Manufacturing process of subminiature-structure capacitor

A manufacturing process and capacitor technology, which is applied in the field of ultra-small foil series structure film capacitor products, can solve the problems of insufficient service life, large contact loss, etc., achieve strong moisture resistance, temperature shock resistance, and low high frequency loss , the effect of high capacity accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with the best embodiment.

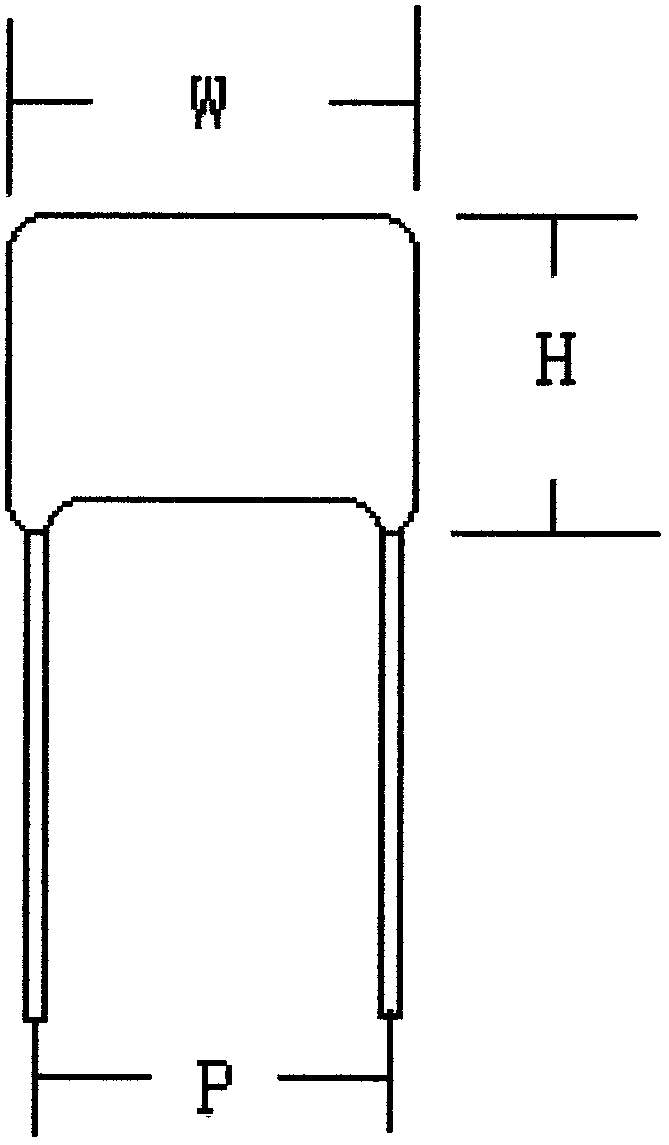

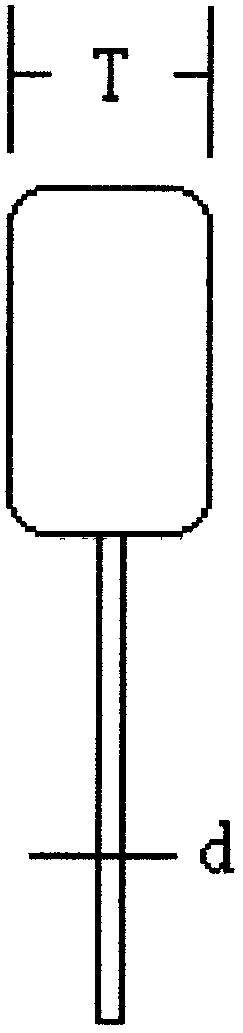

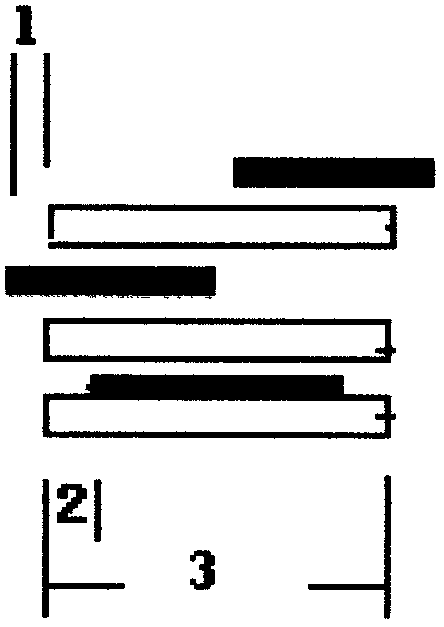

[0017] like Figure 1-3 As shown, the manufacturing process of ultra-small structure capacitors includes the following processes: winding, hot pressing, gold spraying, welding, and encapsulation; using the existing 3mm thick aluminum foil for 7.5 pitches as electrodes, using three-layer electrodes , a layer of dielectric is set under each electrode, and the top layer of electrodes and the middle layer of electrodes protrude from the edge of the dielectric respectively; the end surface of the electrode is connected with the aluminum foil by the gold spray layer, and the lead wire is welded to the end surface of the gold spray layer; the medium and the electrode roll Winding and powder epoxy encapsulation to make capacitors.

[0018] The metallized film coating and aluminum foil are used as electrodes; the metallized film is used as a medium. It has self-healing characteristics and stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com