A preparation method and application of a carbon-loaded magnetic fiber material with a one-dimensional core-shell structure

A magnetic fiber, core-shell structure technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of large consumption of adsorption materials, increased processing costs, and low removal capacity. , to reduce the cost of separation operation, increase the contact area, and achieve good water dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

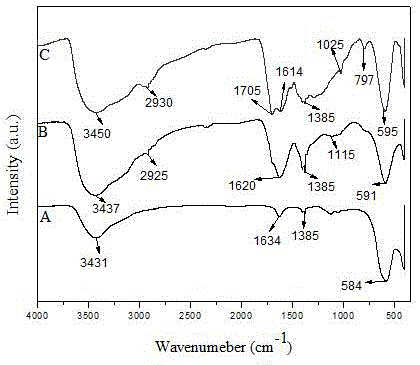

[0031] The first step, preparation of iron cobalt oxalate nanofibers:

[0032] (1) Fully dissolve 19.6g of ferrous ammonium sulfate and 7.1g of cobalt sulfate in a mixed solvent of ethylene glycol and water (500mL), and dissolve 9.45g of oxalic acid in a mixed solvent of ethylene glycol and water with the same volume ratio (500mL);

[0033] Wherein the volume ratio of ethylene glycol and water is 3:1;

[0034] (2) Add the oxalic acid solution into the mixture of ferrous iron and cobalt, stir evenly, seal the container, let it stand at 120°C for 24 hours, cool it, then filter the feed liquid to remove the solvent, recover the filtrate for later use, and put the filter cake in the air at 100°C. Air-dried for 5 hours to prepare iron-cobalt oxalate nanofibers.

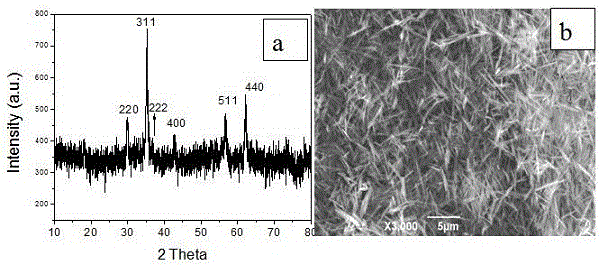

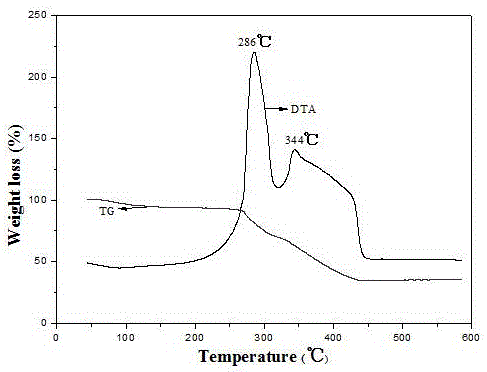

[0035] The second step, preparation of cobalt ferrite nanofibers:

[0036] The above-mentioned iron-cobalt oxalate nanofibers were placed in a muffle furnace, and the temperature was raised to 500° C. at a rate of 1° C....

Embodiment 2

[0044] The first step, preparation of iron cobalt oxalate nanofibers:

[0045] (1) Fully dissolve 13.9g of ferrous ammonium sulfate and 7.3g of cobalt nitrate in the mixed solvent (400mL) of ethylene glycol and water recovered in Example 1, and dissolve 10.1g of sodium oxalate in the recovered B Diol and water mixed solvent (400mL);

[0046] (2) Add the sodium oxalate solution into the mixed solution of ferrous iron and cobalt, stir evenly, seal the container, let it stand at 150°C for 10 hours, cool it and filter the feed liquid to remove the solvent, recover the filtrate for later use, and put the filter cake in the air at 100°C Air-dried for 5 hours to obtain iron-cobalt oxalate nanofibers.

[0047] The second step, preparation of cobalt ferrite nanofibers:

[0048] The above-mentioned iron-cobalt oxalate nanofibers were placed in a muffle furnace, and the temperature was raised to 500° C. at a rate of 1° C. / min, and kept for 3 hours to prepare cobalt ferrite nanofibers. ...

Embodiment 3

[0054] The first step, preparation of iron cobalt oxalate nanofibers:

[0055] (1) Fully dissolve 19.6g of ferrous ammonium sulfate and 6.0g of cobalt chloride in the mixed solvent (300mL) of ethylene glycol and water recovered in Example 2, and dissolve 10.5g of sodium oxalate in the mixed solvent of ethylene glycol and water recovered in Example 2 Ethylene glycol and water mixed solvent (300mL);

[0056] (2) Add the sodium oxalate solution into the mixture of ferrous iron and cobalt, stir evenly, seal the container, let it stand at 180°C for 6h, cool it, then filter the feed liquid to remove the solvent, and dry the filter cake in the air at 100°C for 5h , to prepare iron-cobalt oxalate nanofibers.

[0057] The second step, preparation of cobalt ferrite nanofibers:

[0058] The above-mentioned iron-cobalt oxalate nanofibers were placed in a muffle furnace, and the temperature was raised to 600° C. at a rate of 5° C. / min, and kept for 2 hours to prepare cobalt ferrite nanof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com