Novel humectant 3-o-hydroxyethyl-d-glucose for cigarettes and preparation method thereof

A humectant and glucose technology for tobacco, which is applied in the preparation of sugar derivatives, chemical instruments and methods, tobacco, etc., can solve the problems of easy solidification at low temperature, weak humectant binding ability, and no moisture-proof effect, etc., to achieve synthetic Reasonable effect of the route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

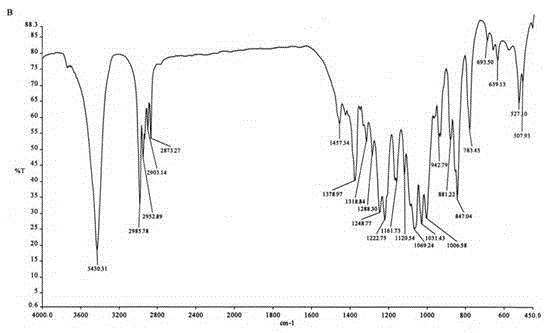

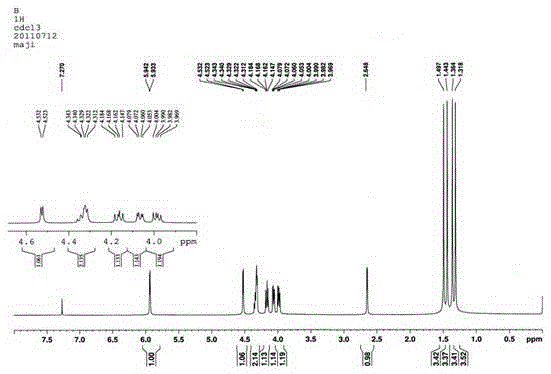

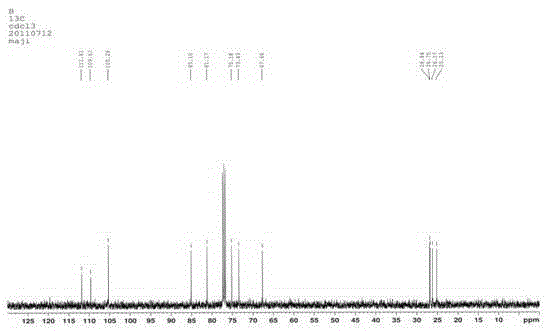

[0041] The preparation method of 3-O-hydroxyethyl-D-glucose, it comprises the steps:

[0042] (1) Preparation of 1,2:5,6-di-O-isopropylidene-α-D-glucofuranose (Ⅱ)

[0043] In a 500mL three-necked flask equipped with a magnetic stirring device, a thermometer and a reflux condenser, add 360mL of dried acetone, cool in an ice-water bath to lower the temperature of the solution to about 5°C, and slowly add 9mL of concentrated sulfuric acid into the acetone dropwise. During the dropwise addition process, keep the temperature below 10°C. Add 18 g of D-glucose to the solution, remove the ice-water bath to raise the temperature naturally, stir to completely dissolve the D-glucose, and then react with stirring at 15°C for 6 hours.

[0044] After cooling in an ice-water bath to lower the reaction solution below 5 °C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 7. Subsequently, the reaction solution was concentrated under reduce...

Embodiment 2

[0053] The preparation method of 3-O-hydroxyethyl-D-glucose, it comprises the steps:

[0054] (1) Preparation of 1,2:5,6-di-O-isopropylidene-α-D-glucofuranose (Ⅱ)

[0055] In a 1000mL three-necked flask equipped with a magnetic stirring device, a thermometer and a reflux condenser, add 540mL of dried acetone, cool in an ice-water bath to lower the solution temperature to about 5°C, and slowly add 18mL of concentrated sulfuric acid into the acetone dropwise. During the dropwise addition process, keep the temperature below 10°C. Add 18 g of D-glucose to the solution, remove the ice-water bath to raise the temperature naturally, stir to completely dissolve the D-glucose, and then react with stirring at 35°C for 10 h.

[0056] After cooling in an ice-water bath to lower the reaction solution below 5°C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 8. Subsequently, the reaction solution was concentrated under reduced press...

Embodiment 3

[0065] The preparation method of 3-O-hydroxyethyl-D-glucose, it comprises the steps:

[0066] (1) Preparation of 1,2:3,4-di-O-isopropylidene-α-D-fructopyranose (Ⅱ)

[0067] In a 1000mL three-necked flask equipped with a magnetic stirring device, a thermometer and a reflux condenser, add 450mL of dried acetone, cool in an ice-water bath to lower the solution temperature to about 5°C, and slowly add 12mL of concentrated sulfuric acid into the acetone dropwise. During the dropwise addition process, keep the temperature below 10°C. Add 18 g of D-glucose to the solution, remove the ice-water bath to raise the temperature naturally, stir to completely dissolve the D-glucose, and then react with stirring at 25°C for 8 hours.

[0068] After cooling in an ice-water bath to lower the reaction solution below 5 °C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 7.5. Subsequently, the reaction solution was concentrated under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com