Steel fiber and high-performance synthetic fiber mixed toughened RPC (reactive powder concrete) and preparation method

A technology of synthetic fibers and steel fibers, applied in the field of concrete, can solve the problems of limited toughening effect, small diameter of fine polyethylene fibers, affecting dispersibility, etc., and achieve the effects of improving mesostructure, improving mechanical toughness, and improving toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

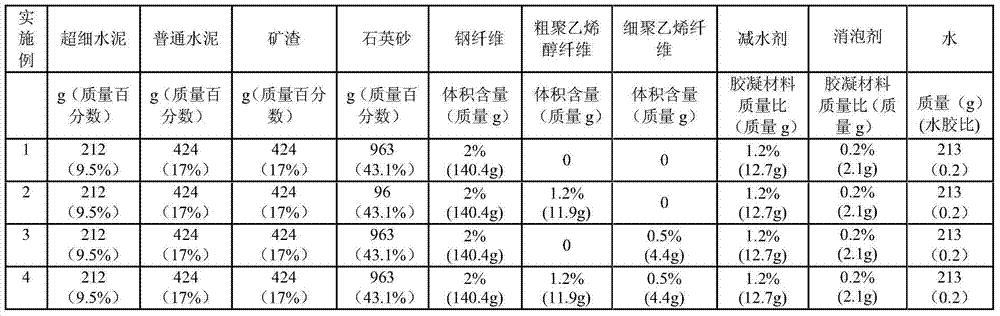

[0043] Embodiment 3 is compared with embodiment 1 and can be known, the RPC specimen that has mixed steel fiber and fine polyethylene fiber has improved 109% than the test piece toughness index that single mixes steel fiber, and the effect of improving is not very obvious, and the test piece After the first crack, the bearing capacity has an obvious jump drop.

Embodiment 4

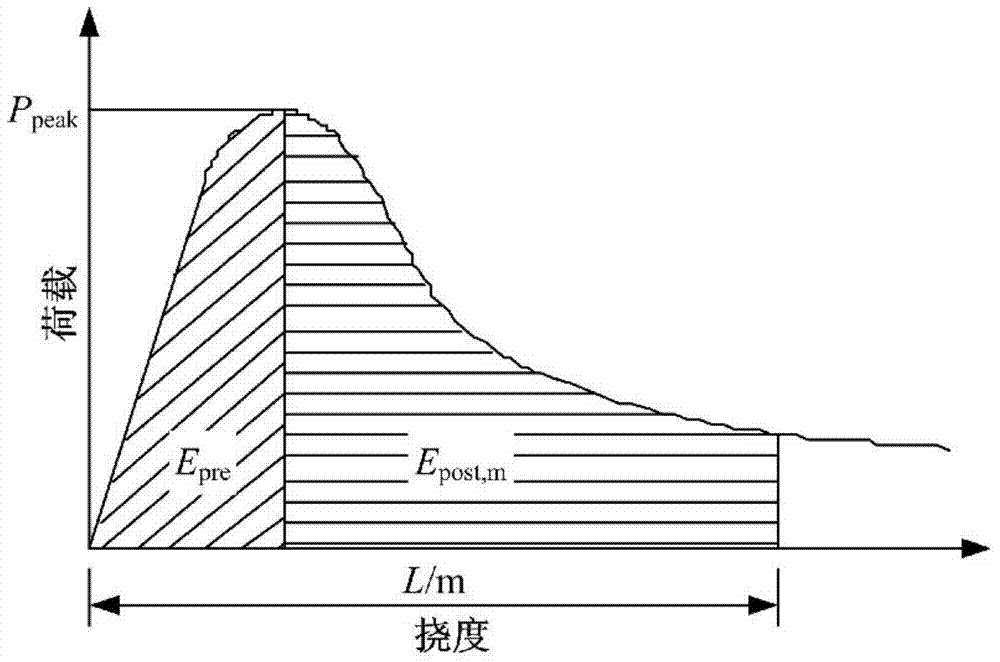

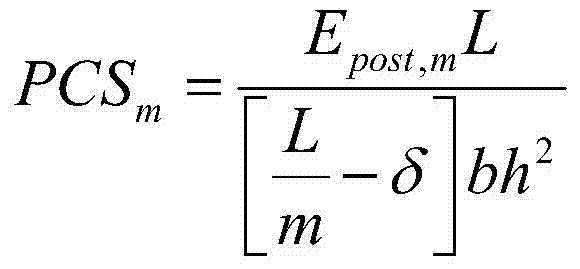

[0044] Comparing Example 4 with Examples 1, 2, and 3, it can be seen that the toughness of the test piece that is added with steel fiber, thick polyvinyl alcohol fiber, and fine polyethylene fiber is higher than that of only mixed with steel fiber, mixed with steel fiber, and coarse polyethylene fiber. Vinyl alcohol fibers, samples mixed with steel fibers and fine polyethylene fibers increased by 40%, 109%, and 185% respectively, and the toughening effect was particularly obvious. During the test, even when the specimen is damaged, the specimen still maintains a good integrity, and the bearing capacity decreases slowly after the crack appears, and has the characteristics of strain hardening and multi-crack expansion, that is, in the descending section of the full load-deflection curve , after the peak load appeared, the bearing capacity dropped for a while, and then the bearing capacity began to rise again, and two peak loads appeared, which is a characteristic that ordinary fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com