Method for processing sewage with high-concentration phenol and ammonia

A high-concentration, sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of excessive discharge of coal chemical wastewater and reduce incomplete separation and loss Small amount, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

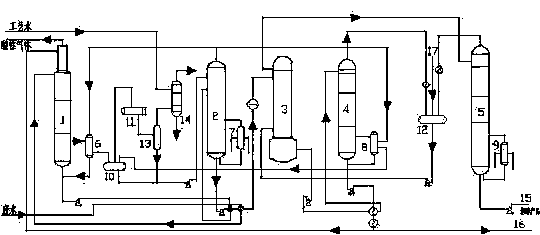

Embodiment 1

[0026] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 16522 mg / L, free ammonia 1334 mg / L, fixed ammonia 1451 mg / L, CO 2 1625 mg / L, pH value is 7.8, water temperature is 75°C, flow rate is 55 t / h, press figure 1Process shown. The extraction tower adopts a packed tower, the feed ratio of backwater to wastewater is 1:4, the volume ratio of extractant butyl acetate to wastewater is 1:8, the temperature at the top of the deacidification tower is 29°C, the pressure is 0.3MPa, the temperature at the bottom of the tower is 90°C, and the pressure is 0.35 MPa, the reflux ratio is 0.4. The pressure at the top of the deamination tower is 0.3MPa, the temperature is 95°C, the pressure at the bottom of the tower is 0.9MPa, and the temperature is 160°C; the pressure at the top of the solvent recovery tower is 0.15MPa, the temperature is 95°C, the temperature at the botto...

Embodiment 2

[0028] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 6510 mg / L, the free ammonia is 2130 mg / L, the fixed ammonia is 1640 mg / L, and the CO 2 5054 mg / L, pH value is 8.4, water temperature is 78°C, flow rate is 47 t / h, press figure 1 Process shown.

[0029] The extraction tower adopts a packed tower, the feed ratio of backwater to wastewater is 1:3.4, the volume ratio of extractant butyl acetate to wastewater is 1:6, the temperature at the top of the deacidification tower is 33°C, the pressure is 0.35MPa, the temperature at the bottom of the tower is 100°C, and the pressure is 0.45 MPa, the reflux ratio is 1:3.5. The pressure at the top of the deamination tower is 0.45MPa, the temperature is 125°C, the pressure at the bottom of the tower is 1.1MPa, and the temperature is 150°C; the pressure at the top of the solvent recovery tower is 0.18MPa, the temperatur...

Embodiment 3

[0031] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 5520 mg / L, the free ammonia is 3310 mg / L, the fixed ammonia is 2620 mg / L, and the CO 2 5054 mg / L, pH value is 8.8, water temperature is 83°C, flow rate is 70 t / h, press figure 1 Process shown.

[0032] The extraction tower adopts a packed tower, the feed ratio of backwater to wastewater is 1:4.9, the volume ratio of extractant butyl acetate to wastewater is 1:5, the temperature at the top of the deacidification tower is 22°C, the pressure is 0.45MPa, the temperature at the bottom of the tower is 108°C, and the pressure is 0.55 MPa, the reflux ratio is 1:3.8. The pressure at the top of the deamination tower is 0.28MPa, the temperature is 130°C, the pressure at the bottom of the tower is 1.15MPa, and the temperature is 190°C; the pressure at the top of the solvent recovery tower is 0.11MPa, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com