Device and preparation method for improving luminous efficiency of silicon nitride-based thin-film light-emitting diodes

A technology of silicon nitride film and light-emitting diodes, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the injection barrier, unfavorable light output, and reducing the surface emission efficiency of light, so as to achieve the improvement of luminous intensity, Achieve silicon-based monolithic optoelectronic integration and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

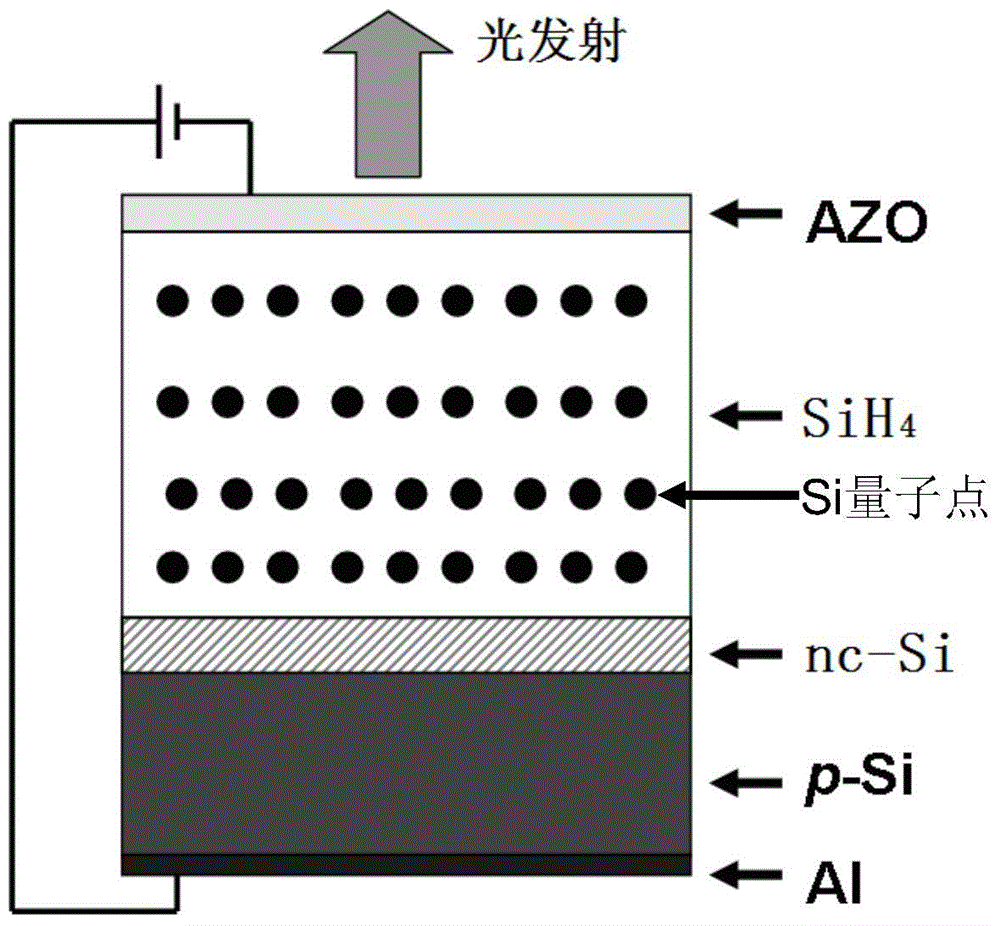

[0030] The specific steps of the method for improving the luminous efficiency of the silicon nitride-based thin-film light-emitting diode in this embodiment are as follows:

[0031] The first step is to use the parallel plate capacitive radio frequency plasma enhanced chemical vapor deposition method to pass SiH 4 And H 2 Gas, deposit a hydrogen-containing amorphous silicon (a-Si:H) film with a thickness of 5nm on the p-Si substrate; the specific equipment control parameters are: RF source power 30W, temperature: 250±10℃, SiH 4 Flow rate: 1.5sccm, H 2 The flow rate is controlled at 10 sccm, the air pressure is controlled at 60 Pa, and the deposition time is controlled at 75 seconds.

[0032] The second step, after forming a-Si:H film, pass in SiH 4 , NH 3 And H 2 Gas, on the a-Si:H film, deposit 50nm thick silicon nitride (SiN x :H) Thin film is used as the light-emitting active layer; the specific equipment control parameters are: the specific equipment control parameters are: RF so...

Embodiment 2

[0041] In this embodiment, the luminous efficiency of the silicon nitride-based thin film light-emitting diode is improved by the following steps:

[0042] The first step is to use the parallel plate capacitive radio frequency plasma enhanced chemical vapor deposition method to pass SiH 4 And H 2 Gas, deposit a hydrogen-containing amorphous silicon (a-Si:H) film with a thickness of 10nm on the p-Si substrate; the specific equipment control parameters are: RF source power 30W, temperature: 250±10℃, SiH 4 Flow rate: 1.5sccm, H 2 The flow rate is controlled at 10 sccm, the air pressure is controlled at 60 Pa, and the deposition time is controlled at 150 seconds.

[0043] The second step, after forming a-Si:H film, pass in SiH 4 , NH 3 And H 2 Gas, on the a-Si:H film, deposit 50nm thick silicon nitride (SiN x :H) Thin film is used as the light-emitting active layer; the specific equipment control parameters are: the specific equipment control parameters are: RF source power 30W, temperat...

Embodiment 3

[0048] In this embodiment, the luminous efficiency of the silicon nitride-based thin film light-emitting diode is improved by the following steps:

[0049] The first step is to use the parallel plate capacitive radio frequency plasma enhanced chemical vapor deposition method to pass SiH 4 And H 2 Gas, deposit a hydrogen-containing amorphous silicon (a-Si:H) film with a thickness of 20nm on the p-Si substrate; the specific equipment control parameters are: RF source power 30W, temperature: 250±10℃, SiH 4 Flow rate: 1.5sccm, H 2 The flow rate is controlled at 10 sccm, the air pressure is controlled at 60 Pa, and the deposition time is controlled at 300 seconds.

[0050] The second step, after forming a-Si:H film, pass in SiH 4 , NH 3 And H 2 Gas, on the a-Si:H film, deposit 50nm thick silicon nitride (SiN x :H) Thin film is used as the light-emitting active layer; the specific equipment control parameters are: the specific equipment control parameters are: RF source power 30W, temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com