Preparation method of dielectric film for improving capacity extraction rate of solid electrolyte tantalum capacitor

A solid electrolyte, tantalum capacitor technology, applied in the direction of solid electrolytic capacitors, capacitor dielectric layers, capacitor parts, etc., can solve the problems of uneven pressing density, poor fluidity of tantalum powder, narrow pores of anode tantalum blocks, etc., to improve impregnation. process, the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

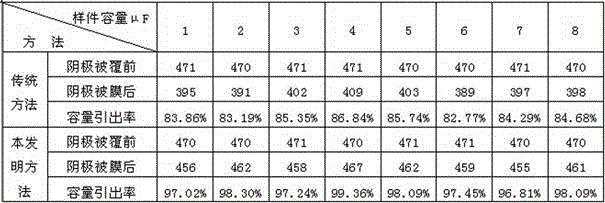

Examples

Embodiment 1

[0015] 1) Press the tantalum powder with a specific volume of 70,000 V·μF / g into a 10V470μF anode tantalum block according to the conventional method;

[0016] 2) Sintering the anode tantalum block at high temperature according to the conventional method;

[0017] 3) Immerse the high-temperature sintered anode tantalum block in the manganese nitrate solution at a rate of 0.5 mm / min for 4 minutes, and the immersion depth is 1 / 4 of the height of the anode tantalum block;

[0018] 4) Immerse the above anode tantalum block in the above manganese nitrate solution at a speed of 1.5 mm / min for 3 minutes;

[0019] 5) Take out the anode tantalum block from the manganese nitrate solution at a speed of 1.5 mm / min, and then put it into the decomposition furnace to prepare the manganese dioxide dielectric film according to the conventional method.

Embodiment 2

[0021] The steps are the same as in Example 1; wherein, the immersion speed in step 3) is 1.5 mm / min, the holding time is 2 minutes, the immersion depth is 1 / 5 of the height of the anode tantalum block, and the immersion speed in step 4) is 0.5 mm / min, the retention time is 5 minutes, and the removal speed in step 5) is 0.5mm / min.

Embodiment 3

[0023] The steps are the same as in Example 1; wherein, the immersion speed in step 3) is 1 mm / min, the holding time is 3 minutes, the immersion depth is 1 / 5 of the height of the anode tantalum block, and the immersion speed in step 4) is 1 mm / min, the retention time is 4 minutes, and the removal speed in step 5) is 1mm / min.

[0024] In above-mentioned each embodiment, each technical parameter of described manganese nitrate solution is all identical with the manganese nitrate solution that traditional common method adopts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com