Bentonite grease composition and preparation method thereof

A technology of bentonite grease and composition, applied in the field of grease, can solve the problem that the low temperature performance needs to be further improved, and achieve the effect of good low temperature performance, favorable application, small starting torque and running torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the aforementioned bentonite grease composition, which includes the following steps:

[0042] a. Mix the additives with 1 / 2 mass of lubricating oil base oil, and obtain the first mixture after stirring;

[0043] b. Mix the organically modified bentonite, the structure improver, the first mixture with the remaining 1 / 2 mass of the lubricating base oil, and obtain a second mixture after stirring;

[0044] c. Grinding and vacuuming the second mixture to obtain a bentonite grease composition.

[0045] According to the above-mentioned mass percentage, the present invention first weighs 1 / 2 mass of lubricating oil base oil, adds additives, and stirs to obtain the first mixture. Wherein, the stirring is preferably performed using a star-shaped high-speed dispersing mixer; the stirring speed is preferably 1000rpm~4000rpm, more preferably 2000rpm~3000rpm; the stirring time is preferably 10min~50min, more preferably 20min~40min ...

Embodiment 1

[0062] Mix 40.75kg of lubricating base oil, 0.5kg of octyldiphenylamine, 2kg of calcium sulfonate rust inhibitor T104, 1kg of metal deactivator T551, and 2kg of calcium phosphate. Stir at a stirring speed of 2300rpm. After 10 minutes, the first mixture;

[0063] Reduce the stirring speed to 500rpm, slowly add 8kg of organically modified bentonite, and then stir at 2400rpm. After 20min, reduce the stirring speed to 300rpm, slowly add 5kg of 95% ethanol, and stir at 2500rpm for 25min Then reduce the stirring speed to 300 rpm, add 40.75 kg of lubricating base oil, stir at a stirring speed of 2400 rpm, and obtain the second mixture after 10 minutes;

[0064] Pass the second mixture through a three-roll mill, repeatedly grind it three times, and vacuumize it with a vacuum pump for 5 minutes to obtain the product bentonite grease composition.

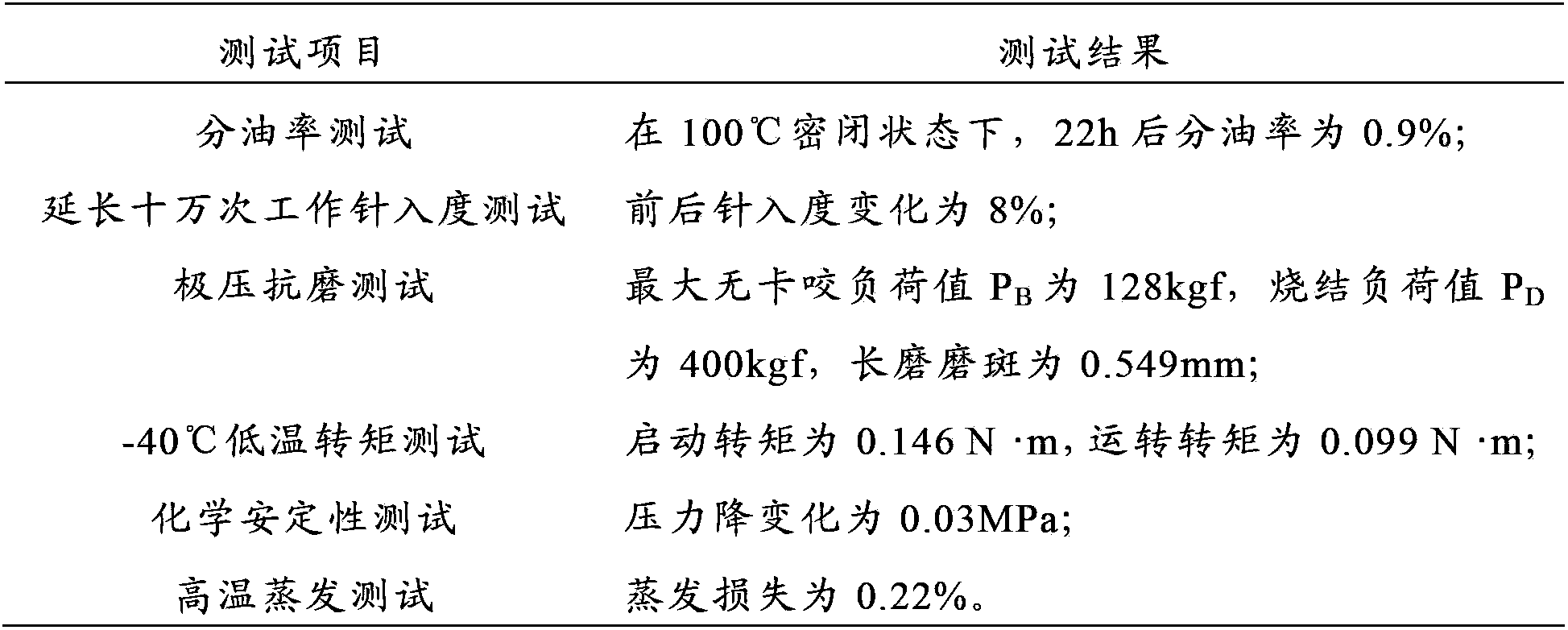

[0065] The performance test of the obtained bentonite grease composition was carried out according to the method described above, and the test res...

Embodiment 2

[0071] Mix 41.5kg of lubricating oil base oil, 0.5kg of octyldiphenylamine, 1kg of calcium sulfonate antirust agent T104, 1kg of metal deactivator T561 and 3kg of dialkyl antimony. Stir at a stirring speed of 2300rpm, and get it after 10min First mixture

[0072] Reduce the stirring speed to 500rpm, slowly add 8kg of organically modified bentonite, then stir at 2400rpm. After 20min, reduce the stirring speed to 300rpm, slowly add 4.5kg of 95% ethanol, and stir at 2500rpm. After 15 minutes, reduce the stirring speed to 300 rpm, add 41.5 kg of lubricating oil base oil, and stir at a stirring speed of 2400 rpm. After 10 minutes, the second mixture is obtained;

[0073] Pass the second mixture through a three-roll mill, repeatedly grind it three times, and vacuumize it with a vacuum pump for 5 minutes to obtain the product bentonite grease composition.

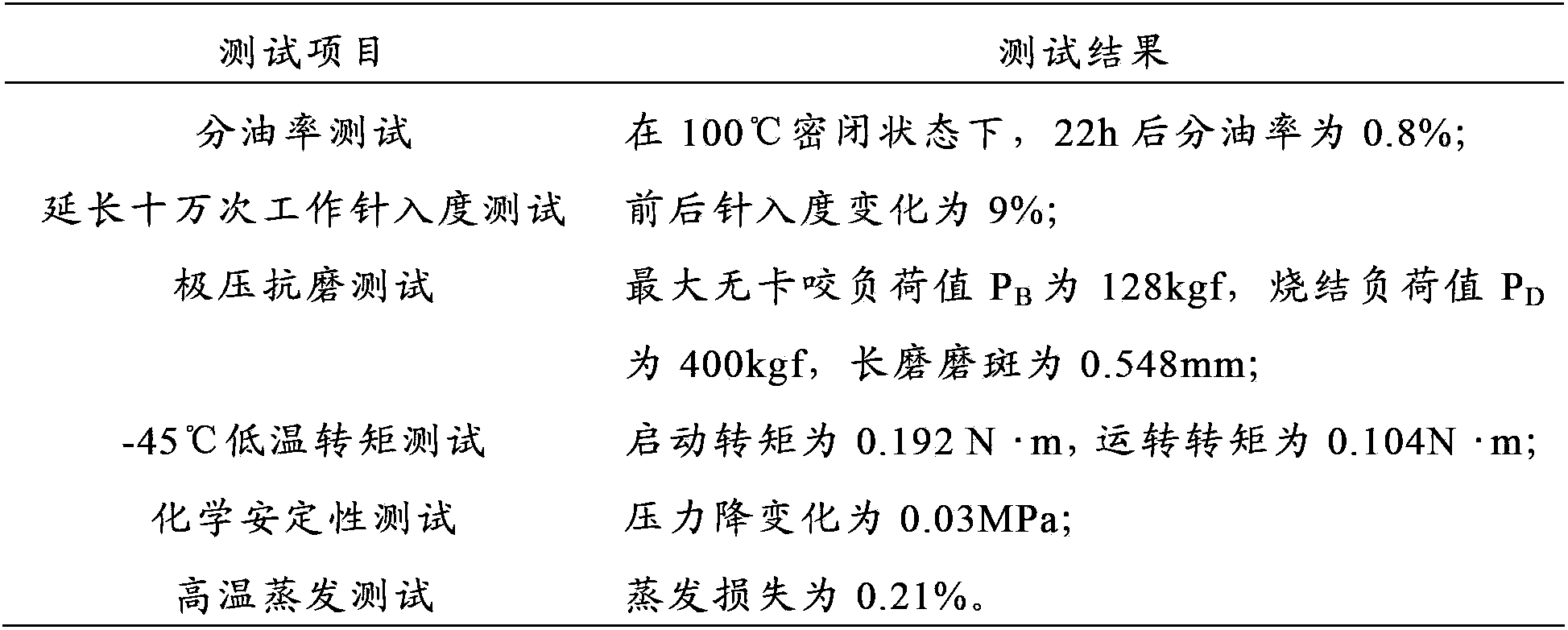

[0074] The performance test of the obtained bentonite grease composition was performed according to the method described above, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com