Enhanced multi-photon imaging resolution method

A multi-photon and photo-curing technology, applied in optics, additive processing, optomechanical equipment, etc., can solve problems such as limiting the imaging resolution of 3D structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

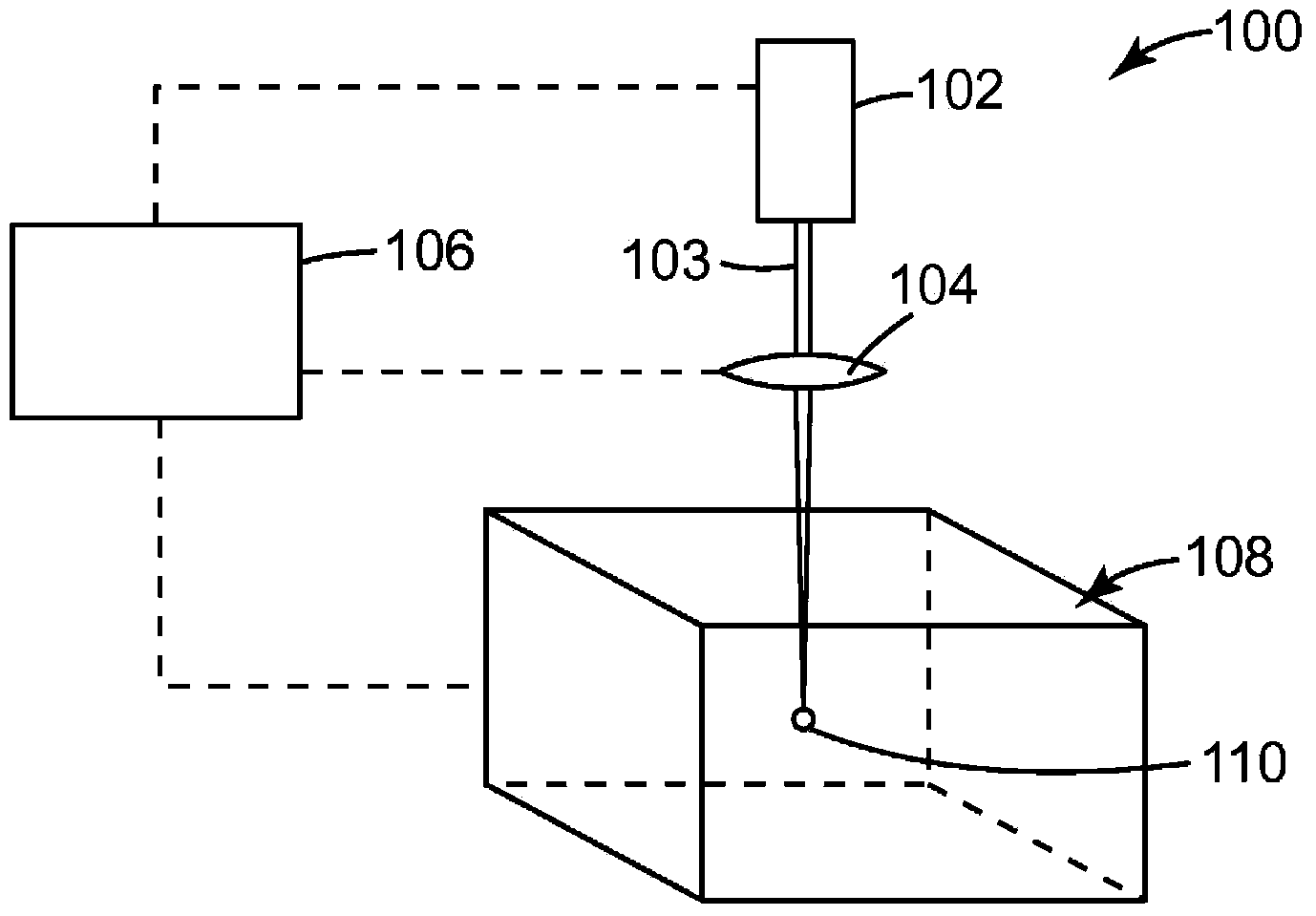

Method used

Image

Examples

example 2 and comparative example 1-2

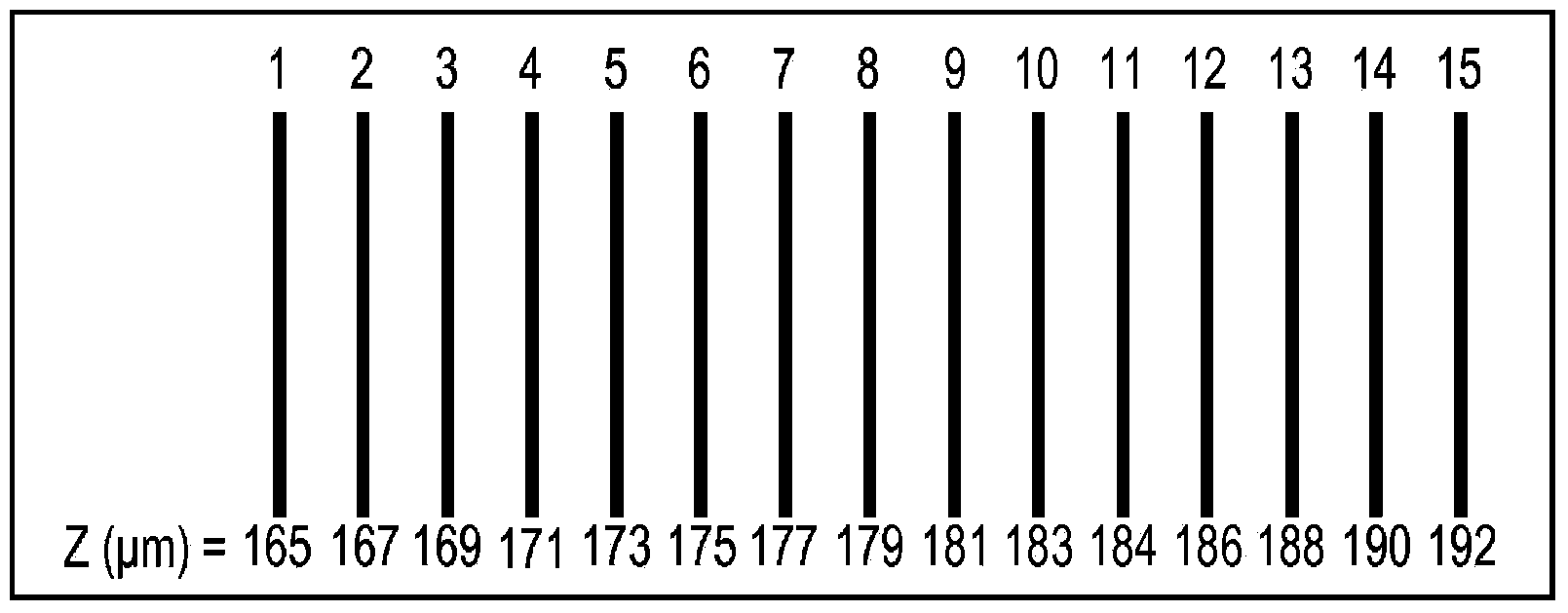

[0140] Example 2 and Comparative Examples 1-2. Voxel size measurement

[0141] Four membranes were prepared according to Example 2 and Comparative Examples 1-w, and a cube with dimensions 50 μm x 50 μm x 10 μm was written using Waverunner laser / scanner control software (manufactured by Nutfield Technology, Hudson, NH), With writing the flakes at a pitch of 0.5 μm, each flake is filled with hatched lines also written 0.5 μm apart. Use appropriate laser power levels and varying speeds. The surface roughness of the developed samples was measured by non-destructive optical interferometry and is shown in Table 2.

[0142] Table 2

[0143] Surface roughness of membrane samples versus scan speed

[0144]

[0145] Example 2 has higher surface roughness at lower speeds, indicating voxel size shrinkage as writing speed decreases (dose increases). In contrast, Comparative Examples 1 and 2 did not show such higher roughness at lower writing speeds.

[0146] table 3

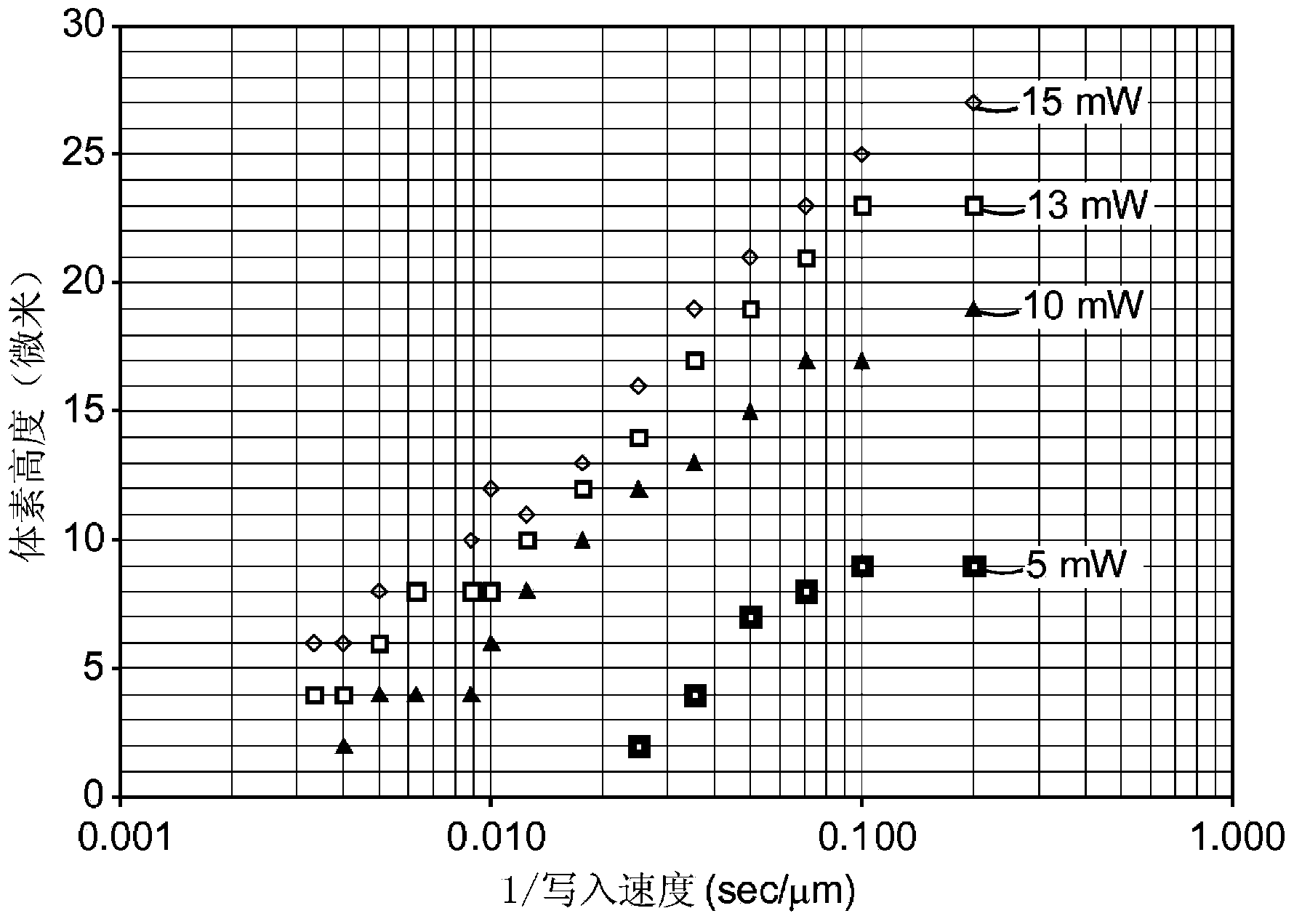

example 4-6

[0150] Films were prepared as in Example 1, substituting the sensitizers listed in Table 3 below for the 2P-photoinitiator (structure (IV)). The voxel height (proportional to dose) as a function of the inverse of scan speed was determined as in Example 1 and plotted in the figure below. Figure 5 Data showing the dyes in Examples 4-6 are shown in . There is a maximum in the plot of voxel size versus the reciprocal scan speed (dose), in at least a portion of the curve the voxel size decreases with decreasing scan speed (increasing dose). Lines in the graph are shown to illustrate trends.

[0151] The following is an exemplary embodiment of a method of increasing multiphoton imaging resolution according to aspects of the invention.

Embodiment 1

[0152] Embodiment 1 is a method of forming a three-dimensional microstructure comprising: providing a photocurable composition comprising: a prepolymer comprising an acrylate monomer and a multiphoton photon photopolymer comprising at least one distyrylbenzene dye an initiator system; and imagewise exposing at least one voxel of the photocurable composition to a dose of electromagnetic energy under conditions effective to photodefinably form at least one solid voxel having a volumetric three-dimensional microstructure, Wherein the volume of the solid voxel varies inversely with the dose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com