Preparation method of water-lubricating rubber bearing

A rubber bearing and water lubrication technology, applied in the field of rubber bearings, can solve the problems of lack of performance data, and achieve the effect of good friction resistance and good seawater corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

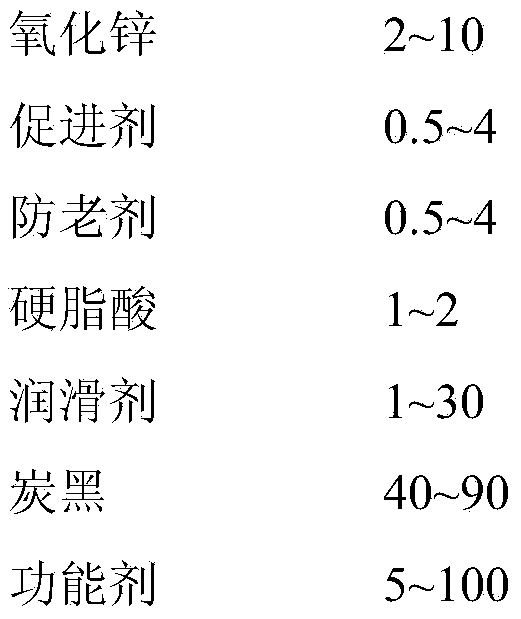

[0034] Compared with Comparative Example 1, the functional agent molybdenum disulfide was added to the formula, the addition amount was 10, 20, 30, and 50, and the addition amount of carbon black was 70. The formula is as follows:

[0035]

[0036] The molding and curing conditions were the same as those in Comparative Example 1.

Embodiment 2

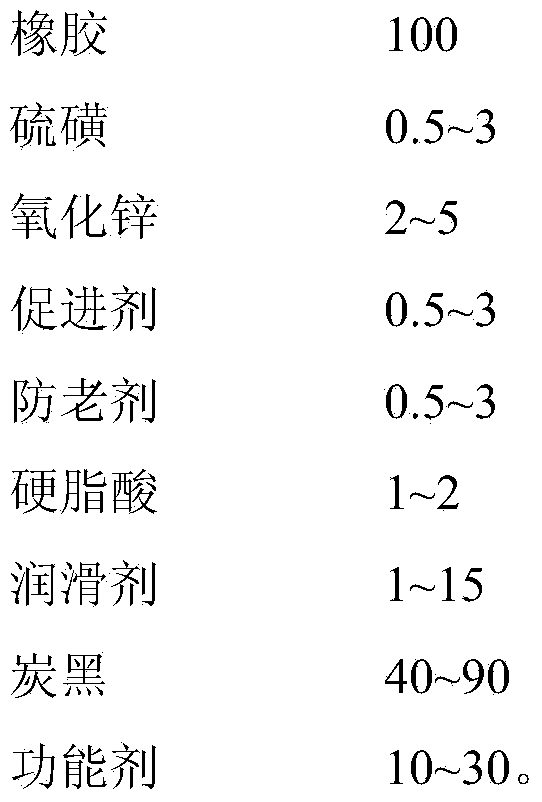

[0038] The rubber bearing was prepared according to the following composition and content mixture, where NBR JSR230 rubber with 35% CN content was used instead of NBR JSR240 with 26% CN content in Example 1. The addition amount of functional agent molybdenum disulfide was 10, and other components The formula is the same as in Example 1:

[0039]

[0040] The molding and curing conditions were the same as those in Comparative Example 1.

Embodiment 3

[0042] The rubber bearings prepared in Comparative Example 1 and Example 1 were combined with steel sets to form a bearing system. The friction coefficient and wear amount were tested on a marine rubber bearing friction tester. The test conditions were: speed 500r / min, load 500N , The time is 60min, fresh water is used as the lubricating medium, the measurement results are shown in Table 1 and Table 2.

[0043] Table 1. Results of friction coefficient and wear amount of rubber bearings prepared in Comparative Example 1

[0044]

[0045] Table 2. The friction coefficient and wear amount of the rubber bearing prepared in Example 1

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com