Manufacturing method of thin film transistor

A technology of thin-film transistors and manufacturing methods, applied in the field of microelectronics, capable of solving problems such as TFT device hysteresis, high defect density, and TFT performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

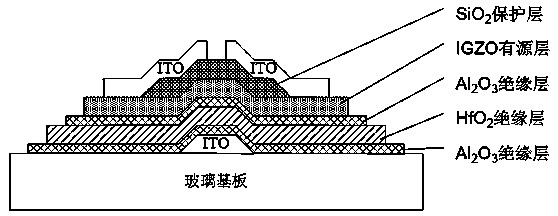

[0020] Such as figure 1 As shown, a method for manufacturing a thin film transistor has the following steps:

[0021] 1) Cleaning of the glass substrate: ultrasonically clean the glass in acetone, ethanol and deionized water for half an hour each to obtain a clean substrate;

[0022] 2) The ITO gate was prepared on the substrate by DC magnetron sputtering, and the sputtering conditions were: the background vacuum was 1.0×10 4 Pa, the gas pressure during sputtering is 0.7Pa, the flow rate of argon gas is 40sccm, the flow rate of oxygen gas is 0.5sccm, and the resistivity of the prepared ITO is 6.2×10 -4 Ω·cm, light transmittance above 80%. The thickness of the prepared film is 100nm, and the prepared film is glued, baked, photolithography, developed, etched and degummed to form an ITO electrode;

[0023] 3) Preparation of the first layer of Al 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com