Continuous production device and method for band-shaped black conductive foam

A technology of conductive sponge and production device, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of many production processes, the inability of sheet-type products to meet the requirements of large-scale products, and the poor consistency of product performance. Achieve the effect of low cost, good product performance consistency and large width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

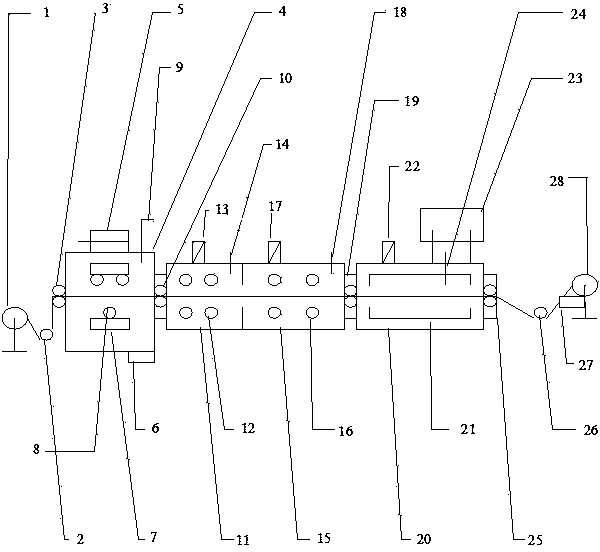

Image

Examples

Embodiment 1

[0023] Embodiment 1: produce strip-shaped black conductive sponge according to the following steps

[0024] First, place the strip-shaped conductive sponge substrate on the unwinding machine, and the strip-shaped conductive sponge substrate passes through the unwinding roller, spraying drive roller, curing drive roller, drying drive roller, cooling drive roller, and winding roller in turn. Winding on the winding machine; then, the conductive sponge substrate passes through the spraying room, pure water, black conductive paint, and nano-metal conductive particles are sprayed into the material storage room according to the mass ratio of 1:8:2, and then sprayed into the mist After atomization in the chamber, the conductive sponge substrate is continuously sprayed by the spray pipe to form a uniform conductive coating on the surface of the conductive sponge substrate. The power of the atomizer is 15kw, and the spraying speed is controlled at 1.5m / min. The thickness of the coating ...

Embodiment 2

[0026] Embodiment 2: produce strip-shaped black conductive sponge according to the following steps

[0027] First, place the strip-shaped conductive sponge substrate on the unwinding machine, and the strip-shaped conductive sponge substrate passes through the unwinding roller, spraying drive roller, curing drive roller, drying drive roller, cooling drive roller, and winding roller in turn. Winding on the winding machine; then, the conductive sponge substrate passes through the spraying room, pure water, black conductive paint, and nano-metal conductive particles are sprayed into the material storage room according to the mass ratio of 1:8:2, and then sprayed into the mist After atomization in the chamber, the conductive sponge substrate is continuously sprayed by the spray pipe to form a uniform conductive coating on the surface of the conductive sponge substrate. The power of the atomizer is 18kw, and the spraying speed is controlled at 2.0m / min. The thickness of the coating ...

Embodiment 3

[0029] Embodiment 3: produce strip-shaped black conductive sponge according to the following steps

[0030] First, place the strip-shaped conductive sponge substrate on the unwinding machine, and the strip-shaped conductive sponge substrate passes through the unwinding roller, spraying drive roller, curing drive roller, drying drive roller, cooling drive roller, and winding roller in turn. Winding on the winding machine; then, the conductive sponge substrate passes through the spraying room, pure water, black conductive paint, and nano-metal conductive particles are sprayed into the material storage room according to the mass ratio of 1:8:2, and then sprayed into the mist After atomization in the chamber, the conductive sponge substrate is continuously sprayed by the spray pipe to form a uniform conductive coating on the surface of the conductive sponge substrate. The power of the atomizer is 20kw, and the spraying speed is controlled at 3.0m / min. The thickness of the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com