Konjak dietary fiber nutrient enrichment rice and preparation method thereof

A technology of nutritionally fortified rice and dietary fiber, which is applied in food preparation, food shearing, food drying, etc., can solve the problems of low dietary fiber content, poor rehydration, and intolerance to boiling, so as to achieve strong taste and overcome poor rehydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

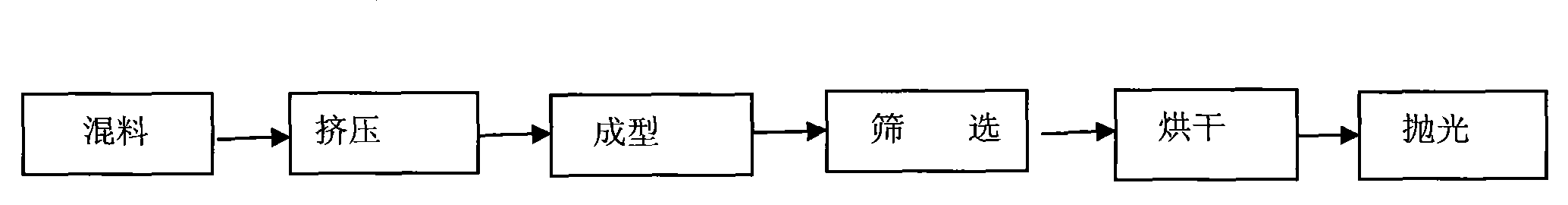

Method used

Image

Examples

Embodiment 1

[0025] 1) Accurately weigh materials according to the following mass ratios: 50% modified starch, 28% corn starch, 0.5% konjac gum, 2% soybean fiber, 0.2% sodium alginate, 0.2% calcium gluconate, 0.5% salt, and 18% water.

[0026] 2) Pour the weighed materials into the mixer, start the mixer to mix the materials evenly, and the order of adding the materials is: first add starch and konjac powder to the mixer and stir evenly, then slowly add water. The rotational speed of the stirrer is 40 rpm, and the stirring time is 15 minutes.

[0027] 3) Put the uniformly mixed material into the twin-screw extrusion molding machine, adjust the cutter speed, and cut the extruded material into strips into the shape of rice grains. Set the temperature in the first zone of the twin-screw extruder to be 40 degrees, the temperature in the second zone to be 90 degrees, and the temperature in the third zone to be 70 degrees. The rotating speed of cutter is 100 rev / min.

[0028] 4) Irregular rice...

Embodiment 2

[0032] 1) Accurately weigh materials according to the following mass ratios: 50% modified starch, 28% corn starch, 1.5% konjac gum, 2% soybean fiber, 0.35% sodium alginate, 0.2% calcium gluconate, 0.5% salt, and 18% water.

[0033] 2) Pour the weighed materials into the mixer, start the mixer to mix the materials evenly, and the order of adding the materials is: first add starch and konjac powder to the mixer and stir evenly, then slowly add water. The rotational speed of the stirrer is 40 rpm, and the stirring time is 15 minutes.

[0034] 3) Put the uniformly mixed material into the twin-screw extrusion molding machine, adjust the cutter speed, and cut the extruded material into strips into the shape of rice grains. Set the temperature in the first zone of the twin-screw extruder to be 40 degrees, the temperature in the second zone to be 90 degrees, and the temperature in the third zone to be 70 degrees. The rotating speed of cutter is 100 rev / min.

[0035] 4) Irregular ric...

Embodiment 3

[0039] 1) Accurately weigh materials according to the following mass ratios: 50% modified starch, 28% corn starch, 3% konjac gum, 2% soybean fiber, 0.5% sodium alginate, 0.2% calcium gluconate, 0.5% salt, and 18% water.

[0040] 2) Pour the weighed materials into the mixer, start the mixer to mix the materials evenly, and the order of adding the materials is: first add starch and konjac powder to the mixer and stir evenly, then slowly add water. The rotational speed of the stirrer is 40 rpm, and the stirring time is 15 minutes.

[0041] 3) Put the uniformly mixed material into the twin-screw extrusion molding machine, adjust the cutter speed, and cut the extruded material into strips into the shape of rice grains. Set the temperature in the first zone of the twin-screw extruder to be 40 degrees, the temperature in the second zone to be 90 degrees, and the temperature in the third zone to be 70 degrees. The rotating speed of cutter is 100 rev / min.

[0042] 4) Irregular rice g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com