Sampling and collecting system of SO3 in wet method desulphurization system tail flue gas

A collection system, wet desulfurization technology, applied in sampling devices, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the problems of large measurement errors, undiscovered, and instrument corrosion And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

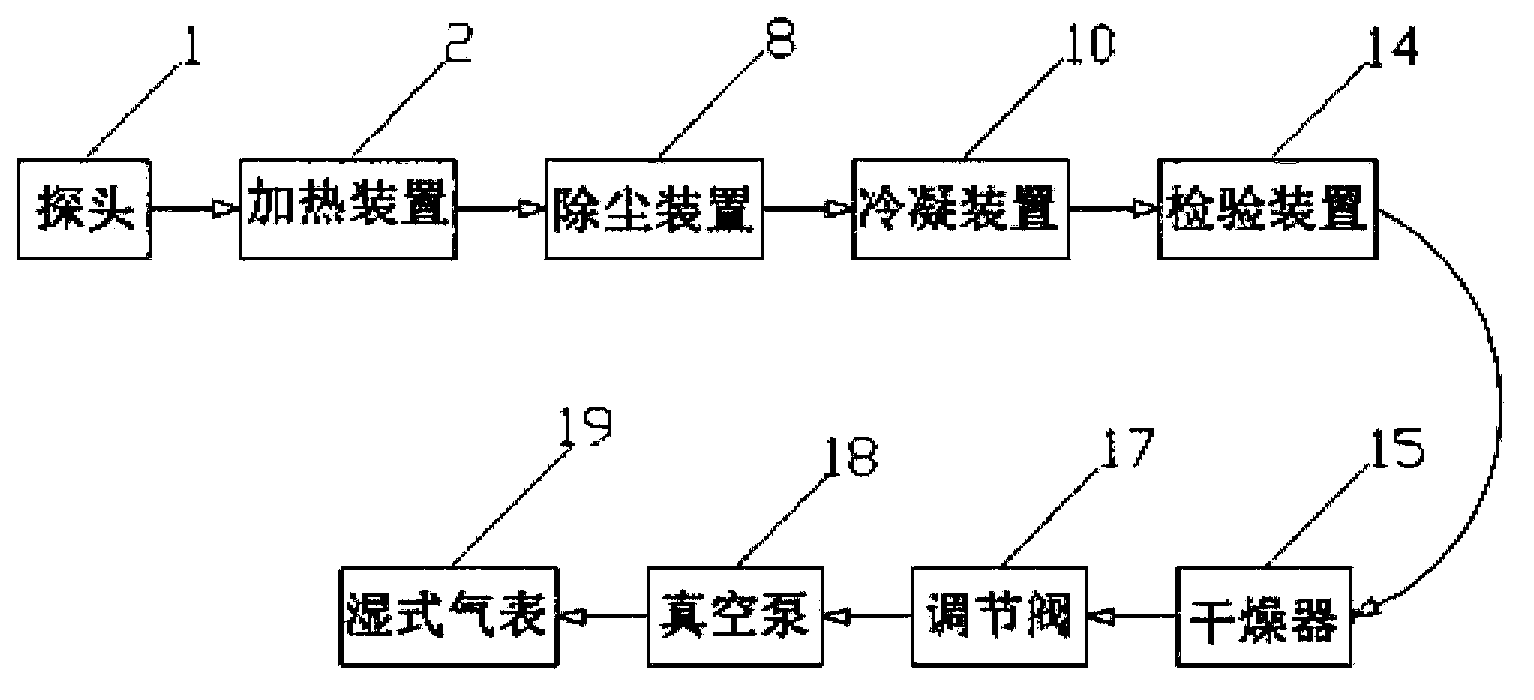

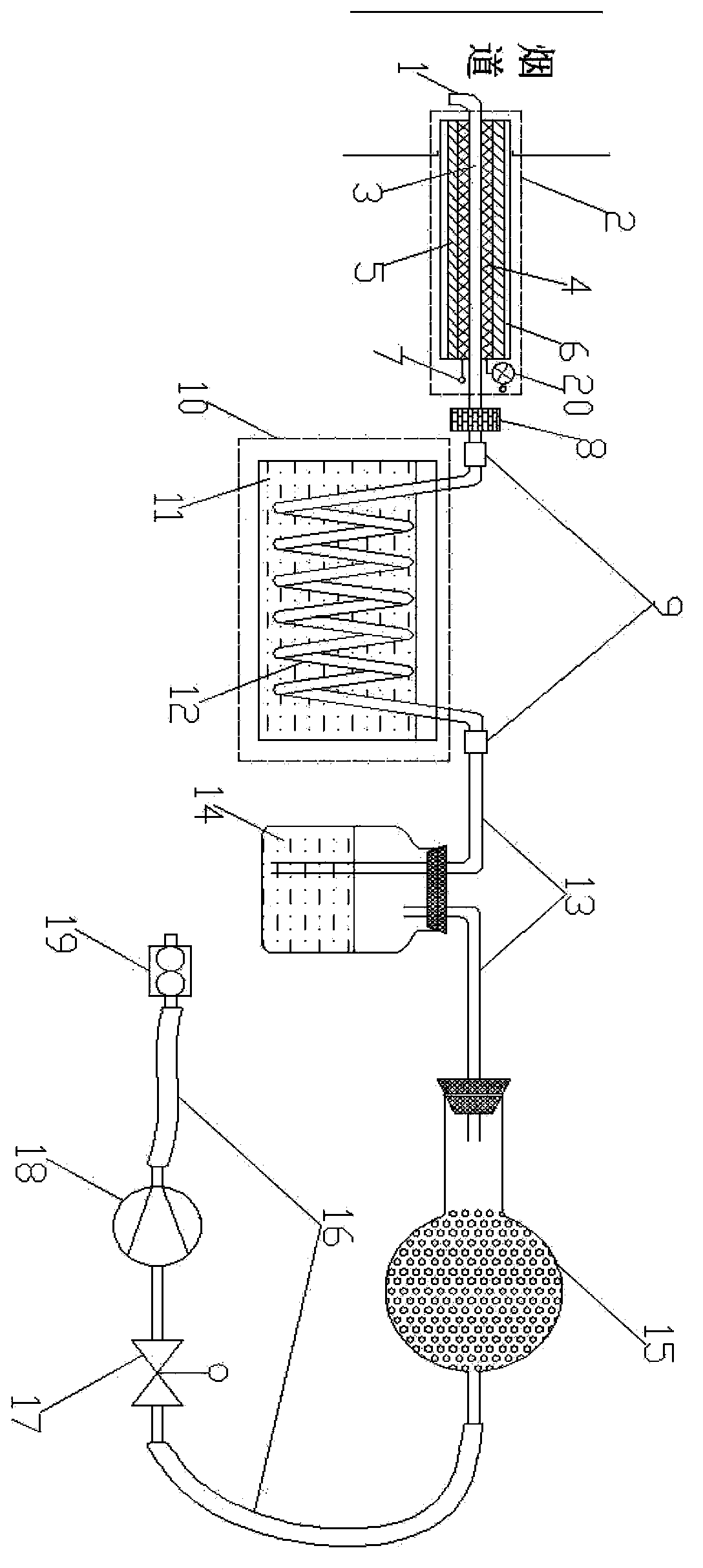

[0019] figure 1 It is a structural block diagram of the sampling collection system of the present invention; figure 2 It is a schematic structural diagram of the sample collection system in the embodiment of the present invention, which includes: probe 1, heating device 2, dust removal device 8, silicone tube 9, condensation device 10, glass tube 13, inspection device 14, dryer 15, rubber Pipe 16, regulating valve 17, vacuum pump 18, wet gas meter 19; wherein, heating device 2 includes inner pipe 3, constant temperature electric heating layer 4, insulation layer 5, outer pipe 6, power connector 7 and temperature controller 20; condensing device 10 It includes a constant temperature water tank 11 and a spiral condenser tube 12 .

[0020] The connection relationship of the above components is as follows:

[0021] The probe 1 is directly connected to the inlet of the heating device 2 (that is, the inlet of the inner pipe 3). The layer 4 is directly connected with the power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com