Reticular dimensional reinforced composite heat preservation rock wool board

A technology for enhancing composite and rock wool boards, which is applied in the directions of heat preservation, building components, fire prevention, etc., can solve the problems of complex production process of composite boards, inability to closely combine rock wool and steel plates, and unfavorable market popularization and promotion, and achieve excellent practical promotion. Use value, improve tensile strength and wind compressive strength, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

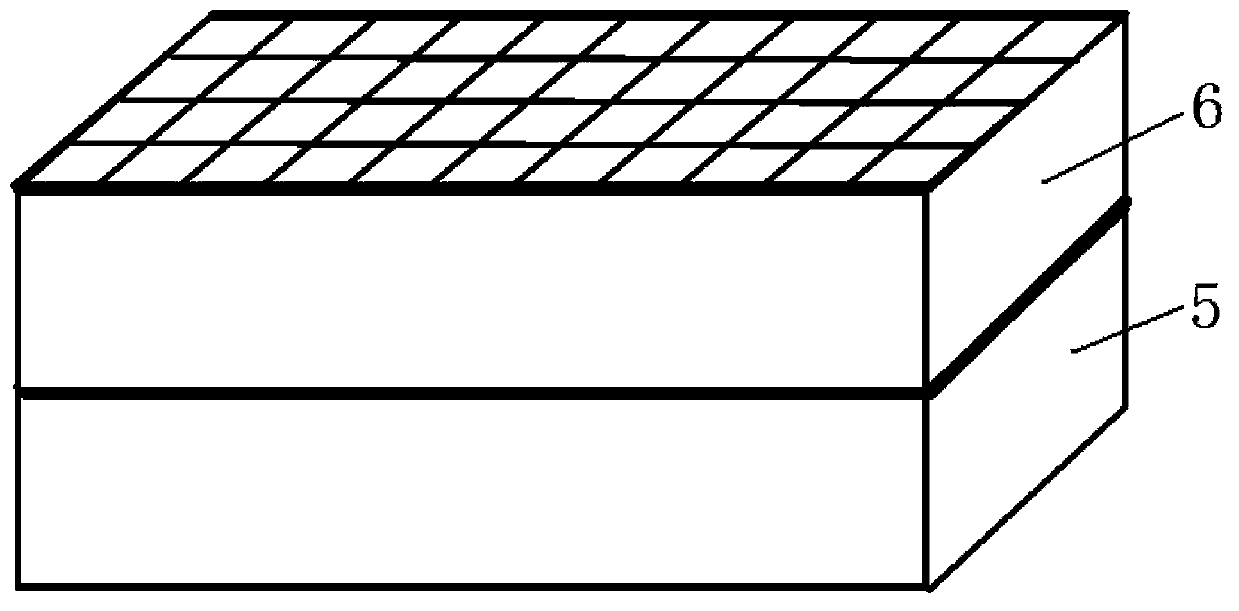

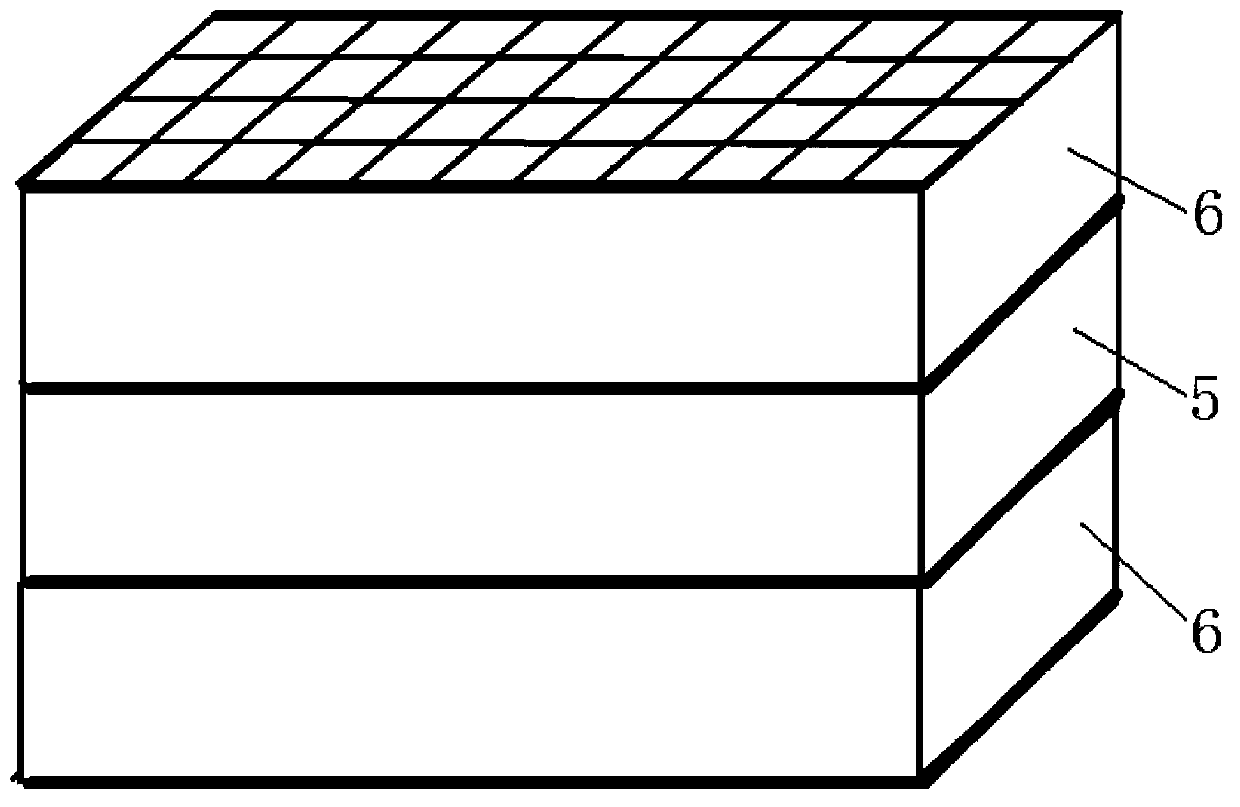

[0036] This embodiment relates to a network-dimensional reinforced single-composite thermal insulation rock wool board, and its structural diagram is as follows figure 1 shown by figure 1 It can be seen that the network dimension reinforced rock wool insulation board 6 and the organic insulation board 5 comprising 3 cm, the organic insulation board is a polyester board of 5 cm, and it is bonded with the network dimension reinforced rock wool insulation board 6 by direct foaming; Glue can be used. When used for buildings in cold areas with higher thermal insulation requirements, as a preferred solution of this embodiment, such as figure 2 The network-dimensional reinforced double-composite thermal insulation rock wool board is shown.

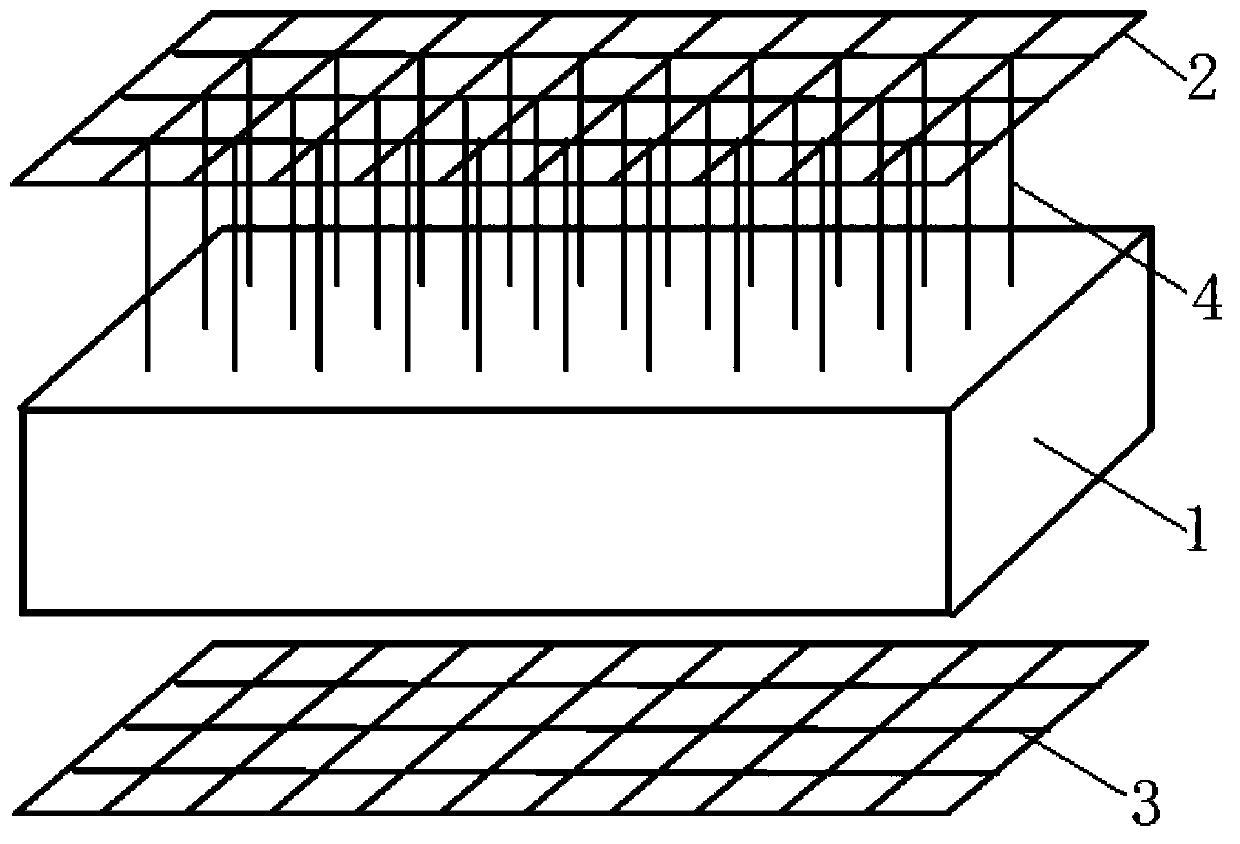

[0037] The net-dimensional reinforced rock wool thermal insulation board 6 in the net-dimensional reinforced single-composite thermal insulation rock wool board of the present embodiment is as follows: image 3 As shown, the rock wool layer 1...

Embodiment 2

[0041] This embodiment relates to a network-dimensional reinforced single-composite thermal insulation rock wool board, and its structural diagram is as follows figure 1 shown by figure 1 It can be seen that the network dimension reinforced rock wool insulation board 6 and the organic insulation board 5 comprising 3 cm, the organic insulation board is a polyester board of 5 cm, and it is bonded with the network dimension reinforced rock wool insulation board 6 by direct foaming; Glue can be used. When used for buildings in cold areas with higher thermal insulation requirements, as a preferred solution of this embodiment, such as figure 2 The network-dimensional reinforced double-composite thermal insulation rock wool board is shown.

[0042] The net-dimensional reinforced rock wool thermal insulation board 6 in the net-dimensional reinforced single-composite thermal insulation rock wool board of the present embodiment is as follows: Figure 4 As shown, the rock wool layer ...

Embodiment 3

[0046] This embodiment relates to a network-dimensional reinforced single-composite thermal insulation rock wool board, and its structural diagram is as follows figure 1 shown by figure 1 It can be seen that the network dimension reinforced rock wool insulation board 6 and the organic insulation board 5 comprising 3 cm, the organic insulation board is a polyester board of 5 cm, and it is bonded with the network dimension reinforced rock wool insulation board 6 by direct foaming; Glue can be used. When used for buildings in cold areas with higher thermal insulation requirements, as a preferred solution of this embodiment, such as figure 2 The network-dimensional reinforced double-composite thermal insulation rock wool board is shown.

[0047] The net-dimensional reinforced rock wool thermal insulation board 6 in the net-dimensional reinforced single-composite thermal insulation rock wool board of the present embodiment is as follows: Figure 5 As shown, the rock wool layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com