Fiber grating vibrating sensor with temperature insensitivity, tunable damping and high precision

A vibration sensor, fiber grating technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems affecting the popularization of sensors, and achieve the effect of improving signal measurement accuracy, stable sensing performance, and good prospects for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

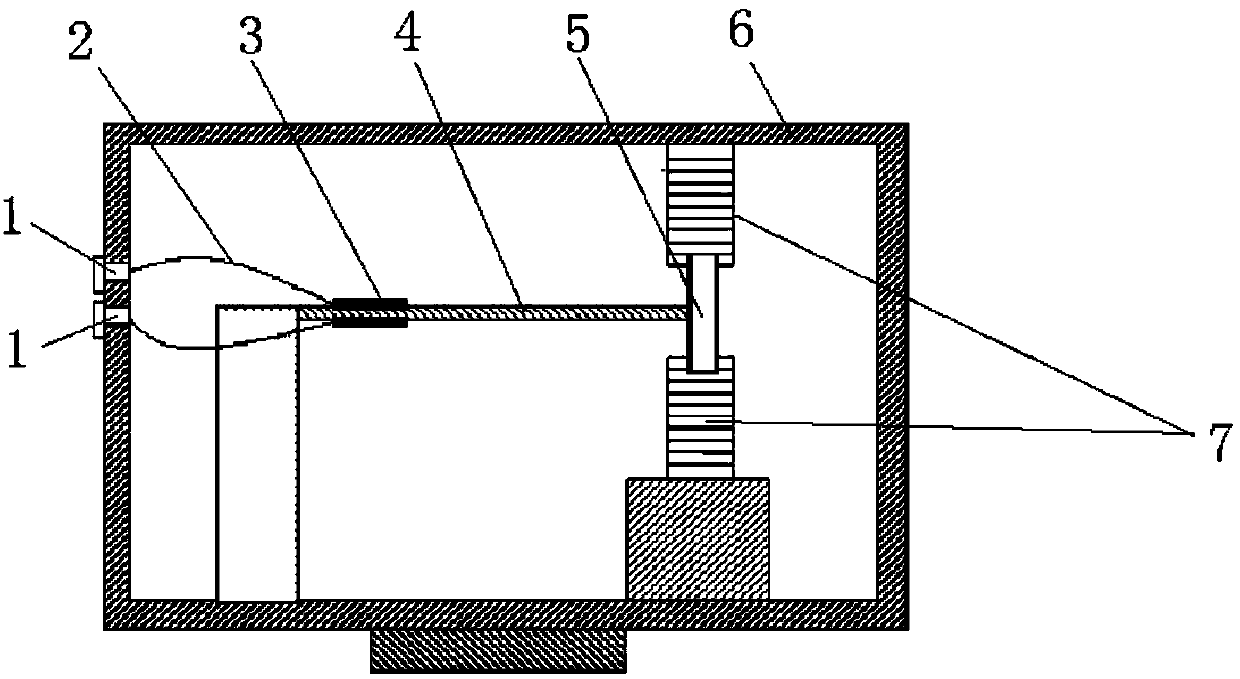

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

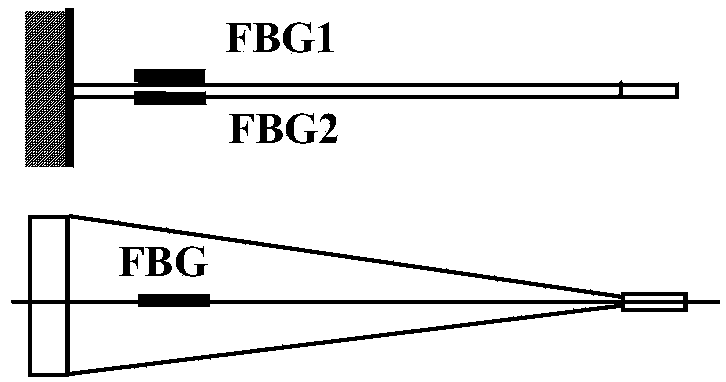

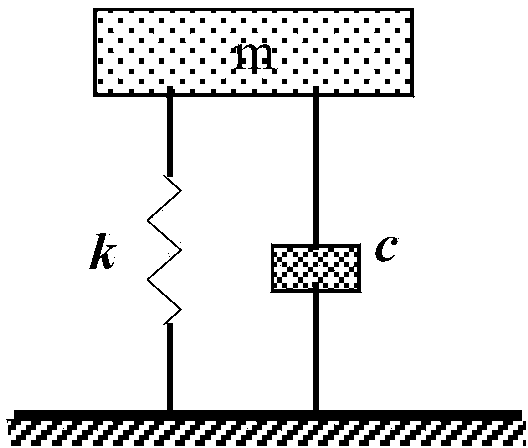

[0034] 1. The analysis of fiber grating sensing principle is as follows:

[0035] Fiber Bragg grating is a structure that uses the photosensitive properties of optical fiber materials to form a periodically changing refractive index on the core of the optical fiber through ultraviolet irradiation technology. The change of the refractive index of the fiber grating changes the waveguide condition of the fiber. According to the waveguide theory of the fiber grating, when the broadband light wave is transmitted in the sensing grating (FBG), the incident light undergoes mode coupling in the grating area, and the light of a specific wavelength is reflected back , the rest of the light is unaffected and transmitted through the fiber grating, so that the fiber grating actually acts as a wavelength selector for light reflection. When the temperature or stress of the environment around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com