Method for defect detection and surface measurement of silicon wafer

A defect detection, silicon wafer technology, applied in measuring devices, optical testing flaws/defects, using optical devices, etc., can solve problems such as damage to the surface of the object to be measured, complex design, and inability to measure free-form objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention discloses a method for silicon wafer defect detection and surface shape measurement. The method uses phase deflection profilometry (PMD) in the silicon wafer surface shape measurement. Embodiments of the invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

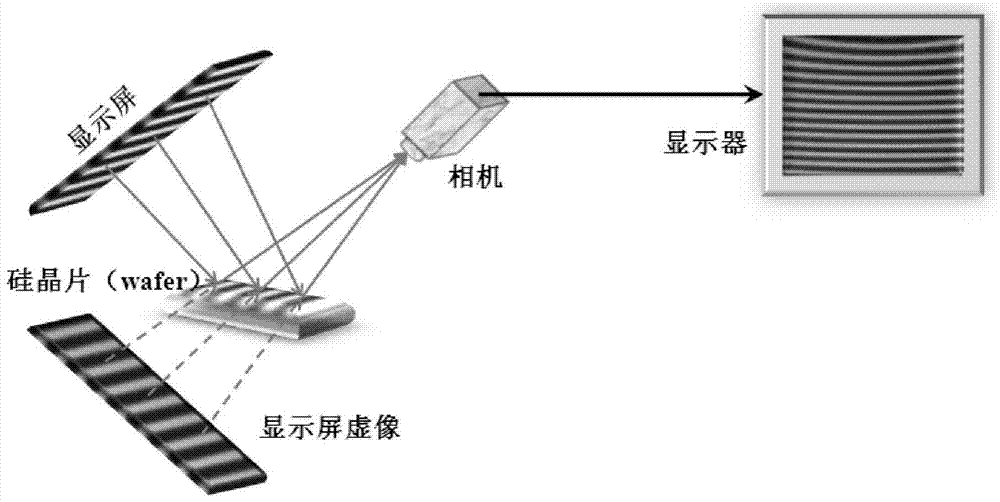

[0032] Step 1: Set up the experimental measurement system: the system mainly includes a camera, a display screen, an object to be measured, a control computer and a stand. The system is adjusted so that the camera sees the fringes on the display through the silicon wafer of the object under test. Such as figure 1 .

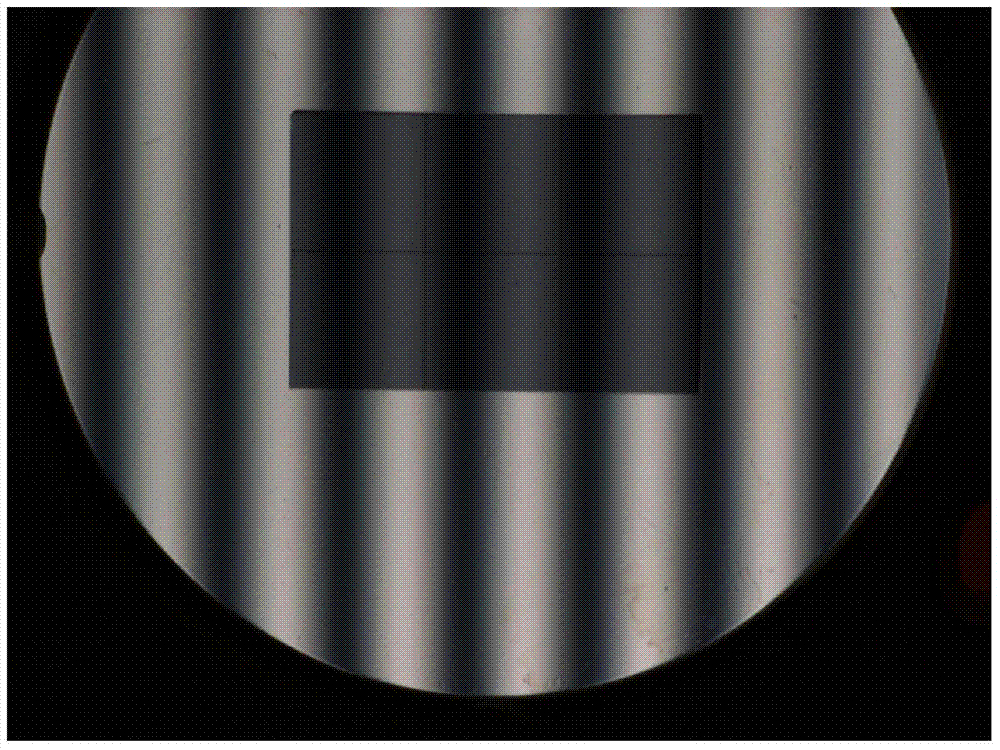

[0033] Step 2: The display screen is controlled by a computer to produce standard horizontal and vertical sinusoidal stripes, and the camera captures the deformed stripes reflected by the wafer. In this example, the CCD camera is Manta G-125B / C, and the camera uses a 50mm fixed-focus lens (Computar M5018-MP2).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com