Method for marking immune globulin by quantum dot

A technology of immunoglobulin and quantum dots, which is applied in the field of quantum dot-labeled immunoglobulins, can solve the problems of large loss of immunoglobulins, reduced activity, and low efficiency, and achieves simple operation and use of equipment, improved utilization, and high activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

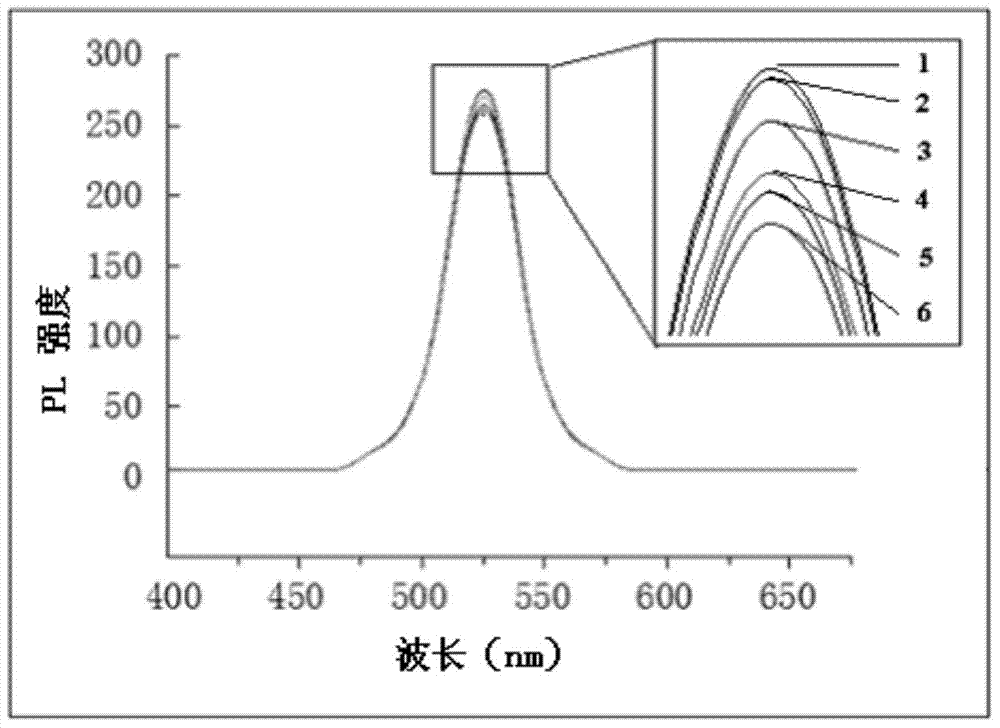

[0026] A CdTe / ZnS core-shell quantum dot-labeled Procalcitonin (PCT) antibody with a fluorescence wavelength of 525 nm was selected.

[0027] (1) Cleaning quantum dots: Take 10 μL of 8 μmol / mL CdTe / ZnS core-shell quantum dots in EP (eppendorf) tubes, and add 2 mL of 10 mmol / L, pH=7.2 phosphate buffer into the EP tubes, mix well and use The 100K ultrafiltration tube was centrifuged at 5000r / min at 25°C for 6min, and the quantum dots were recovered in EP tubes. Repeat the above steps three times, and make the total volume of the quantum dot solution not exceed 50 μL for the last time. Use a micropH meter to detect the pH of the quantum dot solution and adjust the pH value to 7.2.

[0028] (2) Activation: Weigh 2 mmol of EDC and 0.5 mmol of NHS in an ice box with humidity less than or equal to 30% and 0-4°C, and quickly add them to the quantum dot solution obtained in step (1), and vortex After oscillating evenly, place on a shaker to react for 50 minutes at a reaction temperat...

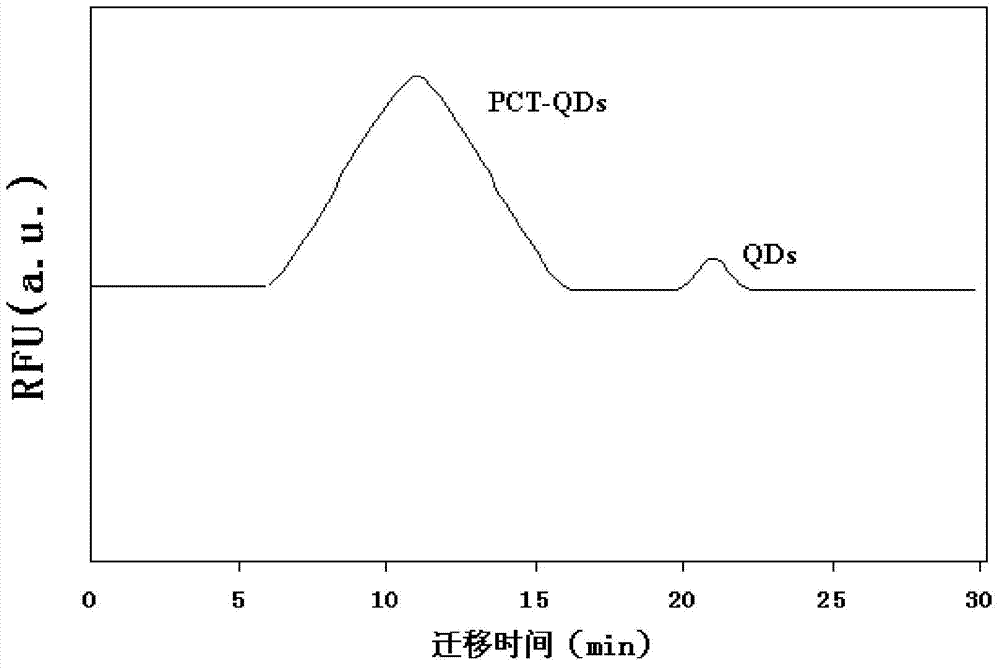

Embodiment 2

[0036] (1) Cleaning of quantum dots: Take 10 μL of 8 μmol / mL CdTe / ZnS core-shell quantum dots in EP tube, and add 2 mL of 10 mmol / L, pH=7.5 phosphate buffer into the EP tube, mix well and use 100K ultrafiltration The tube was centrifuged at 8000r / min at 25°C for 8min, and the quantum dots were recovered in EP tubes. Repeat the above steps three times, and make the total volume of the quantum dot solution not exceed 50 μL for the last time. Use a micropH meter to detect the pH of the quantum dot solution and adjust the pH value to 7.5.

[0037] (2) Activation: Weigh 2.5mmol EDC and 0.5mmol NHS in an ice box with a humidity less than or equal to 30% and 0-4°C and quickly add them to the quantum dot solution obtained in step (1), shake evenly with a vortex oscillator Then place it on a shaker and react for 80 minutes at a reaction temperature of 25° C. to obtain an activated quantum dot solution.

[0038] (3) Second cleaning of quantum dots: Add 2mL of 50mmol / L, pH=8.5 borate b...

Embodiment 3

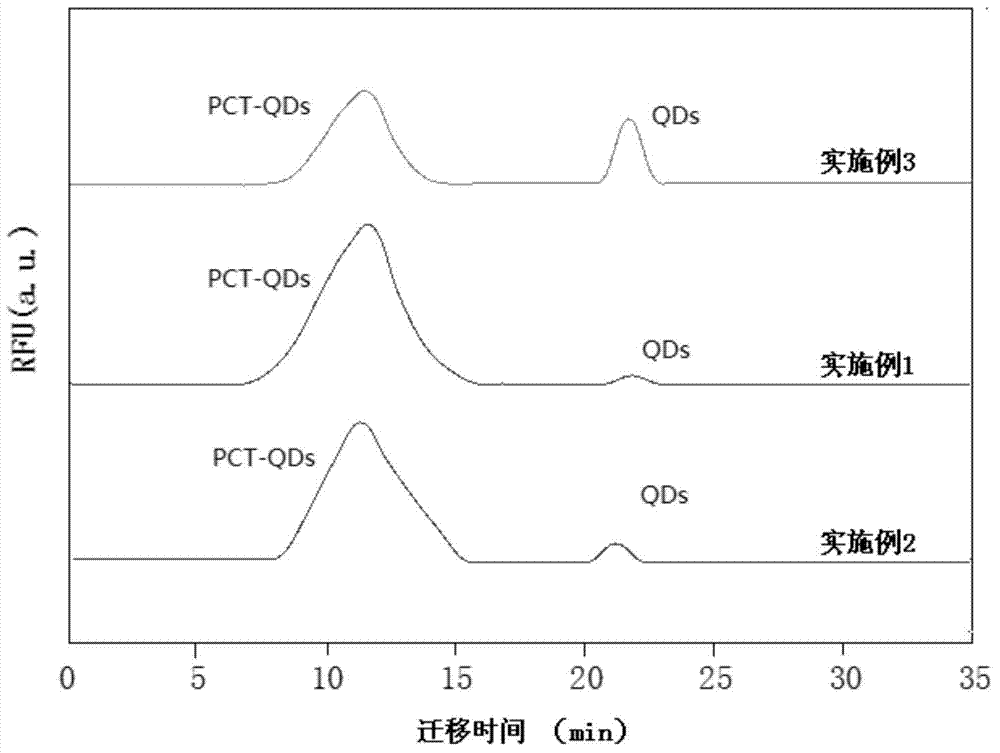

[0044] The difference between this implementation and Examples 1 and 2 is that the labeling efficiency is significantly reduced by using labeling conditions outside the range of the key parameters in the specification.

[0045] (1) Cleaning quantum dots: Take 10 μL, 8 μmol / mL CdTe / ZnS core-shell quantum dots in the EP tube, and add 2 mL, 10 mmol / L, pH=7.4 phosphate buffer into the EP tube, mix well Use a 100K ultrafiltration tube to centrifuge at 7000 r / min at 25°C for 8 min, and recover the quantum dots in EP tubes. Repeat the above steps three times, and make the total volume of the quantum dot solution not exceed 50 μL for the last time. Use a micropH meter to detect the pH of the quantum dot solution and adjust the pH value to 7.5.

[0046] (2) Activation: Weigh 2.5mmol EDC and 0.5mmol NHS in an ice box with a humidity less than or equal to 30% and 0-4°C and quickly add them to the quantum dot solution obtained in step (1), shake evenly with a vortex oscillator Then plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com