Nondestructive technology for disassembling landing leg pin shaft in concrete pump truck remanufacturing process

A concrete pump truck and remanufacturing technology, which is applied in the fields of motor vehicle and vehicle scrap recycling, solid waste removal, etc., to avoid damage, solve production bottleneck problems, and improve dismantling production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

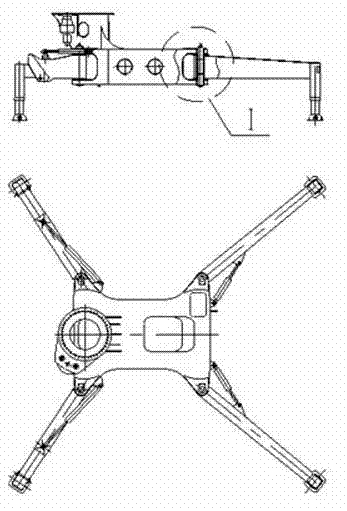

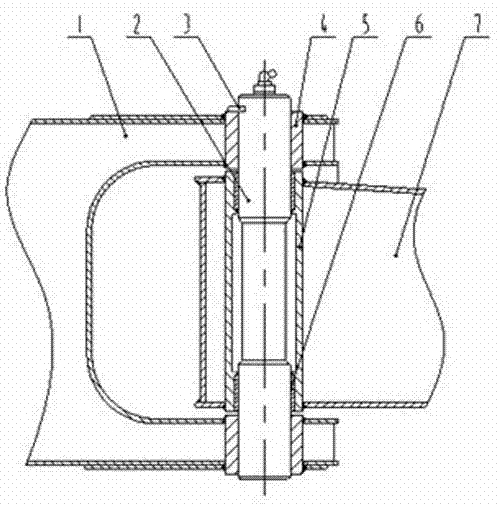

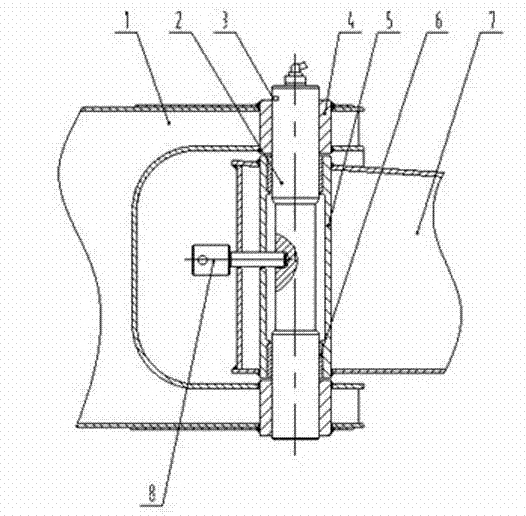

[0019] see figure 1 , 2 , 3. The specific process steps of the present invention are: apply enough rust remover to the rusted part of the outrigger pin and the bushing and soak; swing the outrigger at a certain angle, drill a hole in the middle of the bushing with a copper sleeve, and drill to the pin The depth of the hole on the shaft is 20-40 mm, and insert the positioning pin in the hole to lock the original rotating shaft sleeve and the outrigger pin; slowly swing the outrigger left and right to make the rusted part of the outrigger pin and the shaft sleeve Relatively rotate; continue to add rust remover to the rusted part of the outrigger pin and the bushing, increase the swing range of the outrigger, so that the relative rotation of the outrigger pin and the bushing is flexible; take out the positioning pin, and use a jack to push out Outrigger pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com