Compost preparation system and compost preparation method

A technology of a manufacturing system and a manufacturing method, which is applied to the preparation of organic fertilizers, organic fertilizers, and fertilization devices, etc., can solve the problems of increased manufacturing costs, increased consumption of heating air and electricity, and low heating efficiency of composting raw materials, and achieves high-efficiency heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Next, the present invention will be described based on the drawings shown in the examples.

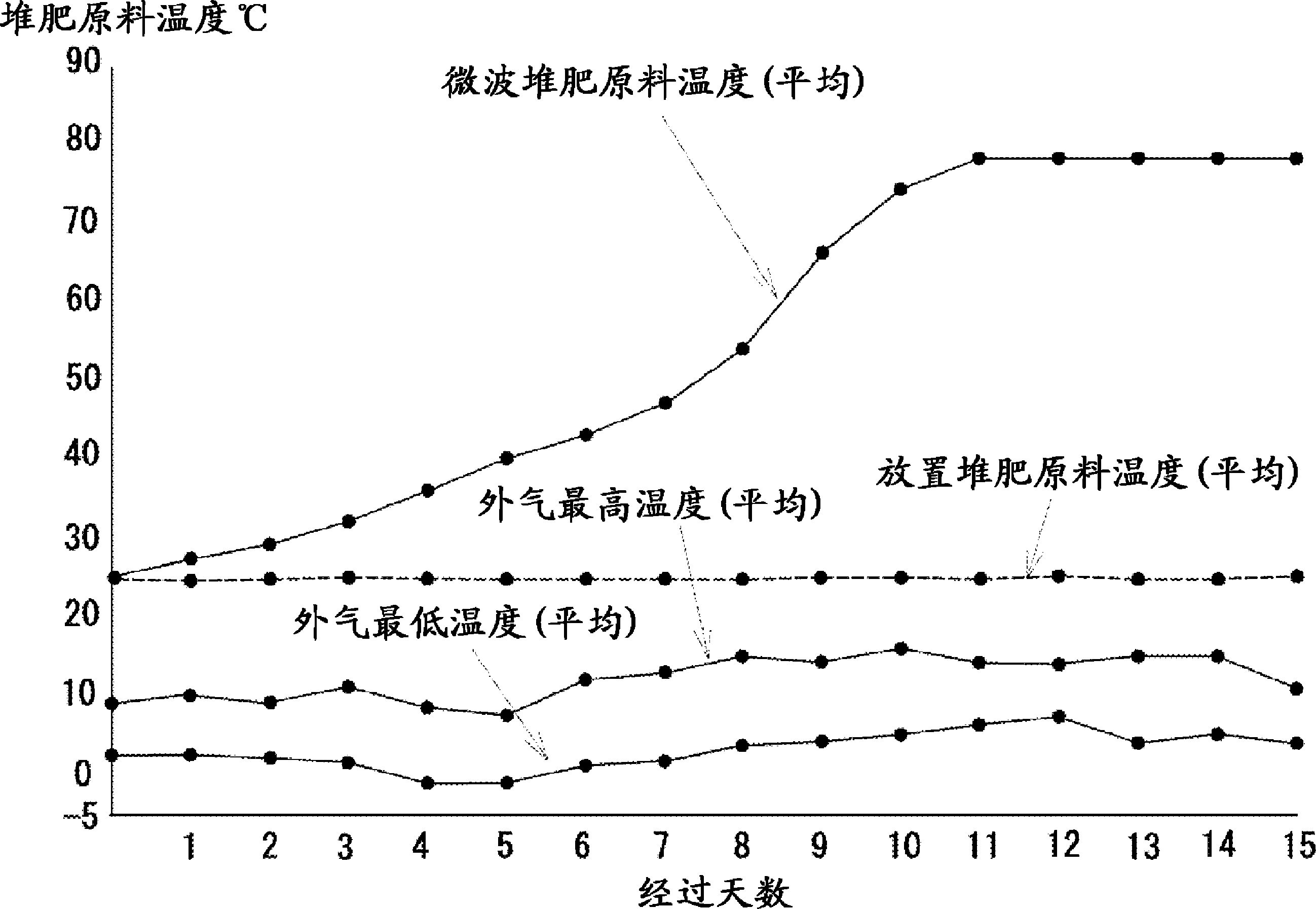

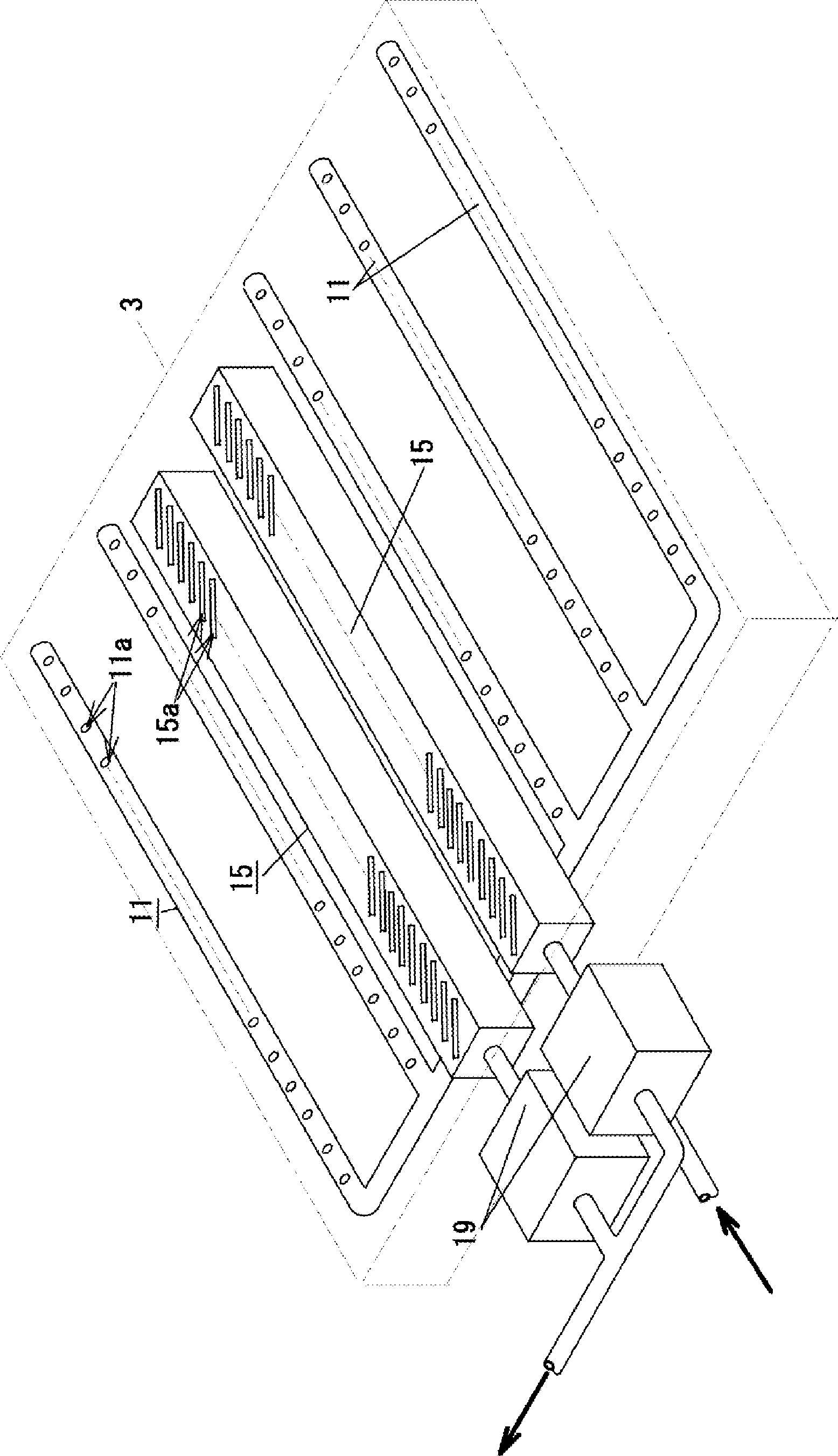

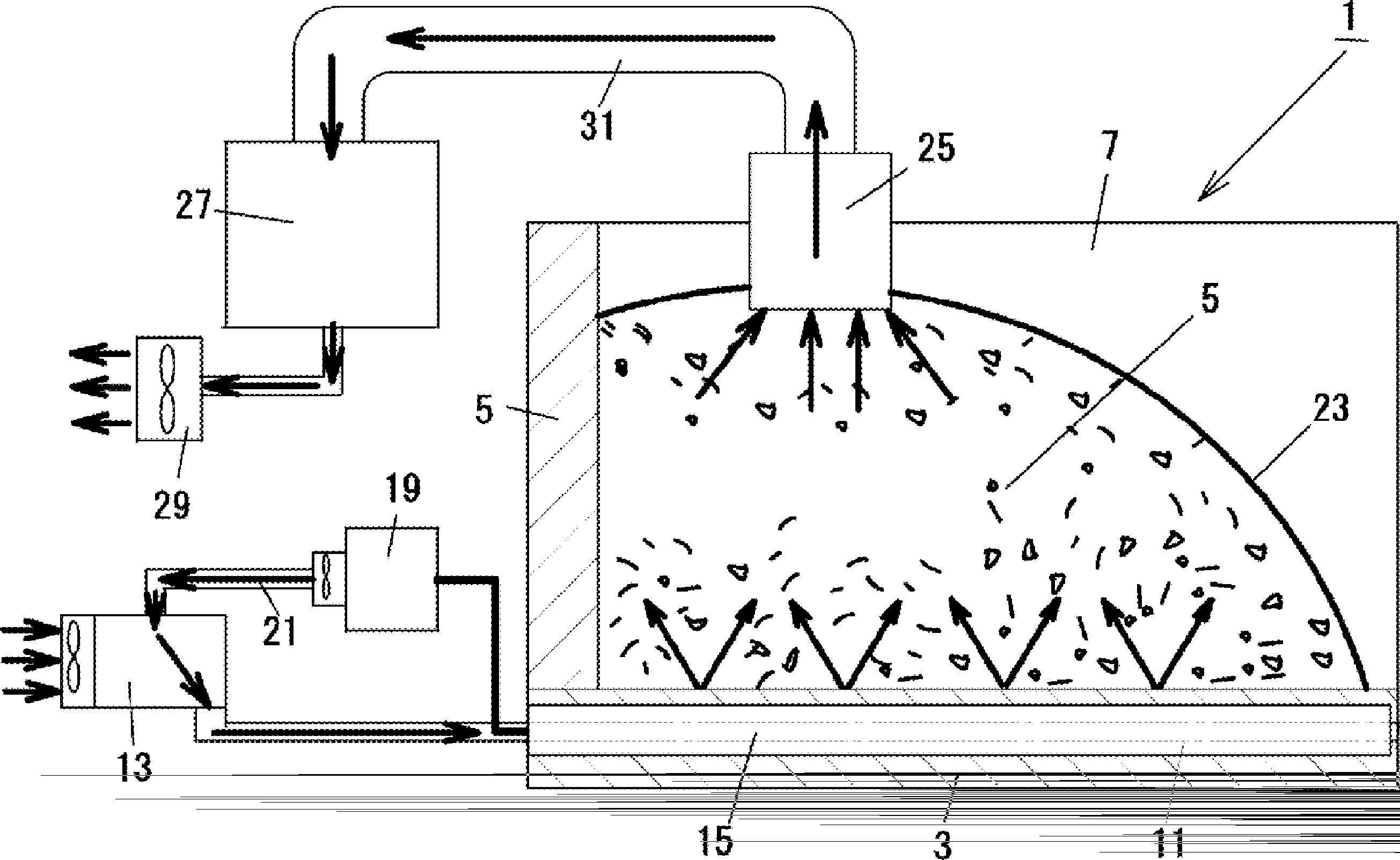

[0018] Such as figure 1 and figure 2 As shown, the compost raw material accumulation tank 1 of the compost manufacturing system is provided with a side wall with a height of 5.7 corresponding to the accumulation capacity upright on both sides and the inner surface of the bed surface 3 of the required area, and its front is open. Then, on the bed surface 3 of the above-mentioned compost raw material accumulation tank 1, compost raw materials 9 such as livestock manure (cow manure, pig manure, chicken manure, etc.) or kitchen waste are accumulated. The above-mentioned compost raw material 9 itself contains a large amount of water, but when the heat treatment by microwaves described later is performed, if the water content is small, it needs to be adjusted to at least 60%wt.

[0019] In addition, the above-mentioned compost raw material 9 itself contains aerobic or anaerobic mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com