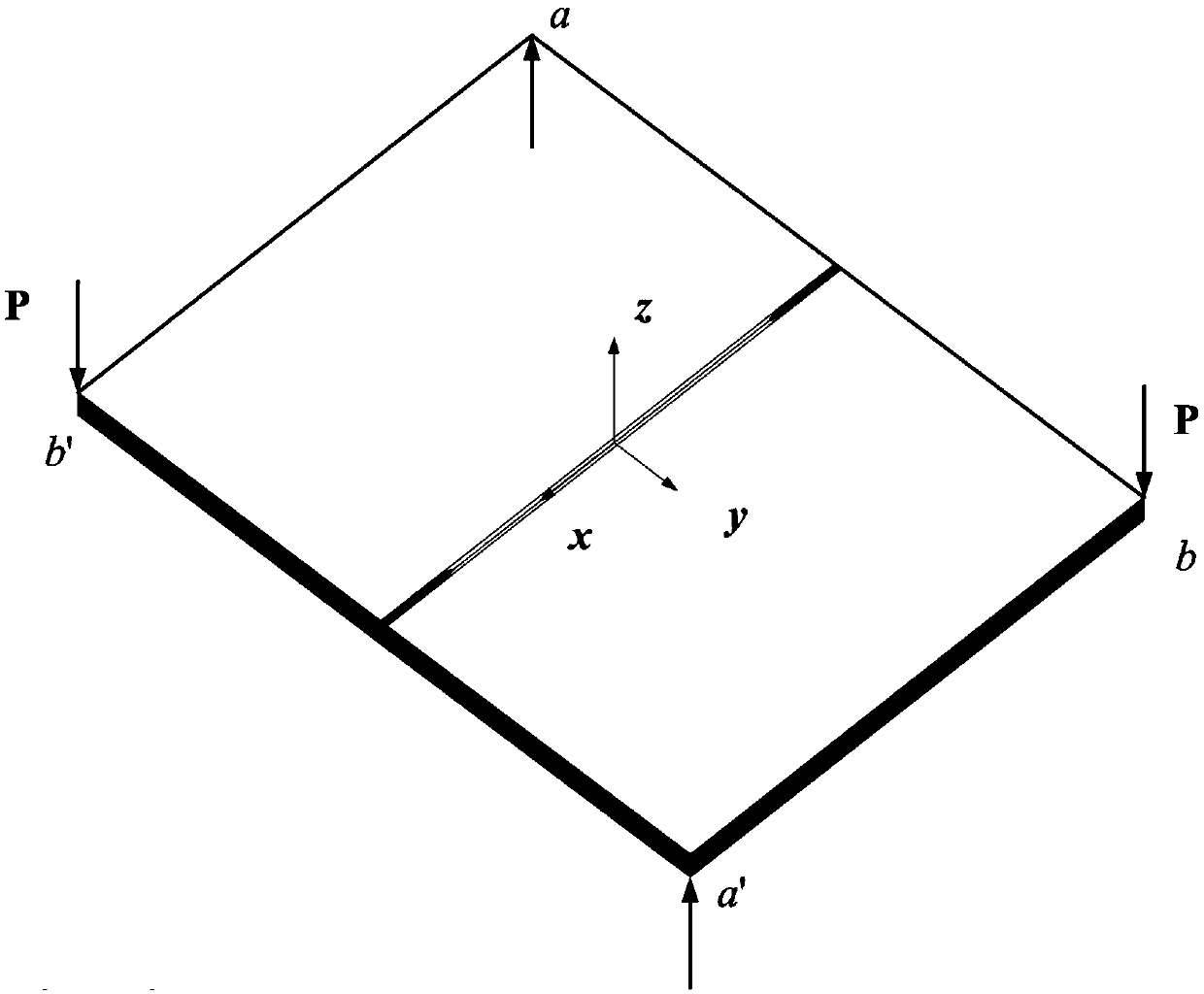

Test piece for fracture toughness of III type cracks

A technology of fracture toughness and test pieces, which is applied in the field of testing the basic mechanical properties of solid mechanics, can solve the problems of unfavorable symmetrical loading, low experimental success rate, and many loading points, etc., and achieve less experimental expenses, simple experiments, and easy operation and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The test piece of fracture toughness of type III crack of the present invention is applied to the measurement of fracture toughness of type III crack of double-base propellant, and the test piece of fracture toughness of flat type III crack of double-base propellant is produced. In order to ensure the validity of the test, according to the description of the claims in the present invention, the test piece is 100mm long and 80mm wide. Due to the low material density and relatively high stiffness, the thickness can be taken as 8mm, and the initial crack length is taken as 10mm. Because the modulus of the double-base propellant is small and the toughness is small, the depth of the V-shaped groove is taken as 1mm. Practice has proved that the invention of the test specimen for the fracture toughness of the mode III crack can be well applied to the measurement of the fracture toughness of the mode III crack of the double-base propellant. Shear strain.

Embodiment 2

[0031] The test specimen of the mode III crack fracture toughness of the present invention is applied to the measurement of the fracture toughness of the mode III crack of No. 45 steel, and the test specimen of the flat mode III crack fracture toughness of the No. 45 steel is produced. In order to ensure the validity of the test, according to the description of the claims in the present invention, the test piece is 100mm long and 80mm wide. Due to the high density of steel, the test results are easily affected by the weight of the material, so the thickness of the test piece is 8mm, and the initial crack length is 10mm. Because the modulus and toughness of the steel are large, the depth of the V-shaped groove is 2mm. Practice has proved that the invention of the test specimen for the fracture toughness of the mode III crack can be well applied to the measurement of the fracture toughness of the mode III crack of No. 45 steel. strain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com