A combination unit for drought-resistant seeding in dry land

A combined unit and dryland technology is applied in the field of combined units for drought-resistant sowing in drylands, which can solve the problems that seeding machinery cannot fully meet agronomic requirements, cannot adapt to agronomic requirements, and high investment costs, so as to improve drought resistance and yield, and enhance resistance to natural disasters. ability, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

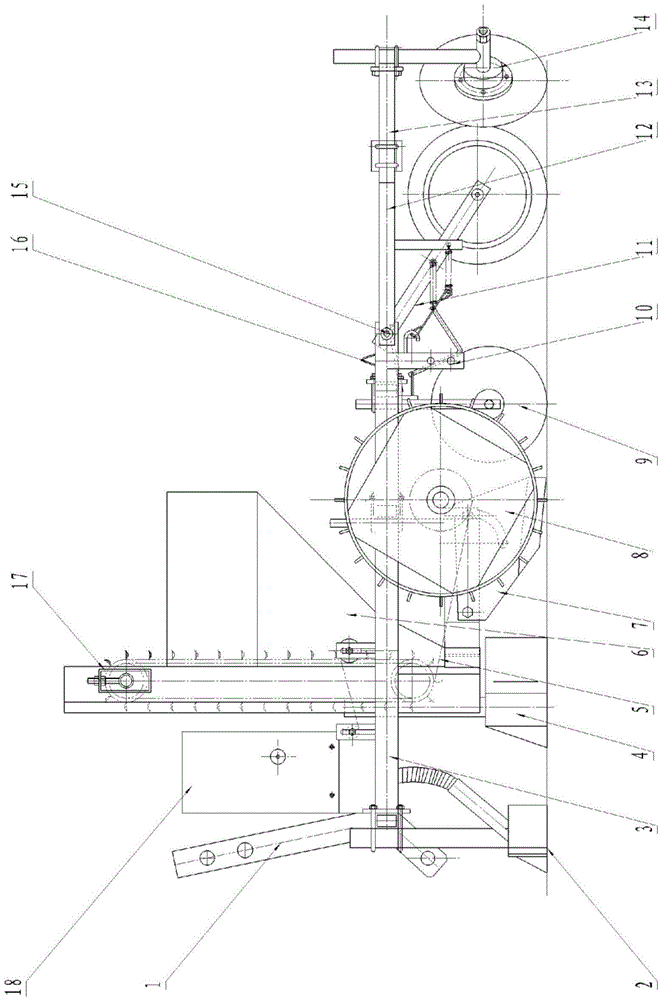

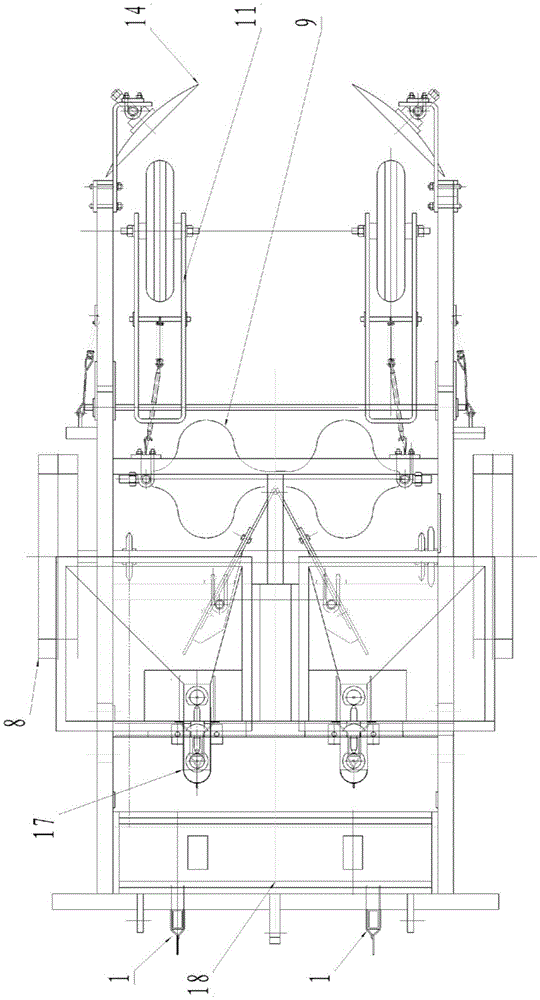

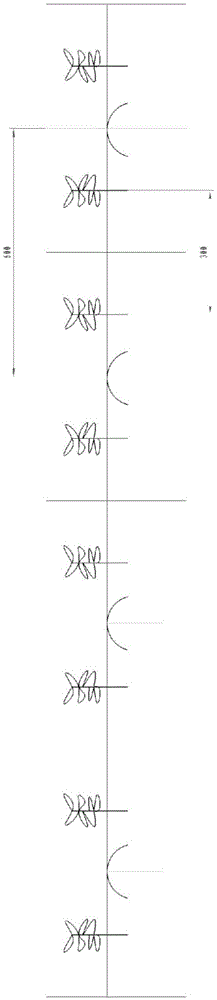

[0027] like figure 1 , figure 2 As shown, the fertilization ditching shovel 2 is fixed on the front beam of the main frame with bolts and U-shaped clamps, and the ditching depth can be adjusted up and down by adjusting the position of the ditching shovel handle on the U-shaped clamps. Or according to crop sowing fertilization plant spacing requirement, also can adjust two ditching shovels 2 spacings left and right along the frame crossbeam. The rear end of each ditching shovel 2 is equipped with a fertilizer delivery pipe, which is connected to the fertilizer discharge pipe of the seed fertilizer box through the pipe. During work, the fertilization ditching shovel ditches the side of the seed bed (about 50mm) while applying fertilizer in the ditch. Sow seed fertilizer to realize layered sowing of seed fertilizer.

[0028] The seed potato ditch opener 4 is installed in the lower end of the seed delivery pipe of the seed potato sorting mechanism 17 . And fix it on the main f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com