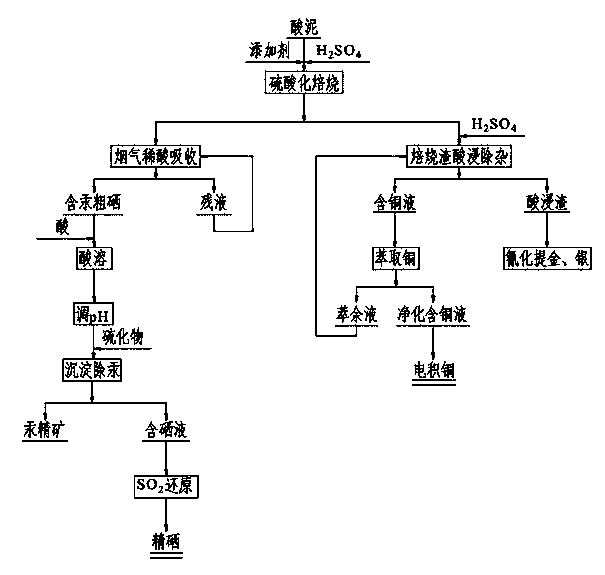

Method for recycling multiple elements in acid mud generated in acid making through gold smelting

A recovery method and multi-element technology, applied in the direction of element selenium/tellurium, improvement of process efficiency, etc., can solve the problems of ineffective recycling of selenium, low selenium content, affecting process indicators and gold and silver recovery rate, etc. Pollution problem, effect of high gold and silver recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1

[0018] The mass content of the main components contained in an acid mud is as follows: Au84g / t, Ag430g / t, Cu6.23%, Se7.97%, Hg11.83%, Fe18.36%, Pb1.73%, SiO 2 39.61%, Al 2 O 3 1.04%, CaO0.194%, MgO0.193%. Weigh 500g of this acid mud after drying and put it into a roasting plate, and evenly spread it into a slurry with 500g of sulfuric acid, put it into a closed muffle furnace that is warmed up to 650 ℃ in advance, and control the roasting at 650 ℃ by introducing air. The selenium was evaporated, and the roasting flue gas was collected by using a sulfuric acid solution with a mass fraction of 5% at 70°C under slight negative pressure, and the selenium and mercury were roasted and evaporated for 3 hours. After dilute acid filtration, a total of 98.06g of selenium-mercury mixture was obtained, 300ml of water was added, 600ml of nitric acid with a mass fraction of 40% was added in small amounts and multiple times, and the acid solution temperature was control...

Example Embodiment

[0020] Example 2

[0021] The mass content of the main components contained in an acid mud is as follows: Au4g / t, Ag1167g / t, Cu 0.5%, Se1.53%, Hg2.82%, Fe19.79%, Pb1.57%, SiO 2 23.18%, Al 2 O 3 2.15%, CaO0.257%, MgO0.212%. Weigh 667 g of this acid mud with a water content of 15% and put it into a roasting pan, mix in 0.4 g of sodium chloride, make it into a slurry with 250 g of sulfuric acid, and spread it evenly, and put it into a closed muffle furnace that is heated to 250 ° C in advance, The selenium was roasted and evaporated at 300°C by introducing air, and the roasting flue gas was collected by using a sulfuric acid solution with a mass fraction of 20% at 80°C under a slight negative pressure, and the selenium and mercury were roasted and evaporated for 8 hours. After dilute acid filtration, a total of 22.78g of selenium-mercury mixture was obtained, 100ml of water was added, 150ml of nitric acid with a mass fraction of 40% was added in small amounts and multiple tim...

Example Embodiment

[0023] Example 3

[0024] The mass content of the main components contained in an acid mud is as follows: Au 2g / t, Ag 14g / t, Cu 0.04%, Se48.14%, Hg5.90%, Fe0.704%, Pb2.53%, SiO 2 8.69%, Al 2 O 3 4.15%. The acid mud belongs to high selenium and mercury-containing ore, and the recoverable valuable elements are only selenium and mercury. Weigh 200g of this acid mud after drying and put it into a roasting pan, mix it with 300g of sulfuric acid and adjust it into a slurry and spread it evenly. Roasting and steaming selenium, the roasting flue gas was collected with a sulfuric acid solution with a mass fraction of 30% at 90°C under slight negative pressure, and the selenium and mercury were roasted and steamed for 1.5 h. After dilute acid filtration, a total of 111.0g of selenium-mercury mixture was obtained, 800ml of water was added, 1400ml of nitric acid with a mass fraction of 20% was added in small amounts and multiple times, and the acid solution temperature was controlled ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap