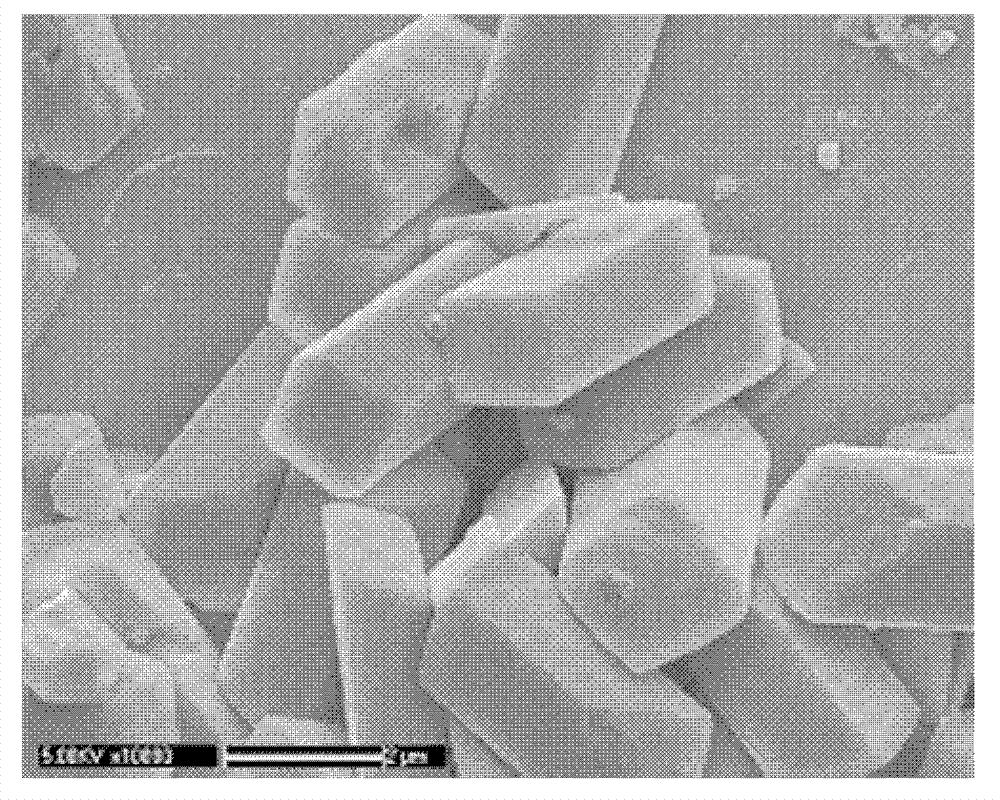

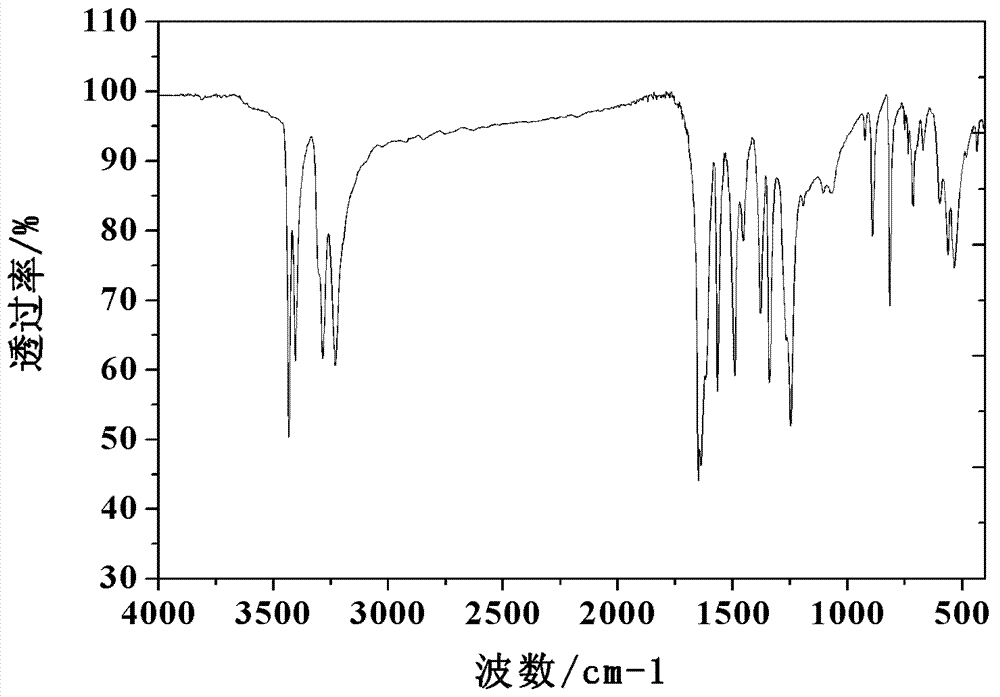

Preparation method of cubic short rod-shaped 1-oxo-diamino-3,5-dinitropyrazine explosive

A technology of dinitropyrazine explosives and short rods, which is applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., which can solve the problems of uneven forming powder columns, impact sensitivity, late formula processing, particle shape and Particle size influence, difficult binder and other problems, to achieve the effect of eliminating defects, improving subsequent processing and molding performance, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 5g LLM-105 and 150mL HNO with a mass percentage concentration of 30% respectively 3 , stir and heat up to 50°C to completely dissolve LLM-105, and filter to remove insoluble impurities to obtain LLM-105 / HNO 3 Explosive solution; LLM-105 / HNO 3 Put the explosive solution into the explosive injection kettle, tighten the explosive injection kettle cover, fill the explosive injection kettle with high-purity nitrogen with a purity of 99.5%, and keep the internal pressure of the explosive injection kettle at 1Mpa.

[0029] Weigh 1g of polyoxyethylene sorbitan monolaurate surfactant and add it to 300L ultrapure water, mix well, and configure LLM-105 explosive non-solvent; put LLM-105 explosive non-solvent into a low-temperature refrigerator, Pre-freeze at -10°C for 12 hours. Then the frozen LLM-105 explosive non-solvent is packed into the non-solvent storage tank, the cover of the non-solvent storage tank is tightened, and 99.5% high-purity nitrogen is charged into the n...

Embodiment 2

[0036]Take 5g LLM-105 and 100mL HNO with a mass percentage concentration of 45% respectively 3 , stir and heat up to 50°C to completely dissolve LLM-105, and filter to remove insoluble impurities to obtain LLM-105 / HNO 3 Explosive solution; LLM-105 / HNO 3 Put the explosive solution into the explosive injection kettle, tighten the explosive injection kettle cover, fill the explosive injection kettle with high-purity nitrogen with a purity of 99%, and keep the internal pressure of the explosive injection kettle at 0.5Mpa.

[0037] Weigh 2g of hexadecylamine bromide surfactant and add it to a mixture of 30L of ultrapure water and 500L of ammonia water with a concentration of 1% by mass, mix evenly to dissolve the cetylamine bromide, and configure it into LLM -105 explosive non-solvent; put LLM-105 explosive non-solvent in a low-temperature refrigerator, and pre-freeze at 0°C for 12 hours. Then put the frozen LLM-105 explosive non-solvent into the non-solvent storage tank, tighten...

Embodiment 3

[0043] Take 5g LLM-105 and 500mL HNO with a mass percentage concentration of 60% respectively 3 , stirred at room temperature to dissolve LLM-105 completely, and filtered to remove insoluble impurities to obtain LLM-105 / HNO 3 Explosive solution; LLM-105 / HNO 3 Put the explosive solution into the explosive injection kettle, tighten the explosive injection kettle cover, fill 99.7% high-purity nitrogen into the explosive injection kettle, and keep the internal pressure of the explosive injection kettle at 0.2Mpa.

[0044] Weigh 7g of OP-10 surfactant and add it to 30L ultrapure water, and weigh 300g of sodium hydroxide to make it into a solution of 5% sodium hydroxide by mass percentage, mix it evenly, and make it into LLM-105 explosive non-toxic Solvent; put the LLM-105 explosive non-solvent in a low-temperature refrigerator, and pre-freeze at -5°C for 12 hours. Then put the frozen LLM-105 explosive non-solvent into the non-solvent storage tank, tighten the cover of the non-sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com