Phosphating solution and phosphating method

A phosphating solution and fluoride technology, which is applied in the coating process of metal materials, etc., can solve the problems that are not conducive to the phosphating of iron and zinc in the same tank, high energy consumption of the process, and prolonged phosphating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

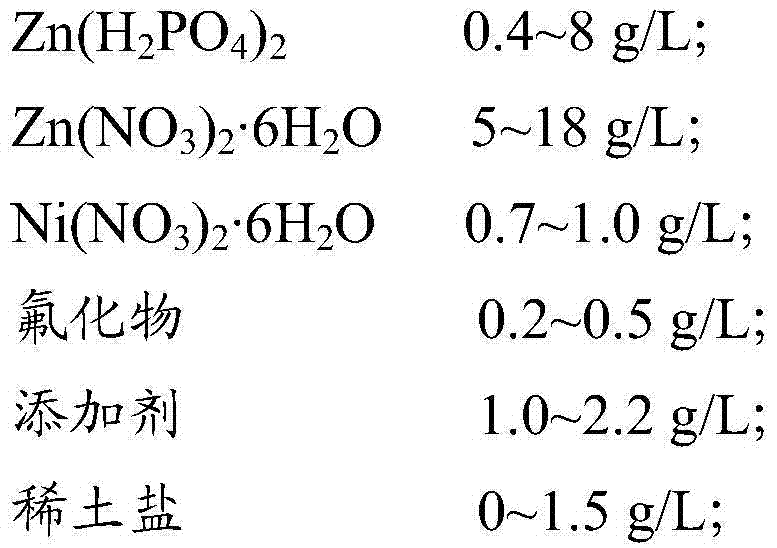

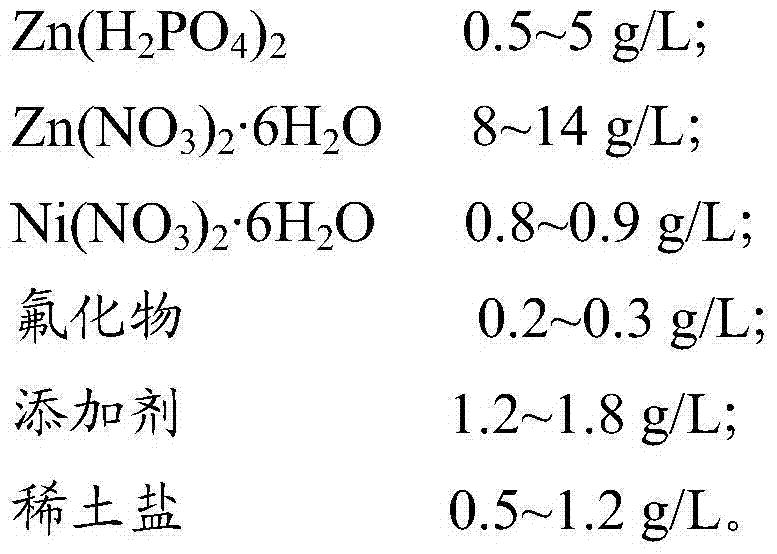

Method used

Image

Examples

Embodiment 1

[0050] The galvanized steel sheet was degreased in a degreasing solution at 50°C for 5 min, washed with hot water and flowing water, and then treated in an acid etching solution for 10 min at room temperature. After treatment for 40s, without water washing, directly into the phosphating solution, heating to a temperature of 42°C in a water bath, and phosphating for 5 minutes to obtain a phosphatized galvanized steel sheet. The composition of phosphating solution is: Zn(H 2 PO 4 ) 2 1g / L, Zn(NO 3 ) 2 ·6H 2 O10g / L, Ni(NO 3 ) 2 ·6H 2 O0.8g / L, sodium fluoride 0.2g / L, sodium citrate 1.5g / L, cerium nitrate 1.2g / L, the balance of water; FA is 1.8 points, TA is 10.5 points, TA / FA is 5.4 points .

[0051] The galvanized steel sheet after phosphating treatment obtained in Example 1 is analyzed, and the obtained phosphating film is gray, the film layer is uniform and dense, and the average film weight is 2.24g / m2 3 .

[0052] The phosphated galvanized steel sheet obtained in E...

Embodiment 2

[0055] Degrease the galvanized steel sheet in a degreasing solution at 50°C for 5 minutes. After washing with hot water and flowing water, treat the treated galvanized steel sheet in a surface conditioning solution for 40s at room temperature without washing, and directly enter the phosphating solution. The water bath was heated to a temperature of 42° C., and the phosphating treatment was carried out for 5 min to obtain a galvanized steel sheet after the phosphating treatment. The composition of phosphating solution is: Zn(H 2 PO 4 ) 2 3g / L, Zn(NO 3 ) 2 ·6H 2 O8g / L, Ni(NO 3 ) 2 ·6H 2 O0.8g / L, sodium fluoride 0.2g / L, sodium salicylate 1.5g / L, cerium nitrate 1.2g / L, the balance of water; FA is 1.7 points, TA is 10.5 points, TA / FA is 6.2 point.

[0056] The galvanized steel sheet after phosphating treatment obtained in Example 2 was analyzed, and the obtained phosphating film was gray, and the film layer was uniform and dense.

Embodiment 3

[0058]Degrease the hot-dip galvanized steel sheet in a degreasing solution at 50°C for 5 min, wash with hot water and flowing water, and then treat it in an acid etching solution for 10 min at room temperature, and then adjust the galvanized steel sheet after acid etching on the surface. The solution was treated at room temperature for 40s, without washing, directly into the phosphating solution, heated to a temperature of 38°C in a water bath, and phosphatized for 4 minutes to obtain a phosphated galvanized steel sheet. The composition of phosphating solution is: Zn(H 2 PO 4 ) 2 1g / L, Zn(NO 3 ) 2 ·6H 2 O9g / L, Ni(NO 3 ) 2 ·6H 2 O0.8g / L, sodium fluoride 0.2g / L, sodium salicylate 1.2g / L, cerium nitrate 1.2g / L, the balance of water; FA is 1.7 points, TA is 16 points, TA / FA is 9.4 point.

[0059] The galvanized steel sheet after phosphating treatment obtained in Example 3 was analyzed, and the obtained phosphating film was gray, and the film layer was uniform and dense. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com