Electrolyte and its use and method for preparing nuclear fuel rod zirconium alloy cladding micro-arc oxidation film

A micro-arc oxidation, nuclear fuel rod technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., to achieve the effects of improving corrosion resistance, wide solute sources, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

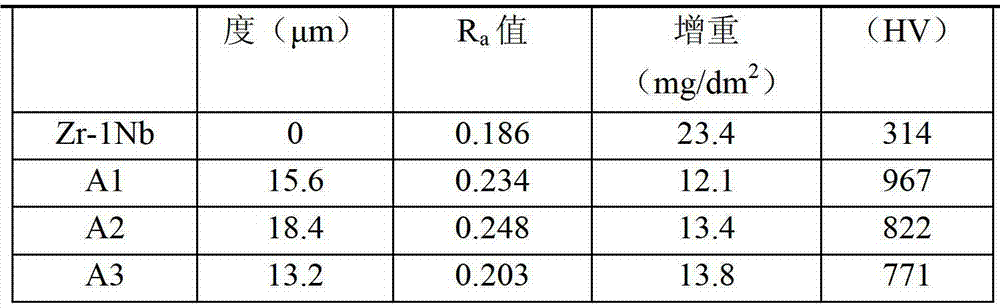

Embodiment 1

[0034] In this example, the treated zirconium alloy cladding material is a Zr-1Nb sample.

[0035] First, pre-treat the sample. The processing procedure is as follows: grind the surface of the sample with 200#, 400#, 600#, and 800# sandpaper; mechanically polish the polished sample, and use emery as the polishing agent; mechanically polish Chemical polishing is carried out after completion, and the reagent for chemical polishing is HNO 3 :HCl:H 2 O=4.5:4.5:1 (volume ratio) polishing solution, polishing time 10s; after chemical polishing is completed, use alcohol and ultrasonic cleaning, and finally, wash the surface of the sample with deionized water several times to remove the acid remaining on the surface . Put the chemically polished zirconium alloy into a vacuum furnace for thermal annealing treatment, the annealing temperature is 580° C., and the time is 2 hours.

[0036]Secondly: configure the electrolyte: the electrolyte is uniformly mixed with sodium carbonate, lith...

Embodiment 2

[0040] According to the same method as in Example 1, the Zr-1Nb sample is pretreated, the electrolyte is prepared, the zirconium alloy is subjected to micro-arc oxidation treatment, and finally the hole sealing treatment is performed. The difference is that in this example, the content of sodium carbonate in the electrolyte is 10g / L, the content of lithium hydroxide is 5g / L, and the content of glycerin is 30ml / L. The micro-arc oxidation treatment was carried out for 15 minutes under the condition that the forward voltage was 500V and the negative voltage was 60V.

[0041] Through the above steps, a zirconium alloy workpiece whose surface is covered with a layer of uniform and smooth micro-arc oxidation film is finally obtained, denoted as A2.

Embodiment 3

[0043] According to the same method as in Example 1, the Zr-1Nb is pretreated, the electrolyte is prepared, the surface of the zirconium alloy is subjected to micro-arc oxidation treatment, and finally the hole sealing treatment is performed. The difference is that in this example, the content of sodium carbonate in the electrolyte is 6g / L, the content of lithium hydroxide is 7g / L, and the content of glycerin is 50ml / L. The forward voltage of micro-arc oxidation treatment was 400V, and the negative voltage was 50V, and the treatment was carried out under these conditions for 15 minutes.

[0044] Through the above steps, a zirconium alloy workpiece whose surface is covered with a layer of uniform and smooth micro-arc oxidation film is finally obtained, denoted as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com