Solid oxide fuel cell

A solid oxide and fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve problems such as inability to extract electricity and power generation, eliminate grain boundary fractures, and improve interparticle strength. , the effect of suppressing powdering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

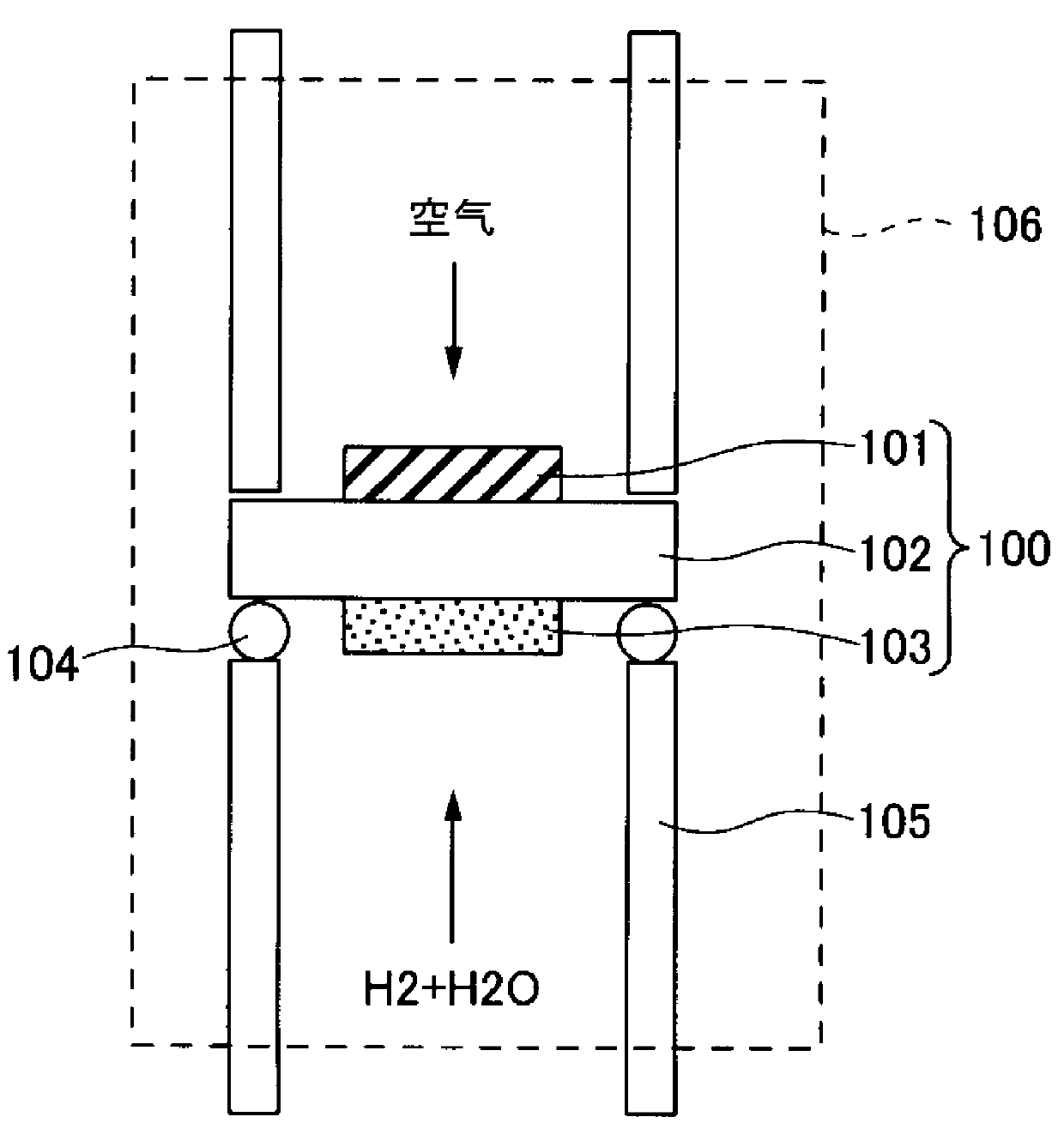

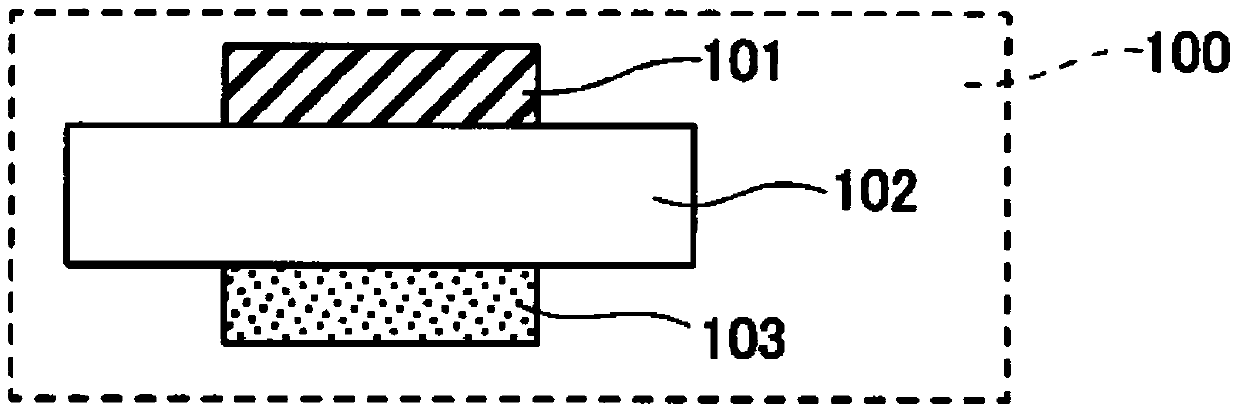

[0037] due to production figure 2 type of single cell and experimented, so it will be described. Weigh as follows, so that ZrO 2 Raw material (average particle size 0.3μm), 5c 2 o 3 Raw material (average particle size 0.3μm), CeO 2 Raw material (average particle diameter 0.3 μ m) becomes by general formula 87mol% (ZrO 2 )-10mol% (Sc 2 o 3 )-3mol% (CeO 2 ) represents the composition of 10Sc3CeSZ, wet mixed in solvent ethanol for 50 hrs, dried and pulverized, and then sintered at 1200°C. After pulverizing the sintered body into a powder, Al is added in an amount corresponding to 2 mol% relative to the total mass (total molar amount) of zirconia, scandium oxide, lanthanide oxide, and / or yttrium oxide in the solid electrolyte material. 2 o 3 (average particle size 0.5 μm), and with respect to the aforementioned powder, 2% by weight of MnO was added in terms of Mn content 2 (average particle diameter 0.5 μm) and 5 wt % of binder PVA were added and mixed in a mortar. The...

Embodiment 2

[0039] In the general formula 87mol% (ZrO 2 )-10mol% (Sc 2 o 3 )-3mol% (CeO 2 ) in the composition of 10Sc3CeSZ, with respect to the total mass of zirconia, scandium oxide, lanthanide oxide and / or yttrium oxide in the solid electrolyte material (total molar mass), mixed with Al equivalent to 2mol% 2 o 3 , adding 2% by weight of Fe based on Fe content 2 o 3 (average particle diameter 0.5 μm) and the binder PVA that adds 5wt% has obtained the solid electrolyte layer of the compact texture of 10Sc3CeSZ2Al composition, and makes the oxygen electrode layer be LSF (average particle diameter 2 μm), in addition and embodiment 1 same.

Embodiment 3

[0041] In the general formula 87mol% (ZrO 2 )-10mol% (Sc 2 o 3 )-3mol% (CeO 2 ) in the composition of 10Sc3CeSZ, with respect to the total mass of zirconia, scandium oxide, lanthanide oxide and / or yttrium oxide in the solid electrolyte material (total molar mass), mixed with Al equivalent to 2mol% 2 o 3 , adding 1% by weight of MnO based on the content of Mn 2 (average particle size 0.5μm), adding 1% by weight of Fe based on Fe content 2 o 3 (average particle diameter 0.5 μm) and the binder PVA that adds 5wt% has obtained the solid electrolyte layer of the compact texture of 10Sc3CeSZ2Al composition, and makes the oxygen electrode layer be LSF (average particle diameter 2 μm), in addition and embodiment 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com