A method of heating cladding alloys on rails to solve poor branching

A technology for cladding alloys and bad shunting, applied in metal material coating process, coating, etc., can solve problems such as bad shunting, wear of alloy strips, waste of energy, etc., and achieve good shunting, concentrated heating, and utilization of thermal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

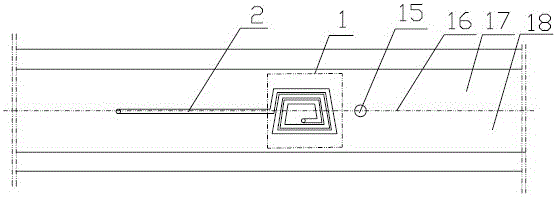

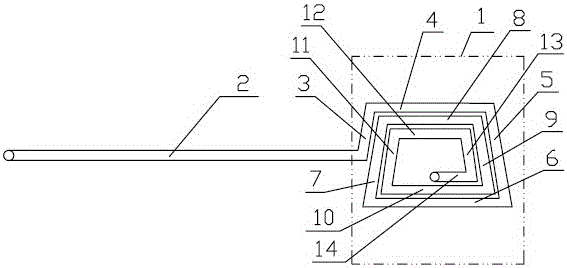

[0032]A method for heating cladding alloys on rails to solve poor shunting. The welding torch 15 is arranged above the rail tread to be clad, and the planar induction heater is arranged behind the welding torch 15. The planar induction heater is located at the same The first heating surface 1 and the second heating surface 2 are connected together on the horizontal plane. The first heating surface 1 is trapezoidal or square or circular, and the second heating surface 2 is in the shape of a "one". The horizontal position of the rail tread is adjustable. The welding torch 15 moves longitudinally along the rail tread to clad alloy powder on the rail tread to be clad to form an alloy strip. The planar induction heater also moves with the welding torch 15 and heats the rail tread. The moving speed of the planar induction heater Same as the moving speed of welding torch 15.

[0033] This embodiment is the most basic implementation. According to the wheel-rail contact theory, the whe...

Embodiment 2

[0035] A method for heating cladding alloys on rails to solve poor shunting. The welding torch 15 is arranged above the rail tread to be clad, and the planar induction heater is arranged behind the welding torch 15. The planar induction heater is located at the same The first heating surface 1 and the second heating surface 2 are connected together on the horizontal plane. The first heating surface 1 is trapezoidal or square or circular, and the second heating surface 2 is in the shape of a "one". The horizontal position of the rail tread is adjustable. The welding torch 15 moves longitudinally along the rail tread to clad alloy powder on the rail tread to be clad to form an alloy strip. The planar induction heater also moves with the welding torch 15 and heats the rail tread. The moving speed of the planar induction heater Same as the moving speed of welding torch 15. The rail tread to be clad refers to the center 16 of the rail tread or the inner side 17 of the rail tread or...

Embodiment 3

[0038] A method for heating cladding alloys on rails to solve poor shunting. The welding torch 15 is arranged above the rail tread to be clad, and the planar induction heater is arranged behind the welding torch 15. The planar induction heater is located at the same The first heating surface 1 and the second heating surface 2 are connected together on the horizontal plane. The first heating surface 1 is trapezoidal or square or circular, and the second heating surface 2 is in the shape of a "one". The horizontal position of the rail tread is adjustable. The welding torch 15 moves longitudinally along the rail tread to clad alloy powder on the rail tread to be clad to form an alloy strip. The planar induction heater also moves with the welding torch 15 and heats the rail tread. The moving speed of the planar induction heater Same as the moving speed of welding torch 15. The rail tread to be clad refers to the center 16 of the rail tread or the inner side 17 of the rail tread or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com