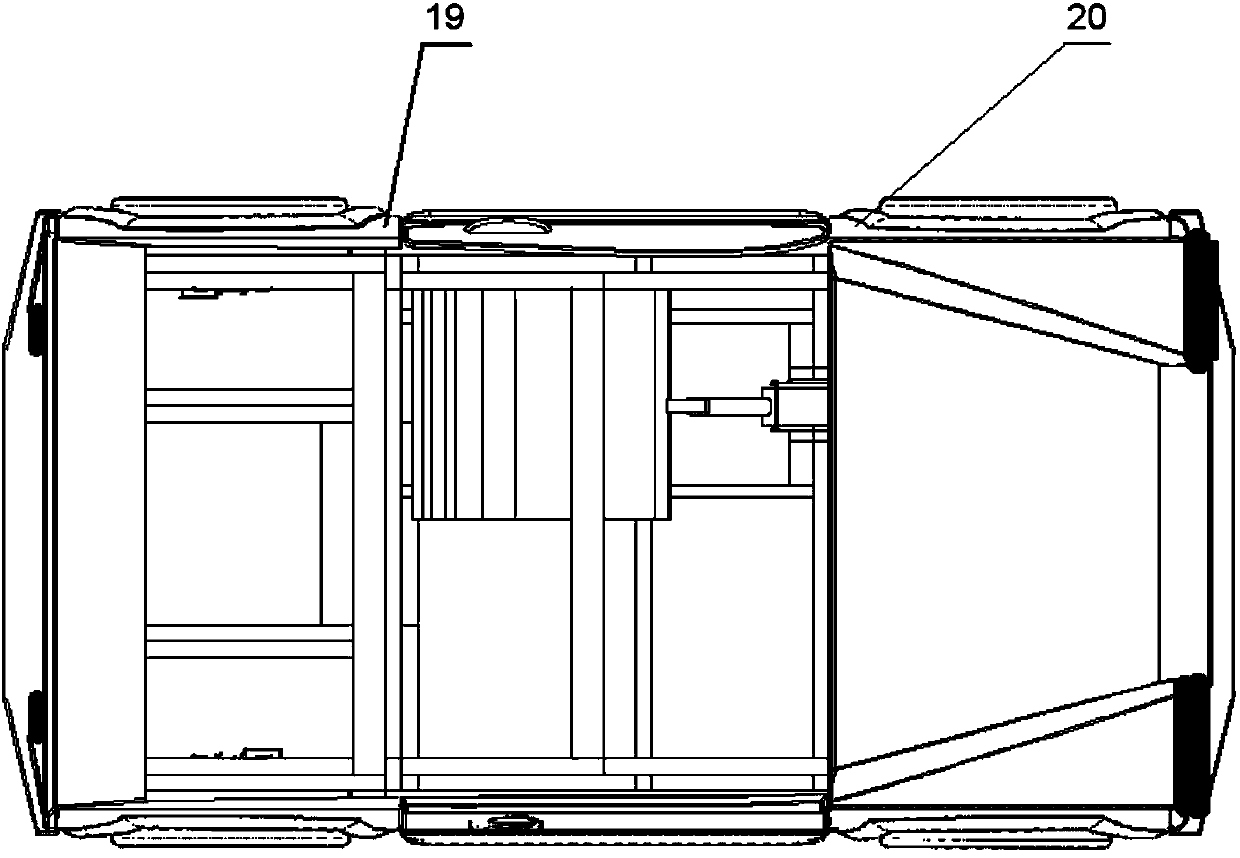

[0034] The modular hub electric drive vehicle of the present invention has a structure such as figure 2 As shown, another different appearance of the car shell can be obtained through the front support plate 15, the front cover plate 1, the car door 2, the rear wall upper cover plate 9, and the rear wall plate 11.

Embodiment 3

[0036] A vehicle with a modular body and wheel-hub electric drive adopts a modular structure, including a frame-type body, a modular shell, and a wheel-hub drive module installed on the chassis of the frame-type body.

[0037] The hub drive module includes hub motors, double-wishbone suspensions and cables. There are four hub motors, which are respectively connected to the wheels and directly drive the four wheels of the vehicle. The hub motors are connected to the frame-type body chassis through double-wishbone suspensions. On the girder, cables transmit drive signals. The hub motor is a 4kW small hub motor with a maximum speed of 750rpm. The four in-wheel motors drive the vehicle simultaneously through two sets of inverters, and the four-wheel in-wheel motors are directly driven without gearboxes and transmission shafts, greatly improving energy efficiency.

[0038]The frame-type body is composed of a front frame, a middle frame and a rear frame made of aluminum profiles. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com