Gear oil composition and preparation method thereof

A technology of composition and gear oil, which is applied in the field of lubricating oil, and can solve the problems of oil emulsification and poor water separation of gear oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of gear oil composition, comprises the following steps:

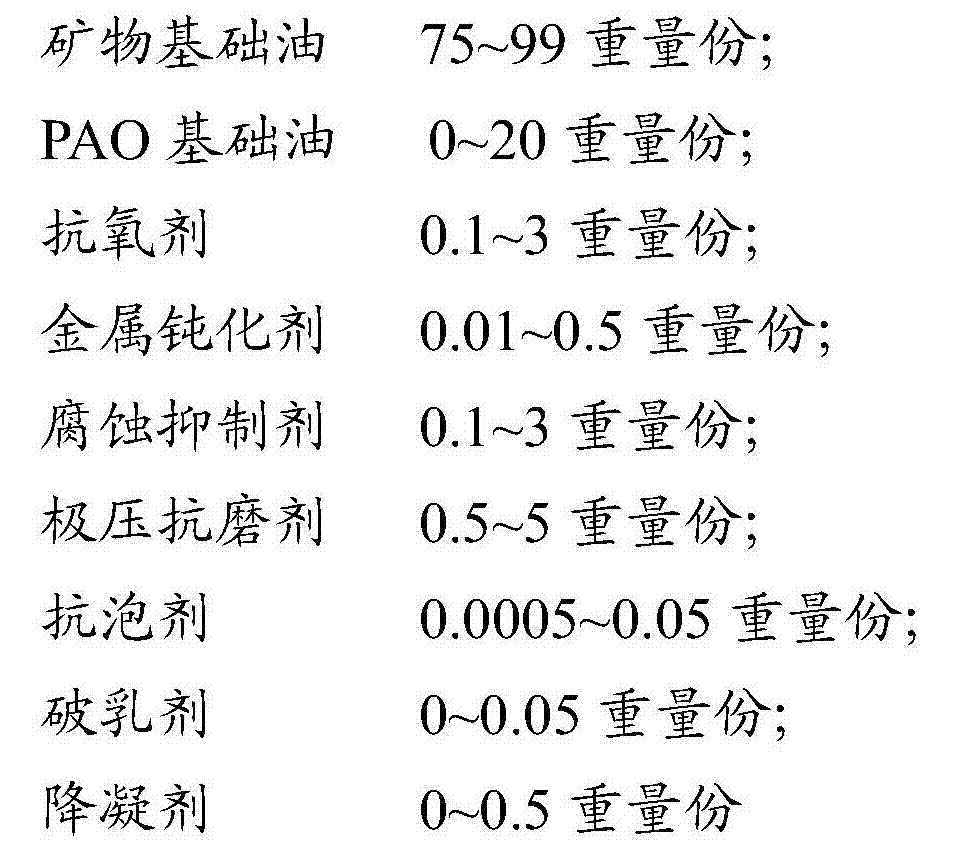

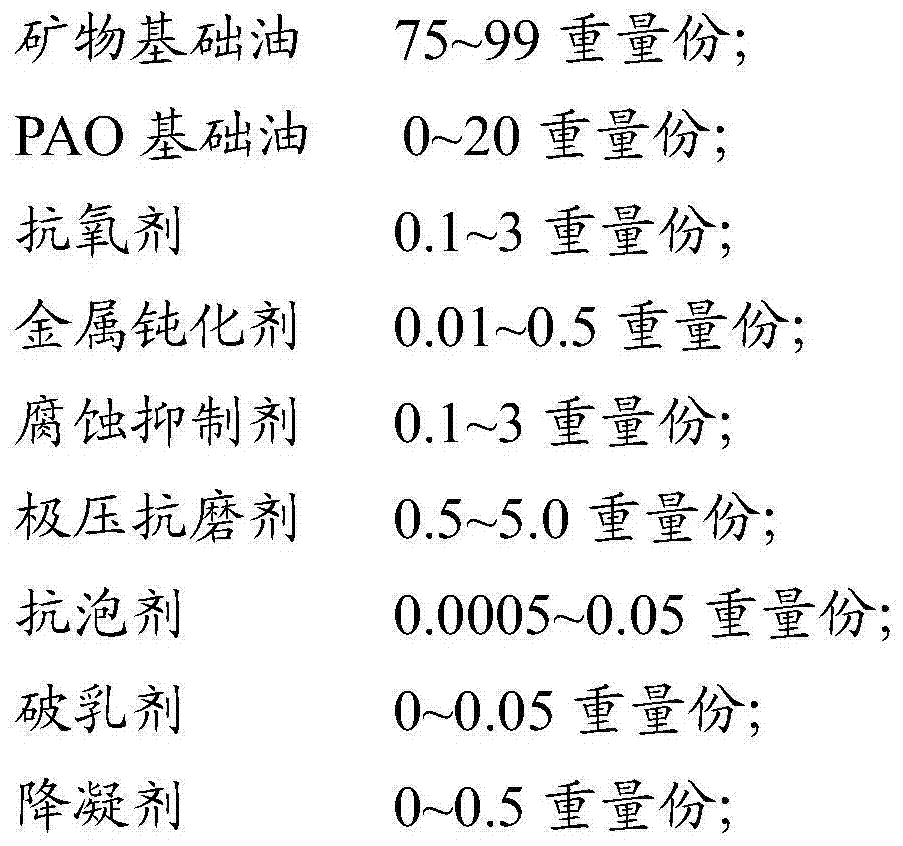

[0049] 0.1 to 3 parts by weight of antioxidant, 0.01 to 0.5 parts by weight of metal passivator, 0.1 to 3 parts by weight of corrosion inhibitor, 0.5 to 5.0 parts by weight of extreme pressure antiwear agent, 0.0005 to 0.05 parts by weight of Antifoaming agent, 0-0.05 parts by weight of demulsifier, 75-99 parts by weight of mineral base oil and 0-20 parts by weight of PAO base oil are mixed and stirred evenly to obtain a gear oil composition. The metal passivator is selected from One or more of benzotriazole derivatives, thiadiazole derivatives and organic amine compounds; the corrosion inhibitor is selected from one of fatty acids, fatty acid derivatives, sulfonates and complex phosphate compounds or several; the corrosion inhibitor is selected from one or more of fatty acids, fatty acid derivatives, sulfonates and complex phosphate compounds; the ...

Embodiment 1

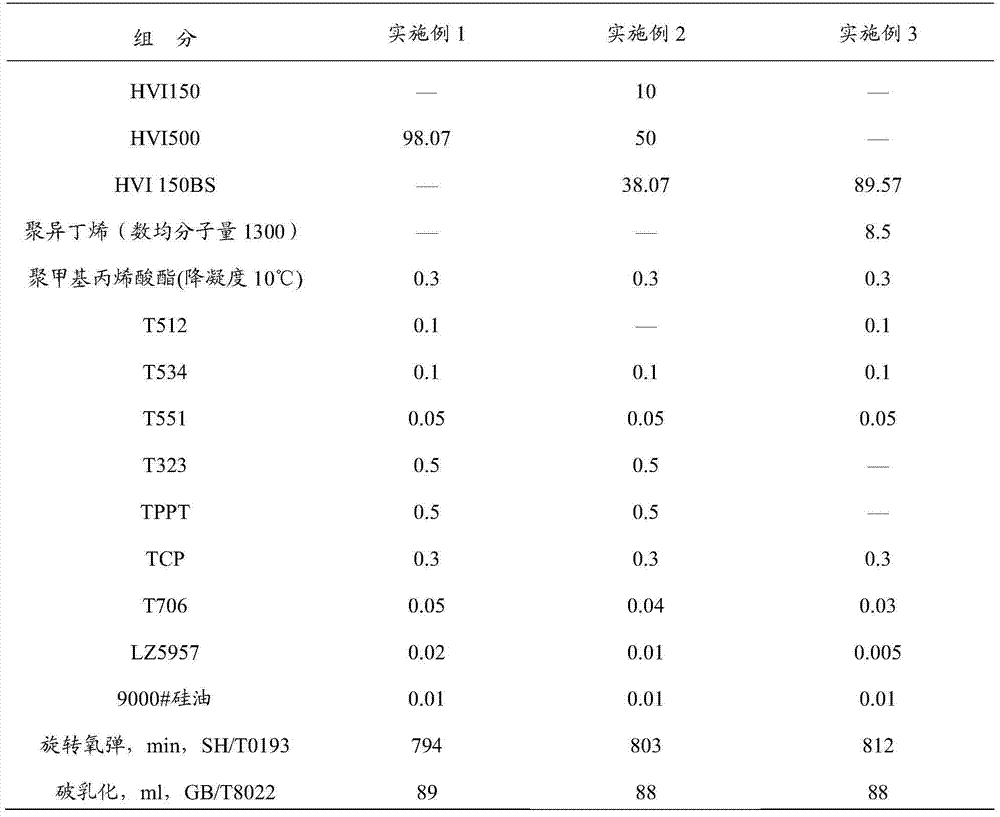

[0056] Add antioxidants, metal passivators, corrosion inhibitors, extreme pressure antiwear agents, antifoaming agents, and demulsifiers to mineral base oil and PAO base oil in sequence according to the grades and contents of the component types in Table 1. , and stir evenly to obtain a gear oil composition.

[0057] The performance of the gear oil composition obtained in Example 1 was tested according to standards such as SH / T0193, GB / T8022 and GB / T7305, and the results obtained are shown in Table 1.

Embodiment 2

[0059] Add antioxidants, metal passivators, corrosion inhibitors, extreme pressure antiwear agents, antifoaming agents, and demulsifiers to mineral base oil and PAO base oil in sequence according to the grades and contents of the component types in Table 1. , and stir evenly to obtain a gear oil composition.

[0060] According to the standards of SH / T0193, GB / T8022 and GB / T7305, the performance of the gear oil composition obtained in Example 2 was tested, and the results obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com