Production method and device for ametryn

A production method and production device technology, applied in the field of ametryn production methods and devices, can solve the problems of long processing time, unstable product quality, high energy consumption, etc., reduce equipment investment, realize automatic control, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

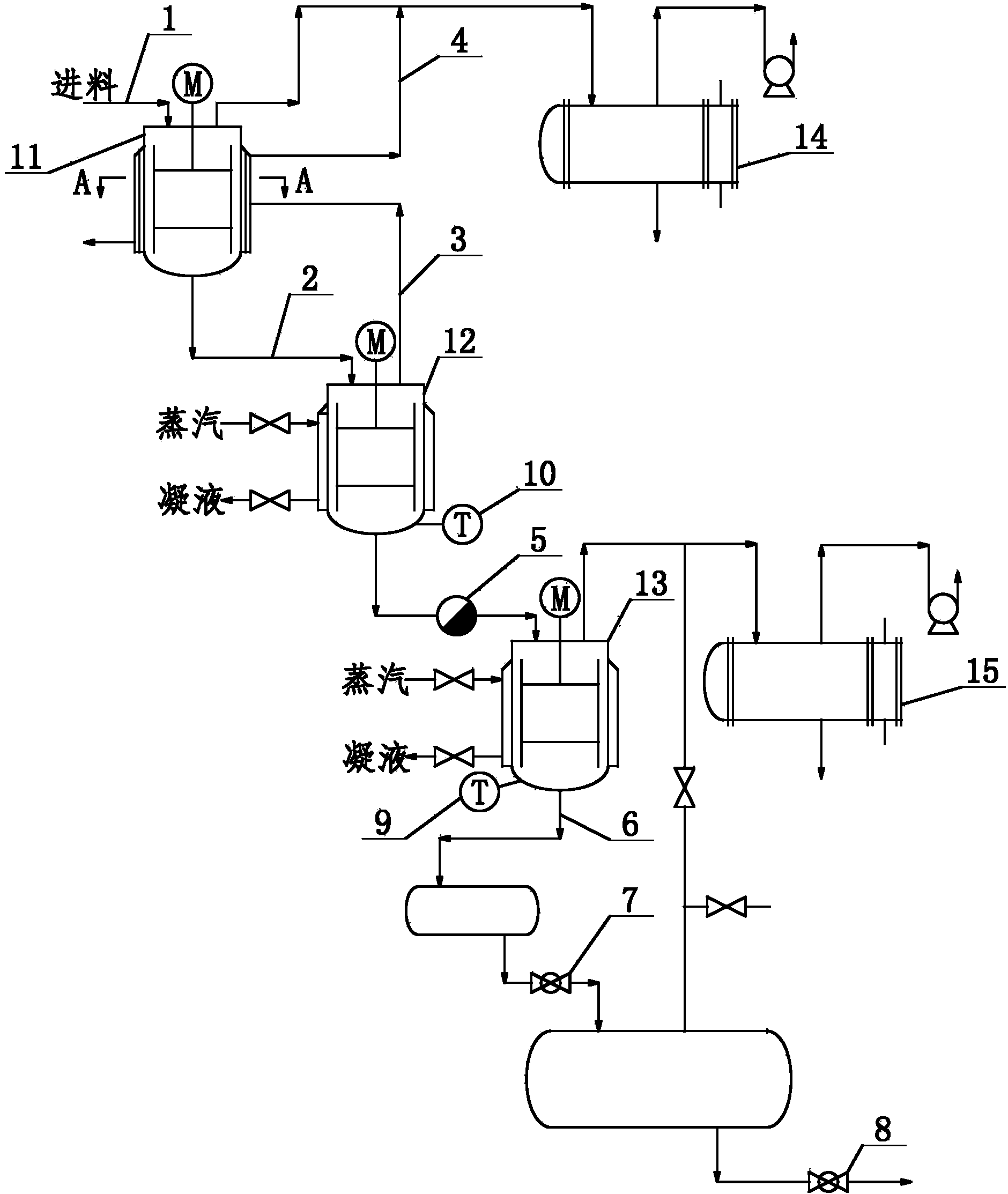

[0021] Such as figure 1 As shown, in the present invention, the scraper evaporator includes a first-stage scraper evaporator 11, a second-stage scraper evaporator 12, and a third-stage scraper evaporator 13 (the evaporation area is 10 square meters), and the first-stage scraper evaporator 11. The secondary scraped evaporator 12 and the tertiary scraped evaporator 13 are connected in series, arranged from top to bottom.

[0022] A material flow pipeline 2 is provided between the first-stage scraper evaporator 11 and the second-stage scraper evaporator 12, and the first-stage scraper jacket gas phase pipeline 4 is connected to the first-stage scraper evaporator 11, and the third-stage scraper evaporator 13 is connected with product transfer pipeline 6.

[0023] In order to reduce energy loss, equipment and pipelines are insulated.

[0024] Such as figure 2 As shown, the first-stage scraper evaporator is equipped with a special jacket, and the inside of the jacket is finned. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com