Method for step by step extracting avermectin B1a and B2a from mycelium

A technology of abamectin and mycelium, which is applied in the field of step-by-step extraction of B1a and B2a components, can solve the problems of separation and inability to separate, and achieve less impurities, high extraction rate and high crystallization yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0010] Example 1, different moisture content to B 1a and B 2a Effect of Extraction Rate

[0011] The abamectin mycelium powder used in the experiment was provided by Zhejiang Shenghua Baike Co., Ltd.: the water content in the mycelium was 13-16%, B 1a Content is 14%, B 2a The content is 12%; the experiment is divided into 7 groups, respectively numbered NO.1~NO.7, one bottle for each group, and 7 parts of mycelium powder are accurately weighed, each 10.0g, and the 250ml of each group is filled with a triangle bottle, and then add 100 mL of methanol or water / methanol co-solvent to each bottle separately, as follows:

[0012] NO.1 Add 100ml of methanol with a purity of 99.5%

[0013] NO.2 Add 100ml water / methanol (2:8, volume ratio)

[0014] NO.3 Add 100ml water / methanol (3:7, volume ratio)

[0015] NO.4 Add 100ml water / methanol (4:6, volume ratio)

[0016] NO.5 Add 100ml water / methanol (4.5:5.5, volume ratio)

[0017] NO.6 Add 100ml water / methanol (5:5, volume ratio)

...

example 2

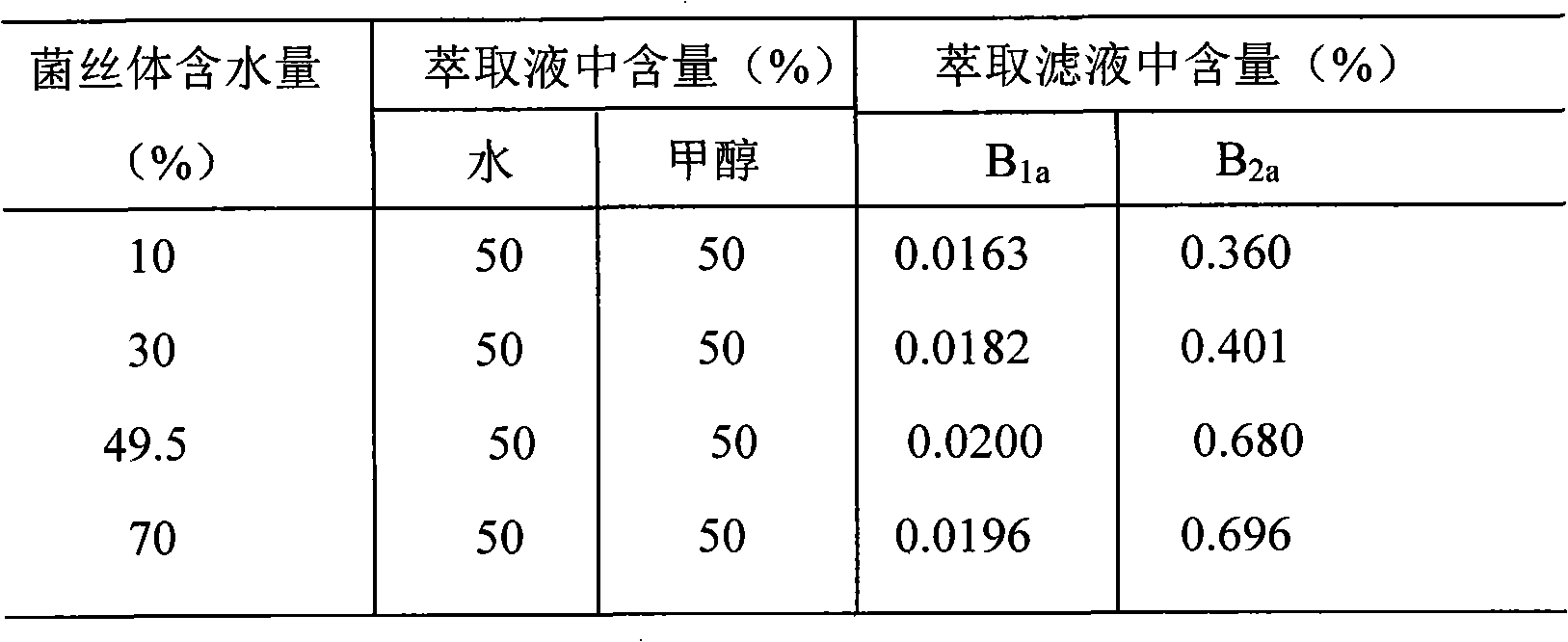

[0029] Example 2, the influence of mycelia water content on the extraction effect

[0030] Three kinds of mycelia with different water contents were used in the experiment to extract B with methanol / water co-solvent 2a , the consumption of methanol / water co-solvent is 10 times of mycelium weight (on a dry basis), and the leaching time is 3 hours, and the experimental results are shown in the following table.

[0031]

[0032] Note: The extract refers to the mixed system composed of mycelium, water and methanol.

[0033] From the above experimental results, it can be seen that extracting B with about 50% water content mycelium 2a suitable.

example 3

[0034] Example 3, extract B from the mycelium filter cake of water content 45~50% 1a and B 2a

[0035] Take 100g water content is 45 ~ 50%, containing B 1a 6.12%, B 2a Add 1 liter of methanol / water (52 / 48) to the 4.9% mycelium filter cake, stir and extract for 2 hours, and then filter with suction to obtain the first extraction filtrate and fungus residue A.

[0036] HPLC analysis: B in the first extraction filtrate 2a The concentration is 0.51%, the filtrate contains B 2a The total amount is 3.92g, B 1a The concentration is 0.016%, the filtrate contains B 1a The total amount is 0.126 g.

[0037] The fungus residue A was extracted twice with 10 times the volume of methanol / water (50 / 50), and suction filtered to obtain the second extraction filtrate and the fungus residue B.

[0038] HPLC analysis: B in the second extraction filtrate 2a The concentration is 0.12%, the total amount is 1.02g, B 1a The concentration is 0.0192%, and the total amount is 0.1536g.

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com