Electrolyte for preparation of protective film for Zr alloy cladding and micro-arc oxidation process

A micro-arc oxidation, zirconium alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., to achieve good ionic conductivity and chemical stability, a wide range of solute sources, and improve corrosion resistance.

Inactive Publication Date: 2013-12-25

BEIJING NORMAL UNIVERSITY +2

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is still a lack of an electrolyte and micro-arc oxidation process for the preparation of zirconium alloy cladding protective film that can meet the use environment of nuclear reactor fuel rod cladding and the high temperature and high pressure corrosion protection requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

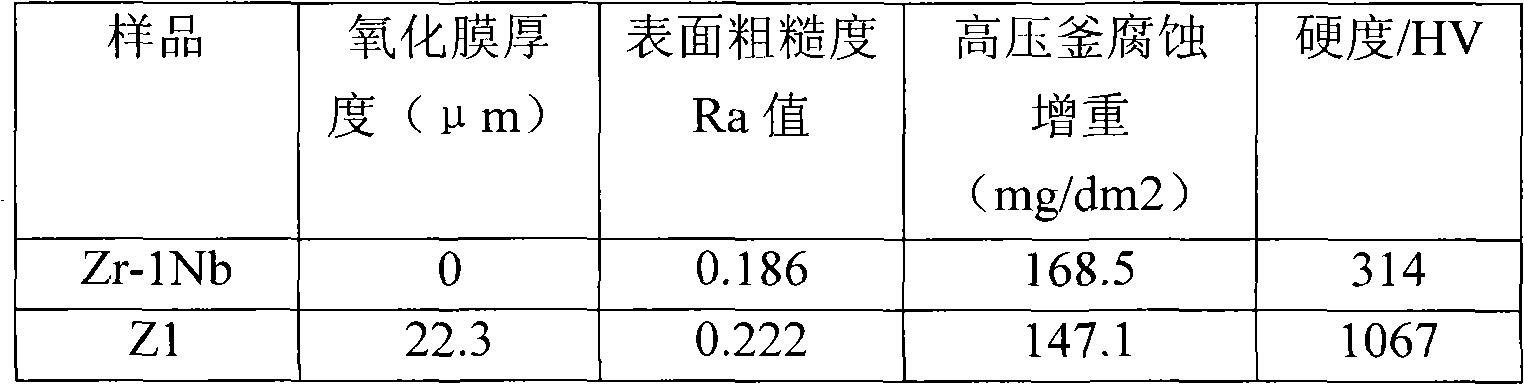

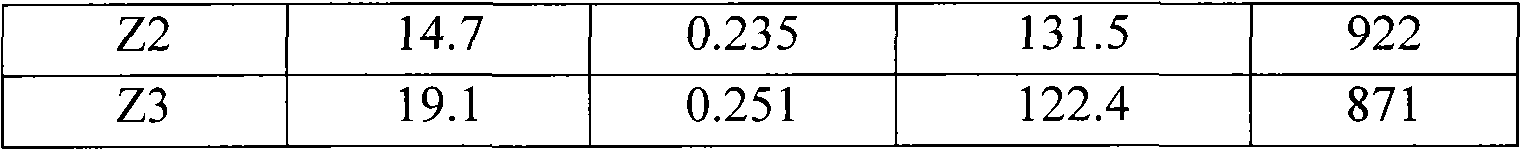

The invention discloses an electrolyte for micro-arc oxidation surface treatment of a Zr alloy cladding of a nuclear fuel rod. The electrolyte is a water solution containing rare earth salt, glycerin, sodium hydroxide and potassium hydroxide. The invention also discloses a preparation process of micro-arc oxidation film on surface of zirconium alloy cladding of the nuclear fuel rod, and the preparation process uses the electrolyte provided by the invention. Through the micro-arc technology provided by the invention, a layer of compact oxidation film is generated on the surface of a zirconium alloy cladding tube in advance, so as to corrosion resistance of the zirconium alloy cladding of the nuclear fuel rod in high temperature and high pressure water environment, and prolong the usage life of the nuclear fuel assemblies in a reactor.

Description

technical field [0001] The invention relates to an electrolyte and a process for preparing a protective film on the surface of nuclear fuel rod cladding by using micro-arc oxidation technology, which belongs to the field of zirconium alloy materials and material surface modification, and is mainly suitable for improving the temperature of nuclear fuel rod zirconium alloy cladding in high temperature and high pressure water. Corrosion resistance in the environment. Background technique [0002] Zirconium has a small thermal neutron absorption cross-section, good high-temperature water corrosion resistance and high-temperature mechanical properties, so zirconium alloys are widely used as cladding materials for nuclear fuel rods and structural components of reactor cores in nuclear power reactors. When zirconium alloy is used as the cladding of nuclear fuel, on the one hand, it is necessary to transfer the heat energy released during nuclear fuel fission to the coolant, and at ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D11/26

Inventor 薛文斌束国刚咸春宇王荣山邹志锋杜建成华铭施修龄刘彦章翁立奎贾兴娜

Owner BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com