Method for preparing olefin by utilizing coke-oven gas and calcium carbide furnace tail gas

A technology for calcium carbide furnace tail gas and coke oven gas, which is applied in the fields of hydrocarbon production from carbon oxides, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as waste of energy, environmental pollution, etc. The effect of reducing environmental pollution and increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

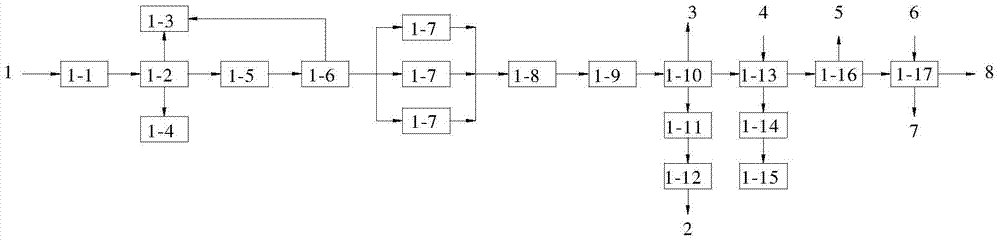

[0032] In conjunction with the accompanying drawings, the technical solution of the present invention is further described.

[0033] The purification process of coke oven gas is as follows:

[0034] (1) The crude gas 1 from the coking section is dedusted by the dust collector 1-1, and then passes through the gas-liquid separator 1-2 (about 80~85°C), where the gas, tar and ammonia water are separated, and the ammonia water enters the circulating ammonia Sink 1-4, tar 5 enters tar tank 1-3 and stores. The crude gas enters the cooler 1-5 to cool to 20-22°C, enters the electric tar collector 1-6 to trap tar droplets, and recovers it to the tar tank 1-3.

[0035] (2) The naphthalene in the raw gas is removed by an adsorption device composed of several activated carbon adsorption towers 1-7. At room temperature, the naphthalene in the raw gas is adsorbed by the activated carbon. When the adsorption reaches saturation, it can switch to regeneration operation, such as 10 At least 1~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com