System and method for supplying materials for mixed assembling production line based on RFID

A hybrid assembly and supply system technology, applied in manufacturing computing systems, logistics, induction record carriers, etc., can solve the problems of relying on manual operations, affecting the efficiency and accuracy of material supply, and low collection efficiency, reducing labor costs and reducing labor costs. Human error, coping with frequent changes in production status, and reducing the effect of worker's operational burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of the technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

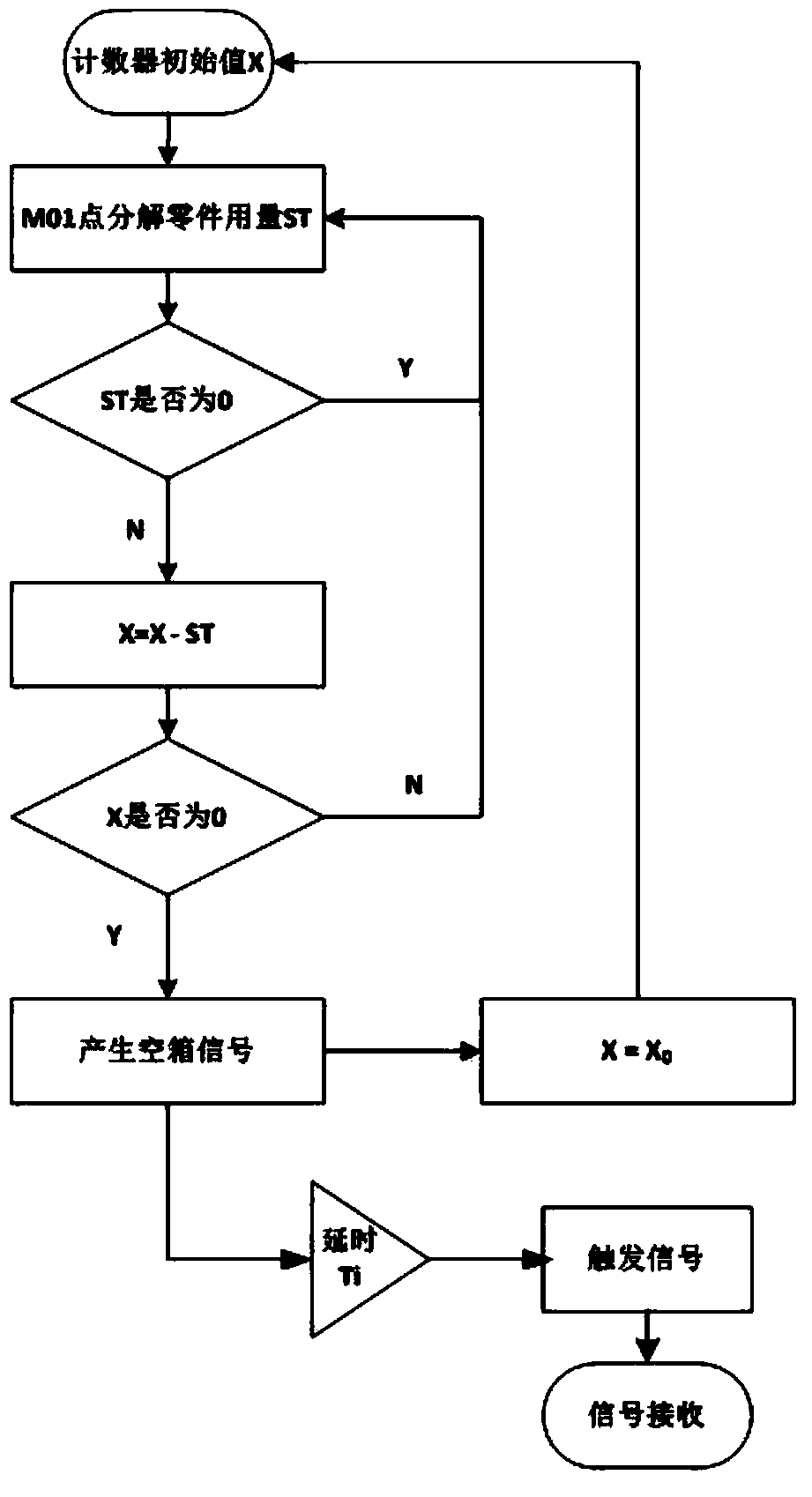

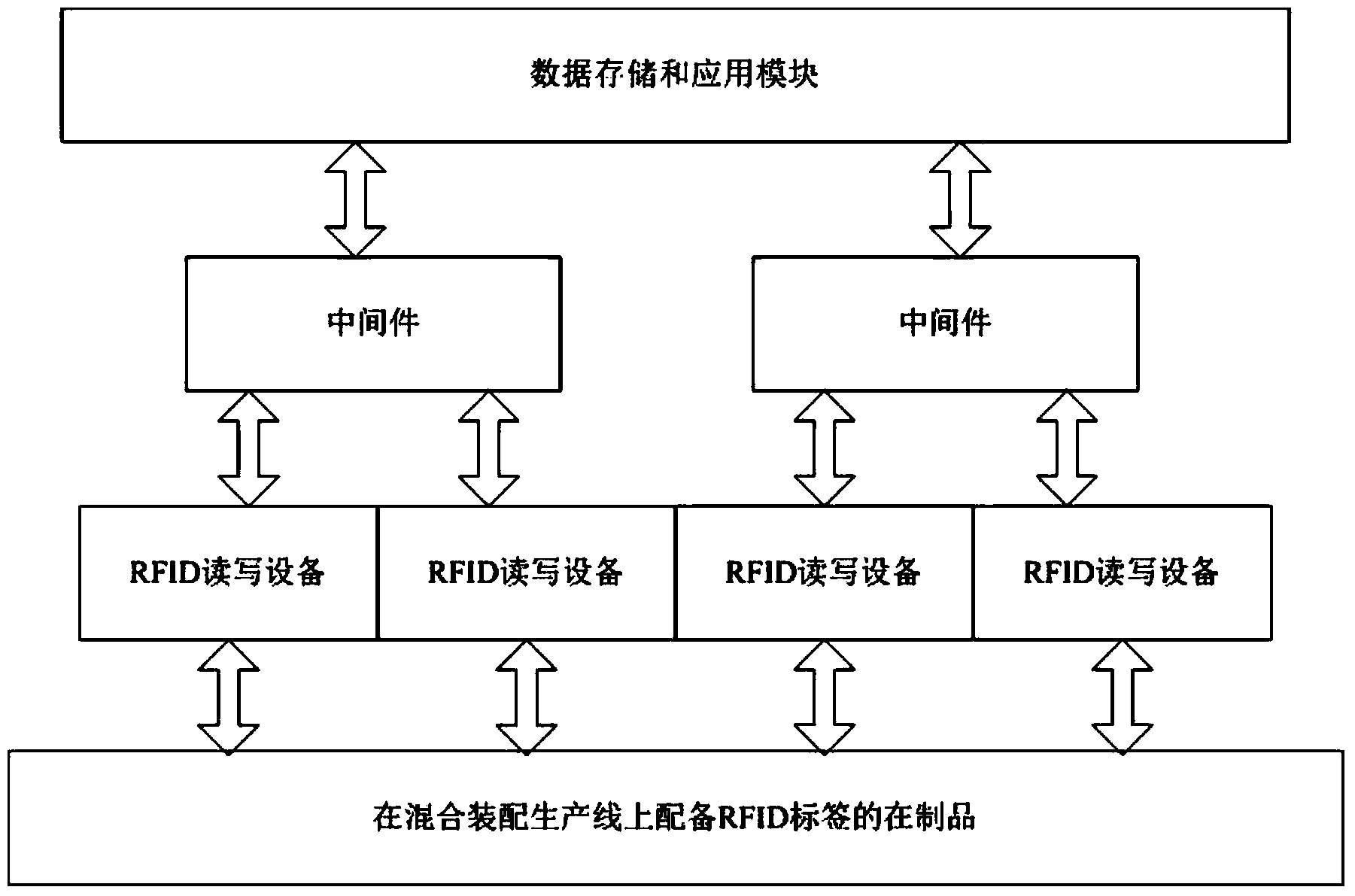

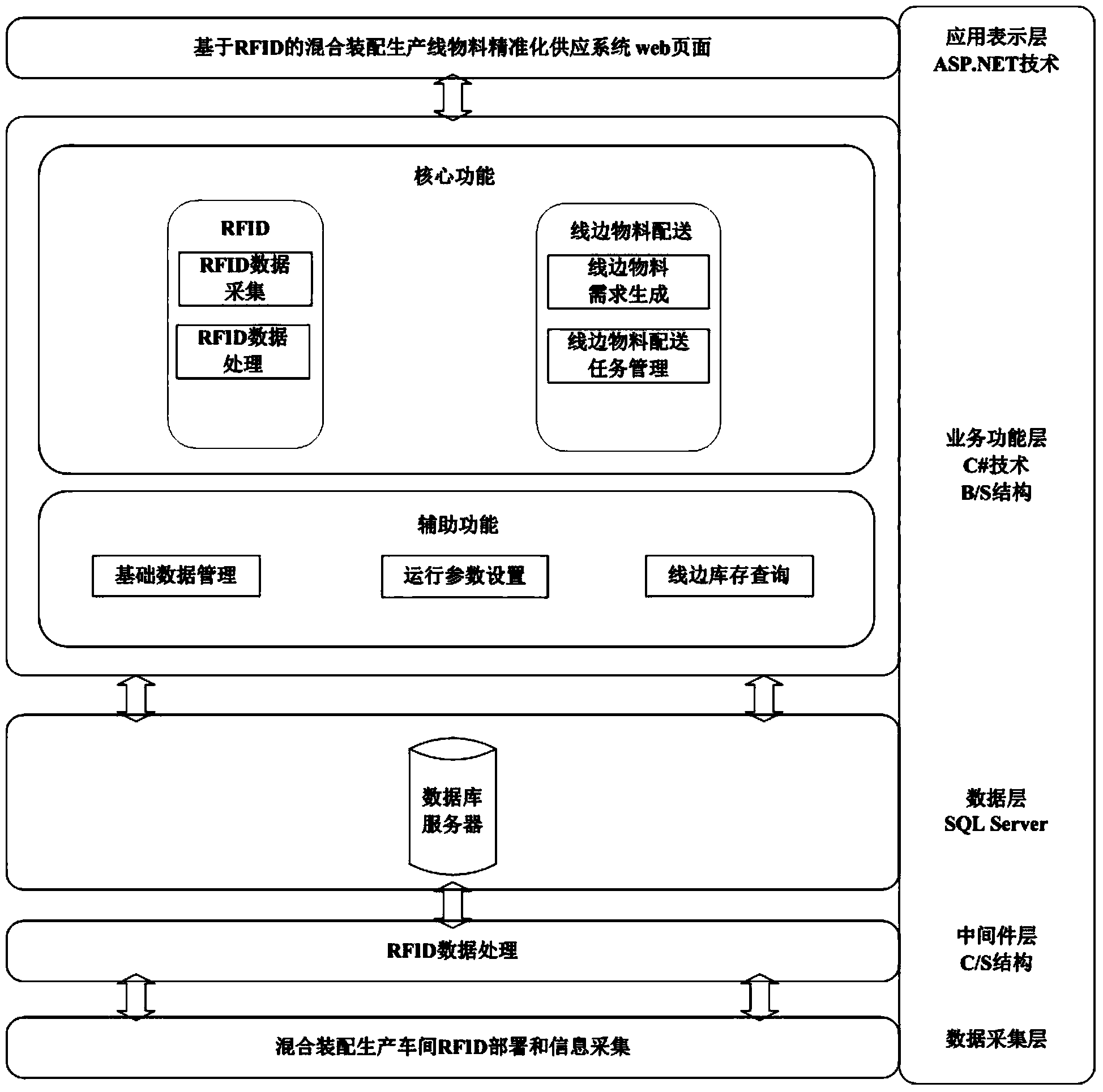

[0042] The material supply system of the RFID-based mixed assembly production line of the present invention is to equip the corresponding RFID tags on the products to be assembled, wherein the RFID tags are installed on the top or front side of the products to be assembled; through RFID reading and writing equipment, middleware And the data storage and application modules process the materials at the production line, specifically as figure 2 shown. Each assembly station on the assembly line is equipped with RFID read-write equipment. The RFID read-write equipment uses the wireless communication proto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com