Single end LED energy-saving lamp and drive circuit thereof

A technology of LED energy-saving lamps and LED light sources, applied in the direction of lamp circuit layout, circuits, energy-saving control technology, etc., to achieve the effects of small irradiation area, increased heat dissipation area, and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

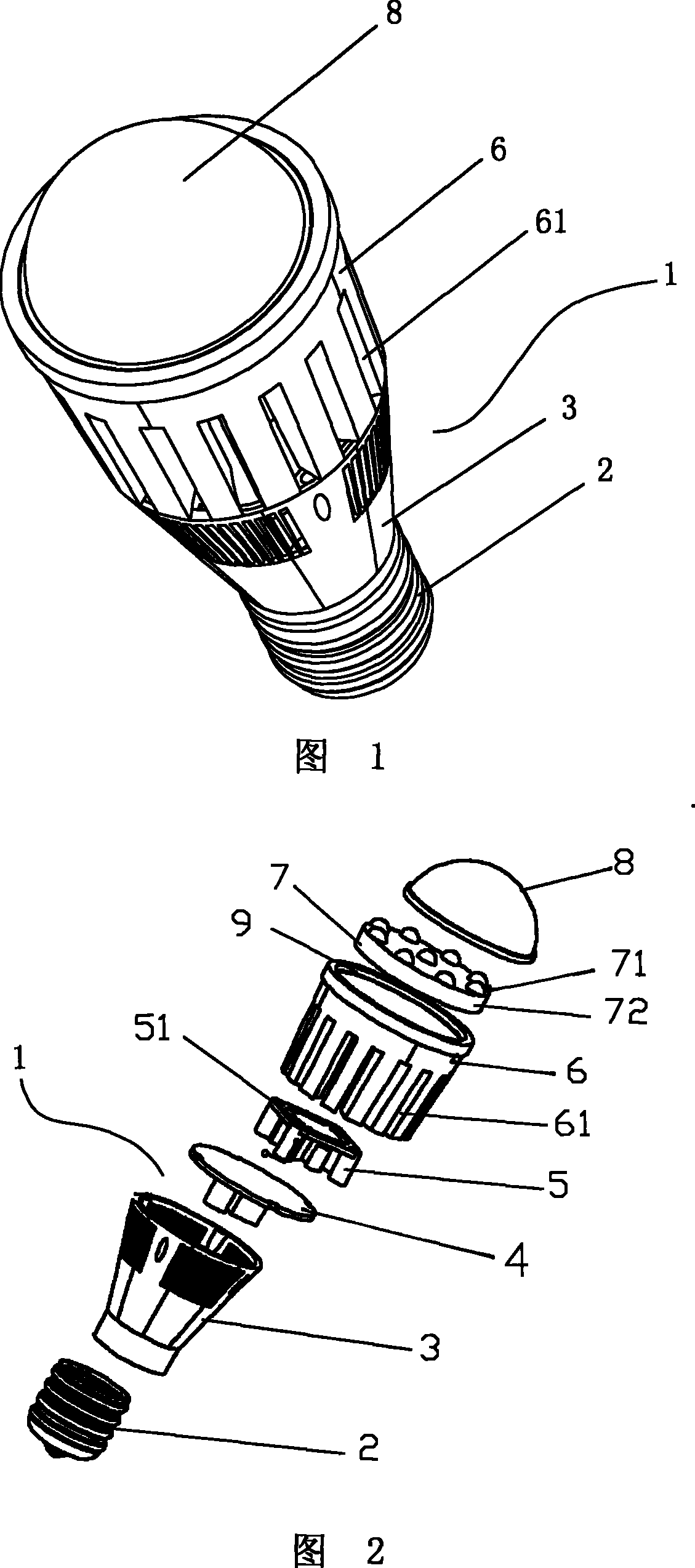

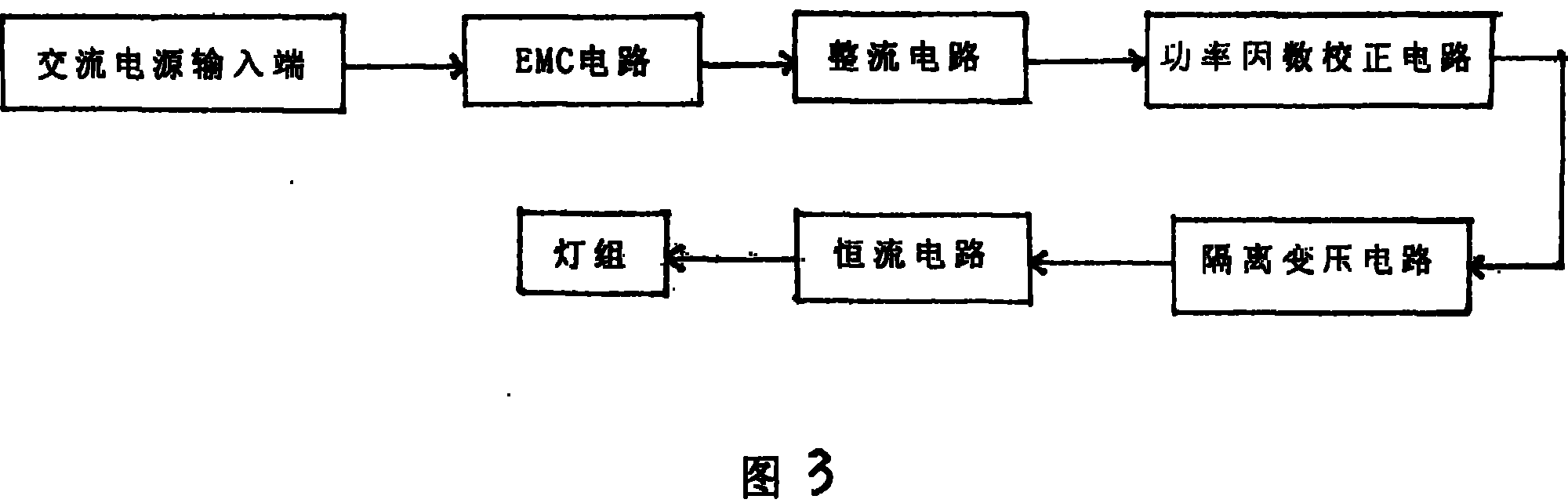

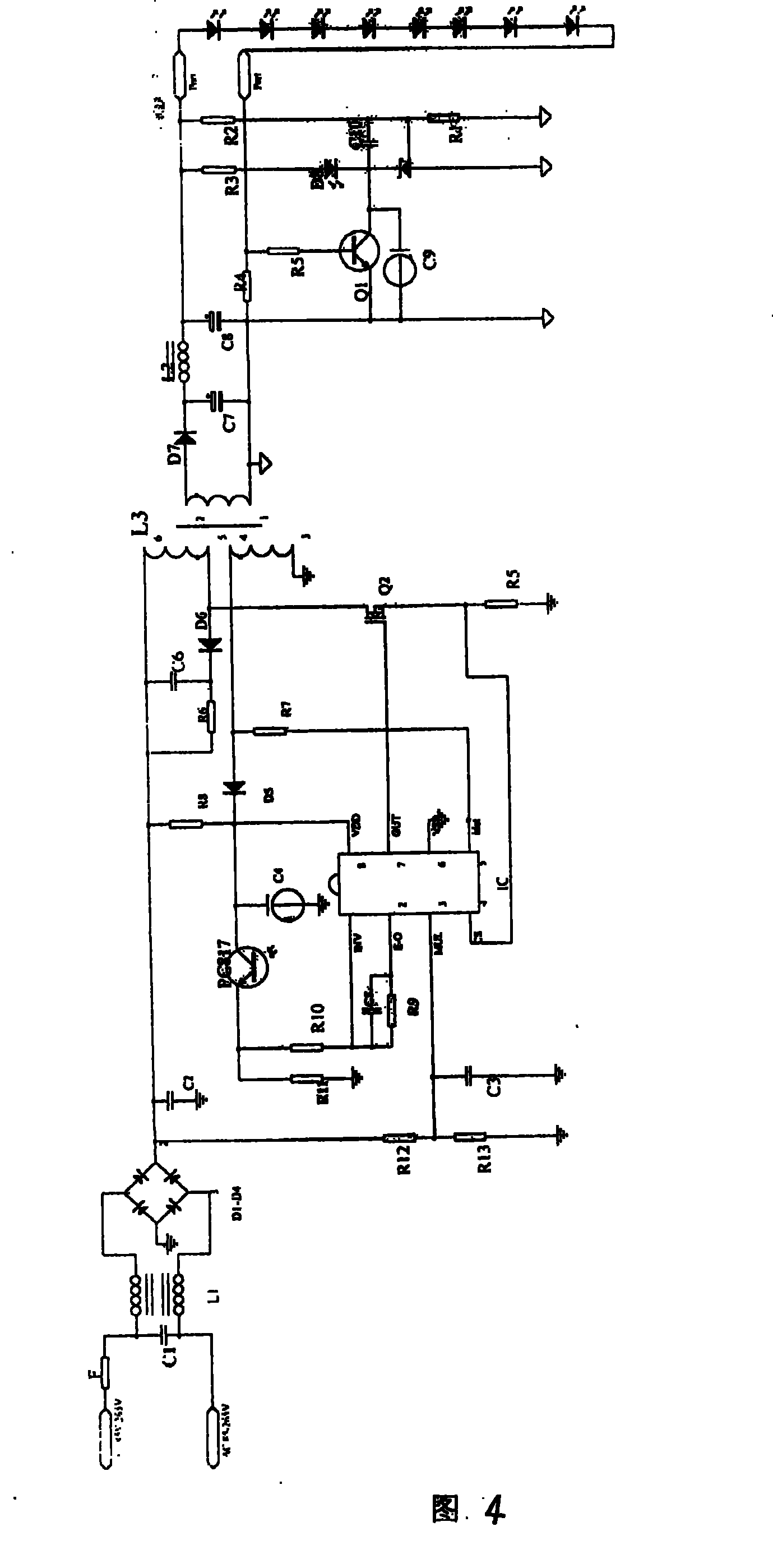

[0031] Embodiment 1: see Figure 1 ~ Figure 2 , a single-ended replacement LED energy-saving lamp 1 provided by the present invention, which includes a plurality of LED light sources, which is a cylindrical shape as a whole, and also includes a metal joint 2, a lamp holder 3, a Drive circuit board 4, a fan 5, a heat sink 6, an LED light board 7, a lens 8; the lamp holder 3 and the heat sink 6 are cylindrical metal components, and the metal joint 2 is arranged on the lamp holder 3, the drive circuit board 4 is provided with a drive circuit, which is set in the lamp holder 3, the fan 5 and LED light board 7 are set in the heat sink 6, and the lens 8 is set in the The front part of the heat sink 6; the electrodes of the metal joint 2, the drive circuit board 4, the fan 5 and the LED light board 7 are electrically connected to each other; it also includes a reflective lamp cup 9, which is an opening forward, and the inner wall is a reflective surface The trumpet-shaped member is ...

Embodiment 2

[0038] Example 2: see Figure 4 , Figure 5 , a kind of single-ended replacement LED energy-saving lamp and its drive circuit provided by the present invention, its basic structure is the same as that of Embodiment 1, the difference is that the metal used in the single-ended replacement LED energy-saving lamp 1 Connector 2 is a square connector used in conjunction with the PLC tube G24 interface, which includes a plug body 21 and two metal electrodes 22 arranged on the body 21, which can be directly plugged into the G24 interface; The lens 8 is a concave lens with an astigmatism effect, specifically a double-sided concave lens.

[0039] In other embodiments, the metal joint 2 can also be a variety of joints that are used with other lamp sockets such as E14, E40, etc.; the lens 8 can also be a flat mirror or other types Convex lens, concave lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com