Solid electrolyte material and solid oxide fuel cell provided with same

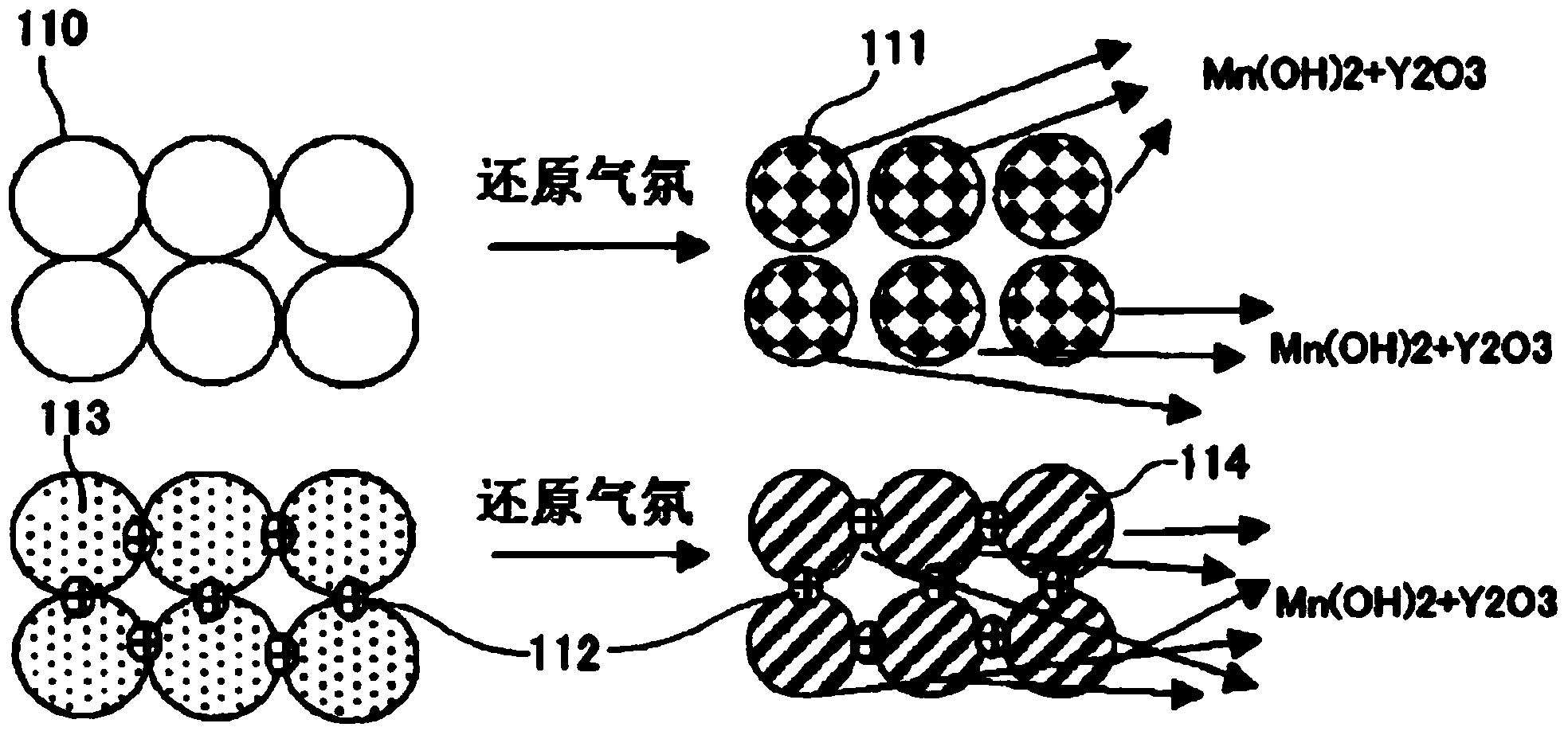

A solid electrolyte and solid oxide technology, used in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of inability to generate electricity and take out power, and achieve the effect of inhibiting pulverization and peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

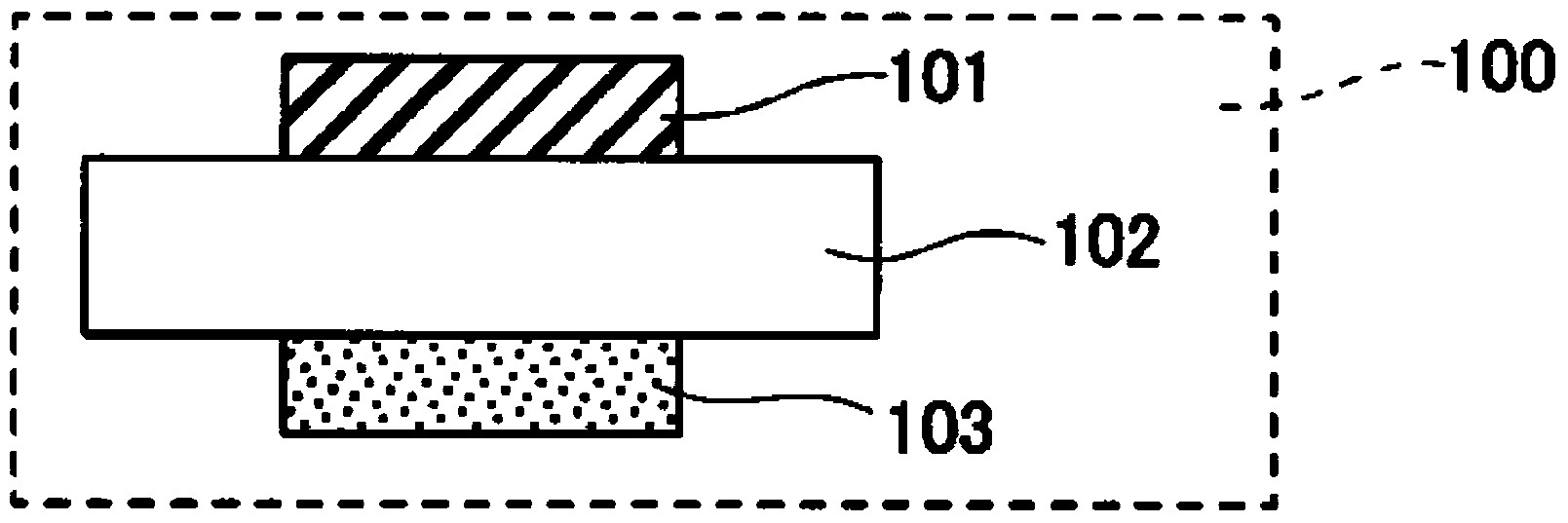

[0038] due to production figure 2 type of single cell and experimented, so it will be described. Weigh as follows, so that ZrO 2 Raw material (average particle size 0.3μm), Y 2 o 3 Raw material (average particle size 0.3μm), CeO 2 Raw material (average particle diameter 0.3 μm) becomes by general formula 89.5mol% (ZrO 2 )-10mol%(Y 2 o 3 )-0.5mol% (CeO 2 ) represents the composition of 10Y0.5CeSZ, wet mixed in solvent ethanol for 50 hours, dried and pulverized, and then sintered at 1200°C. After pulverizing the sintered body into powder, 5 wt % of binder PVA was added to the powder and mixed in a mortar. The powder containing the aforementioned PVA was press-molded at 50 MPa, and sintered at 1450° C. for 5 hr. A dense solid electrolyte layer composed of 10Y0.5CeSZ was obtained. After grinding to a thickness of about 200 μm, use LSM (average particle size 2 μm) as the oxygen electrode layer to form a film by screen printing, so that the thickness after sintering is 20...

Embodiment 2

[0040] In the general formula 89.5mol% (ZrO 2 )-10mol%(Y 2 o 3 )-0.5mol% (CeO 2 ) in the powder composed of 10Y0.5CeSZ, together with the binder PVA, relative to the total mass of zirconia, yttrium oxide, and lanthanide oxides in the solid electrolyte material (total molar mass), mixing is equivalent to 1mol% Al 2 o 3 , and obtained a dense solid electrolyte layer composed of 10Y0.5CeSZ1Al, the same as Example 1 except that.

Embodiment 3

[0042] In the general formula 89.5mol% (ZrO 2 )-10mol%(Y 2 o 3 )-0.5mol% (CeO 2 ) in the 10Y0.5CeSZ composition represented by 1.5 mol% of Al is mixed with respect to the total mass (total molar amount) of zirconia, yttrium oxide, and lanthanide oxides in the solid electrolyte material 2 o 3 , and obtained a dense solid electrolyte layer composed of 10Y0.5CeSZ1.5Al, the same as Example 2 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com