Manufacturing method of composite material laminated plate with holes

A composite material layer and manufacturing method technology, applied in the field of composite materials, can solve the problems of reducing strength, fiber breakage, reducing the strength of composite material laminates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0023] The invention includes

[0024] Step 1. Mold preparation

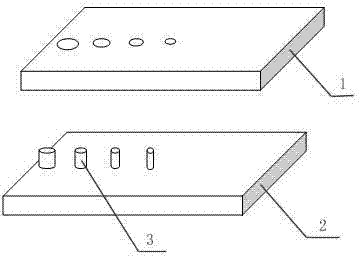

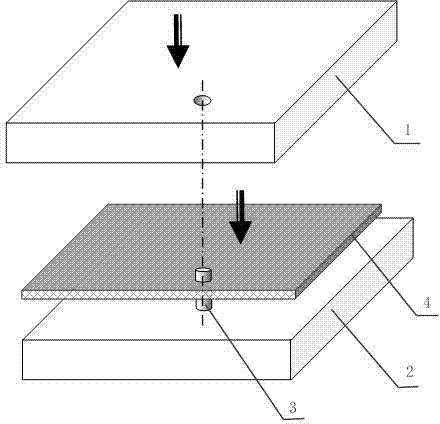

[0025] Such as figure 1 As shown, a row of through holes are set on the upper mold plate 1 and the lower mold plate 2, and pins 3 of corresponding sizes are made corresponding to the through holes of the mold plate. One end of the pin 3 is flat, and the other end is chamfered. Make the fiber easily bypass the cylindrical pin, and insert the flat end of the pin into the lower mold plate 2; the size, shape and position of the pin 3 determine the size, shape and position of the hole in the composite material laminate, and the hole in the composite material laminate is based on the actual Depends on usage;

[0026] Step 2. Fabrication and dipping of fiber cloth

[0027] Cut the fiber cloth to a suitable size according to the size of the mold, then fully soak the fiber cloth with resin, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com